7

“LA” – Minimum Temperature Alarm: The

cabinet air temperature has dropped below the

programmed minimum. This alarm will continue

to display until the cabinet temperature rises

above the minimum level.

Note

: Should a “P1” or “P2” alarm occur, check

the probe wire connections to the control prior to

replacing the probe wire.

For more detailed information regarding the

Electronic Control programming and instructions,

please contact: Leer, Inc. Merchandiser Division

Customer Service. Phone: 800-766-5337. Contact

information is available on our web-site at

http://www.leerinc.com/ice-

merchandisers/merchandiser-sales-distributors/

Loading Ice:

The merchandiser should be pre-chilled prior to

loading with ice. Pre-chilling will aid the

merchandiser in reaching storage temperature at a

faster rate once loaded and reduce the risk of

melting product. Do not over fill the merchandiser

with ice!

Auto-Defrost: Avoid stacking ice above the top

edge of the air ducts that are installed on the walls

of the cabinet interior. Blocking off these air ducts

may restrict the even distribution of cold air

throughout the cabinet. This may result in warm

spots developing within the cabinet. Also, do not

stack ice high enough to block off the evaporator

fans in the unit cooler assembly. The evaporator

fans are intended to pull warm air entering the

cabinet into the unit cooler and then push that

warm air across the surface of the evaporator coil.

This process removes the heat prior to distributing

the air into the cabinet.

Maintenance and Service

Danger! This unit is charged with R290

(propane refrigerant). Propane is a flammable

and explosive gas. Component parts shall only

be replaced with like components.

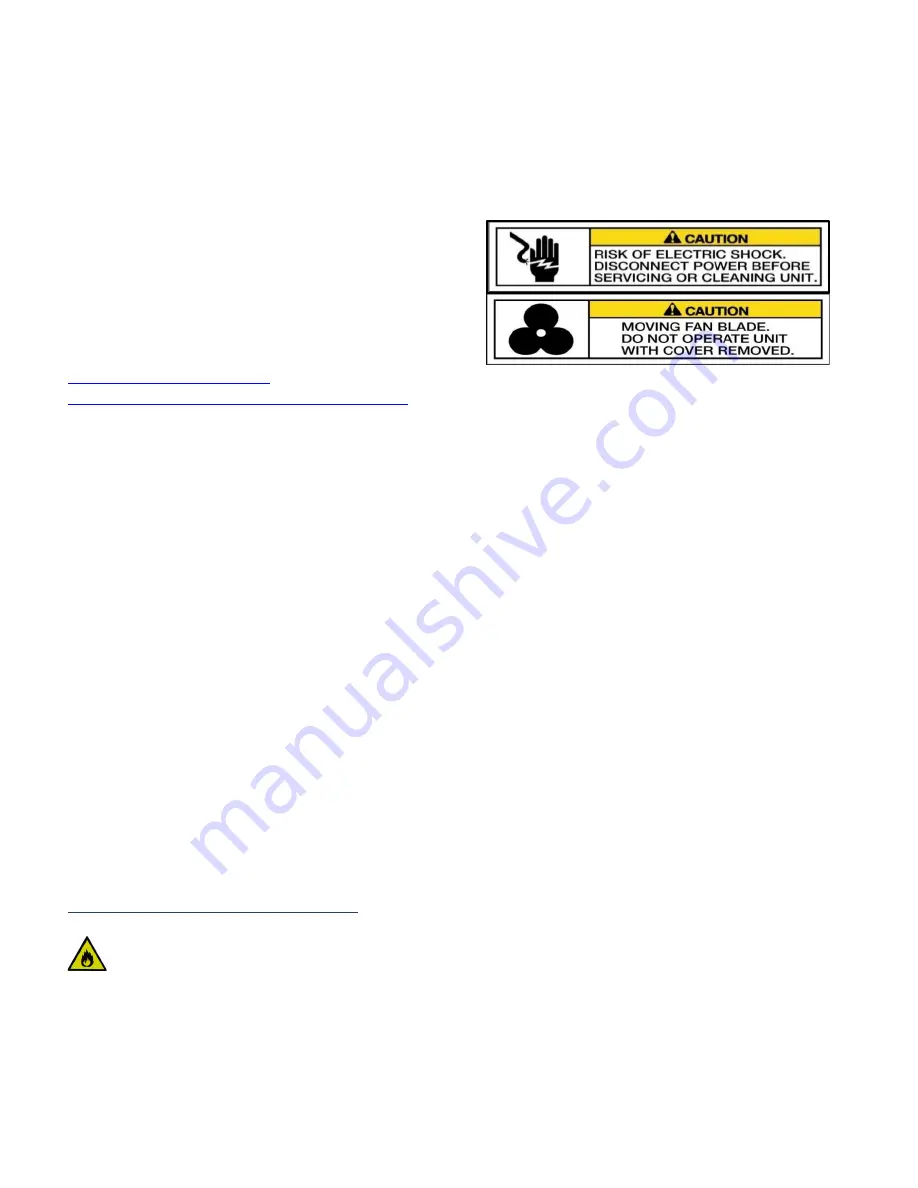

Maintenance and repair of the electrical and

refrigeration systems should only be done by

licensed, trained and qualified personnel.

Disconnect power before performing service.

Certain models may contain multiple voltages.

Leer does not assume responsibility for any

damage to people or things deriving from

violation, improper use or in any case not in

compliance with Leer’s instructions.

Cleaning the Merchandiser:

The merchandiser should be cleaned annually. In

corrosive environments such as coastal regions

and areas where deicing chemicals and road salts

are used, more frequent cleaning is recommended.

The exterior of the merchandiser can typically be

cleaned with the use of detergents dilluted in

warm water followed with a tap water rinse. The

exterior paint is capable of withstanding the use of

polishing compounds and most solvents. If using

stronger cleaning agents, they should be tested on

a small, inconspicuous areas prior to application

onto visible surfaces of the merchandiser. If

cleaning the interior of the merchandiser, the use

of detergents with strong odors (i.e. citrus based

cleaners), abrasive cleaners containing chlorine

bleach, and any form of solvent based cleaners are

not reccommended. They may leave objectionable

odors inside the cabinet which may be absorbed

by the ice being stored in the merchandiser.

Cleaning Door Gaskets:

Door gaskets may mildew and stiffen over time.

The gasket is made of a soft, flexible rubber-like

material that can be cleaned using most kitchen

and bath cleaners designed for mildew removal.

Review manufacturer information and instructions

on any cleaning agent prior to use to determine

the cleaner’s compatability with the surface being

cleaned.