6

V

VEEN

NTTIILLA

ATTIIO

ON

N ((ccoonnttiinnuueedd))

Any ventilation fitted must comply with BS 5871 part 2 and BS 5440 part 2. Ventilation fitted under, or within

immediate vicinity of the appliance must not be used as it may adversely effect performance of the ODS sys-

tem. The appliance MUST NOT be installed in a bedroom, bathroom or any sleeping area. For Republic of

Ireland, see relevant rules in force.

U

UN

NPPA

AC

CK

KIIN

NG

G TTH

HEE A

APPPPLLIIA

AN

NC

CEE

Remove the straps and the top lid of the outer packaging, remove any instructions or fixing kits.

Read ALL these instructions before continuing to unpack or install this appliance.

Lift off the remaining packaging components.

Check that the components supplied correlate with the component checklist. Please dispose of all the packag-

ing materials at your local recycling centre.

C

CO

OM

MPPO

ON

NEEN

NTT C

CH

HEEC

CK

KLLIISSTT

Q

QU

UA

AN

NTTIITTYY

D

DEESSC

CR

RIIPPTTIIO

ON

N

1

Firebox and burner assembly

1

Set of manufacturers instructions

1

Decorative frame assembly

1

Screw and wall plug pack

1

Rubber grommet

G

GA

ASS SSU

UPPPPLLY

Y R

RO

OU

UTTEESS

There are four possible entry points for the gas supply pipework to enter the appliance firebox. These entry

points are ‘knock out’ type holes.

Non-concealed gas connections may be made using the entry points at either end of the firebox or the one in

the bottom of the firebox. A concealed gas connection may be made using the knock out hole in the centre

back of the firebox. Select the most appropriate entry point and knock out the relevant holes in both the firebox

and the outer casing.

No more than 1.5m of 8mm diameter pipe must be used to avoid unnecessary pressure drops.

If a concealed gas connection is to be made, the supply pipe should always be sleeved through walls and floors

using the shortest possible route.

For concealed supply pipe routing, pipes must (where possible) be vertical and providing there is sufficient wall

thickness available, they should be placed in pipe chases. Horizontal pipe runs should be avoided. Prior to chas-

ing a solid wall, an inspection should be made to note the proximity of any cables/sockets outlets which may

already be buried. Pipes must be secured using suitable clips and protected against corrosion. Ideally factory fin-

ished protected pipework and fittings should be used. Joints should be kept to a minimum and compression fit-

tings must not be used. The pipework installation must be tested for soundness before any protection is applied

and/or the pipework and fittings are buried.

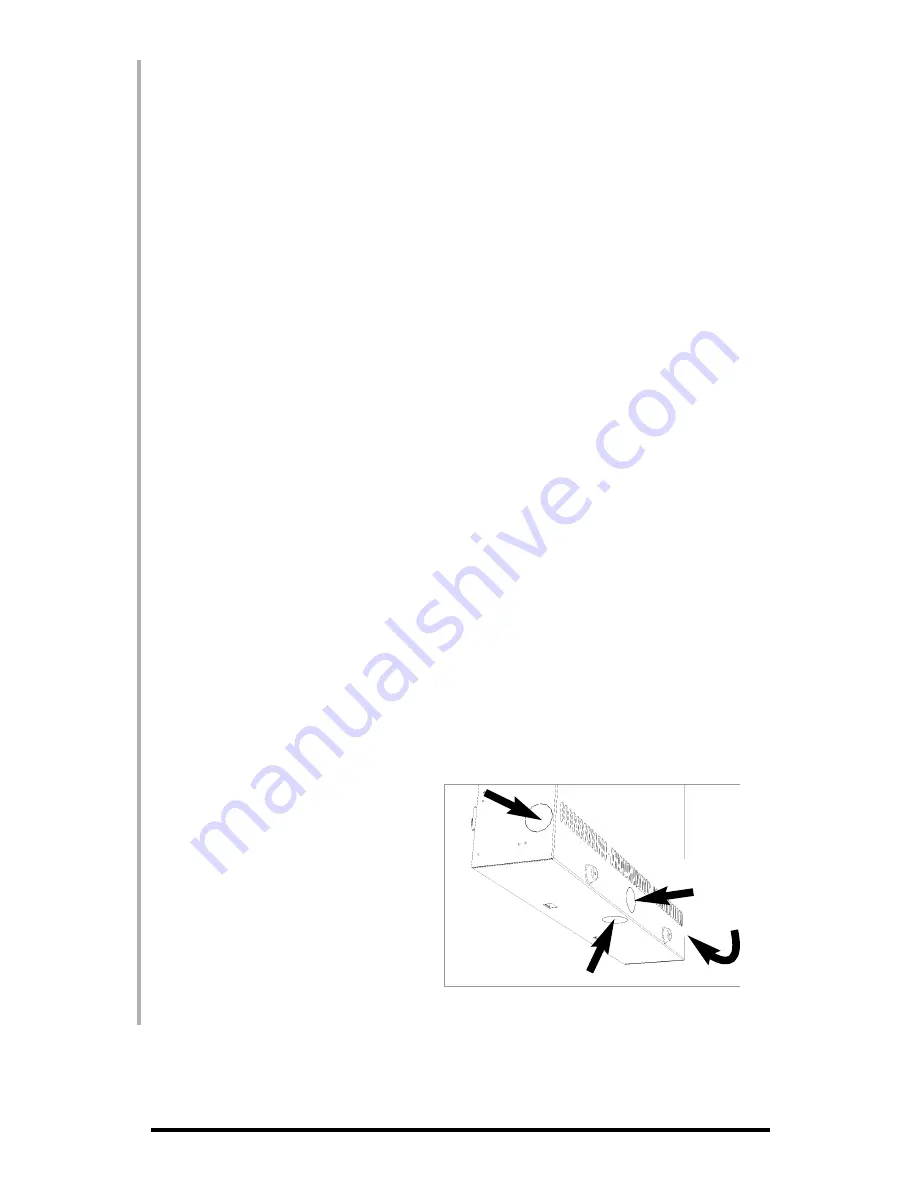

If the appliance is to be mounted on the inner leaf of

a conventional cavity wall, or a solid wall, drill the

required number of holes using a 7mm masonry bit.

Insert the fibre wallplugs as required.

If the appliance is to be mounted on a dry lined wall

or a timber framed construction wall then special

cavity screw fixings will be required which are not

supplied with this product. These should be con-

structed from metal and not plastic.

If a concealed gas connection is to be made ensure

the gas supply pipe is in it’s final position and can

enter the appliance in the correct position when the

appliance is hung on the wall.

44

55..00

55..11

66..00

44..11