LOADER INSPECTION, SERVICE, AND MAINTENANCE

Lower the bucket to the ground, shut off tractor engine, and relieve the pressure in the hydraulic

system before adjusting, lubricating, or servicing the loader.

Periodically check all bolts for looseness and re

-

torque if necessary.

Before storage, be certain all hydraulic cylinders are fully collapsed so that the rod will not be

exposed to the elements or damaged.

Be certain hydraulic system remains sealed at all times to prevent contamination.

Check and maintain an adequate fluid level in the tractor reservoir prior to use.

Inspect all hydraulic system hoses and fittings. Replace prior to further operation if damaged.

Periodically inspect the two grease fittings for the engagement pins. See page 21 for adapter break

parts diagram.

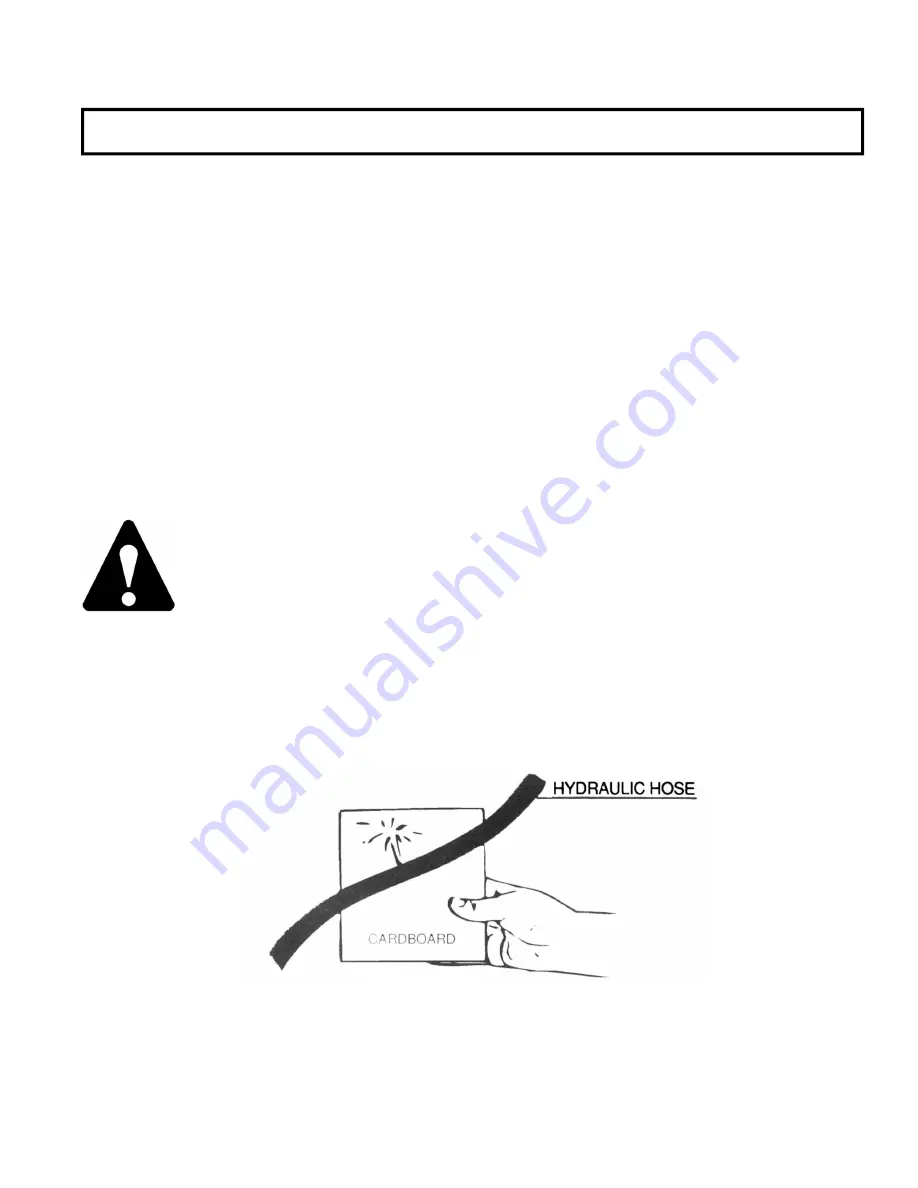

WARNING!

Escaping hydraulic oil under pressure can penetrate the skin. Never use body to

check for hydraulic leaks. Use cardboard when checking for leaks. See Fig.

13

-

1.

Relieve hydraulic pressure before disconnecting any hydraulic line. Failure to heed may result in serious

injury or death.

Page 15

FIG. 13

-

1

Summary of Contents for 780

Page 8: ...SAFETY DECALS Page 6 ...

Page 19: ...780 SL HYDRAULIC SYSTEM PARTS DIAGRAM Page 17 ...

Page 21: ...780 NSL HYDRAULIC SYSTEM PARTS DIAGRAM Page 19 ...

Page 22: ...KOYKER LEGEND 780 NSL LOADER PARTS DIAGRAM Page 20 ...

Page 25: ...KOYKER LEGEND 780 SL LOADER PARTS DIAGRAM Page 23 ...

Page 28: ...EURO GLOBALADAPTER PARTS DIAGRAM Page 26 ...

Page 30: ...BUCKET PARTS DIAGRAM Page 28 ...