30

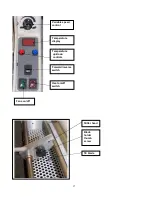

Cooling Fans

The cooling fans on the Premier 4 are used during lamination with 3-mil, 5-mil, 7-mil,

and 10-mil film. The fans cool the plastic as it leaves the laminating rollers and before it

enters the pull rollers. As mentioned earlier, the fans prevent heat wrinkling and help

insure lamination that is

smooth and flat. The pull rollers on a Premier 4 turn a little

faster than the laminating rollers, insuring that the film is perfectly flat while it is being

cooled.

NOTE:

It is possible that variances from recommended temperature settings may be

necessary due to material thickness, ambient temperature, humidity, or the quality or

thickness of the material being laminated.

Please note the wide range of temperatures listed, especially for heavier films. This

does not mean any film that thick can be run anywhere within the given range. There

are “standard” (high-temperature) and ‘low-melt” (low-temperature) versions of all film

thicknesses. Some low-melt films work at lower temperatures than others. It is

important you buy your film from a vendor who can tell you the following information

about any film you choose:

•

the thickness

•

the clarity

•

suggested melt-temperature range

•

polyester/polyethylene content

•

how well the adhesive will stick to the kinds of images you’ll be protecting and

enhancing

Temperatures may exceed 300º when laminating poster board or other thick items with

1.5-mil film on a continuous basis, but when the machine is stopped, turn the heat off if

the setting is in excess of 310º.

Never set the heat above 300º with film in the

laminator. Temperatures over 300º are not needed except with special use films.

Film that is 3 mils or thicker is generally run at 280º or less.

Special Note when using 10 mil films:

The Premier 4 is capable of laminating 10-mil films but is not designed as a

continuous 10-mil production machine. Allow occasional cooling off periods

when using film this heavy.

Summary of Contents for Premier 4

Page 25: ...25 5 3 FILM THREADING DIAGRAM ...

Page 43: ...43 ...