4

2

1

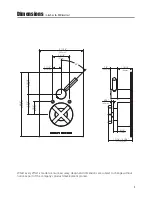

Marble wall

3 1/8 - 4 1/8”

80-105

3

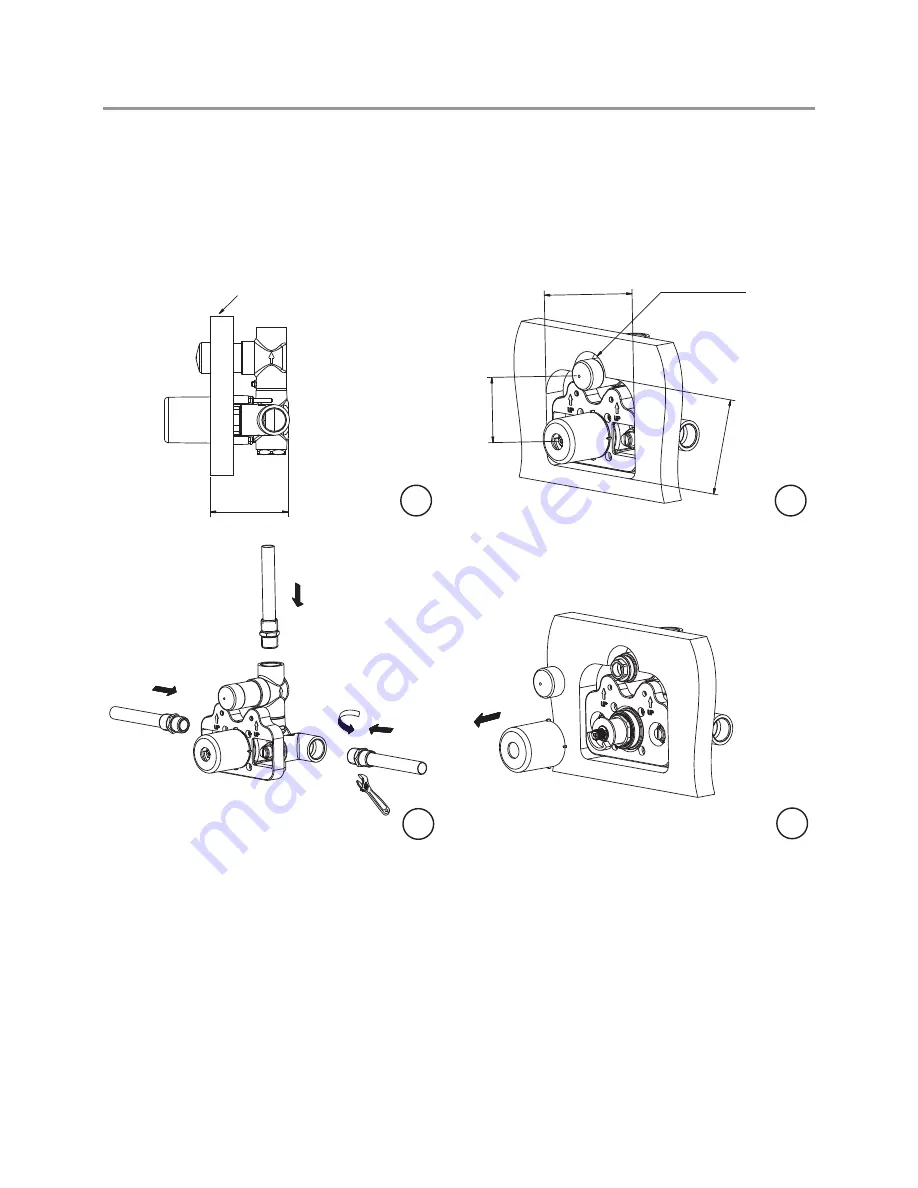

5 3/8"~5 1/2"

(136mm~140mm)

1 3/8"~1 5/8"

(35mm~42mm)

2 5/8"

(67mm)

3 9/16"~4 1/8"

(90mm~105mm)

4

Steps 1-4

Installation Procedure

Lefroy Brooks always recommends that plumbing products be installed by a licensed professional.

Shut off main water supply before installation.

1

Before installing the valve into the wall, please note that a distance between 3 1/8”~ 4 1/8”

(80mm ~ 105mm) from the wall surface to the back of valve should be left, so that it can fit the

trim

kit.

2

Install valve assembly into the wall.

3

Cut a hole on the wall surface for fitting the trim kit. The hole dimension should be as shown.

4

Throw away the protective caps only when the building construction is completed and you are

ready to fit the trim.