11

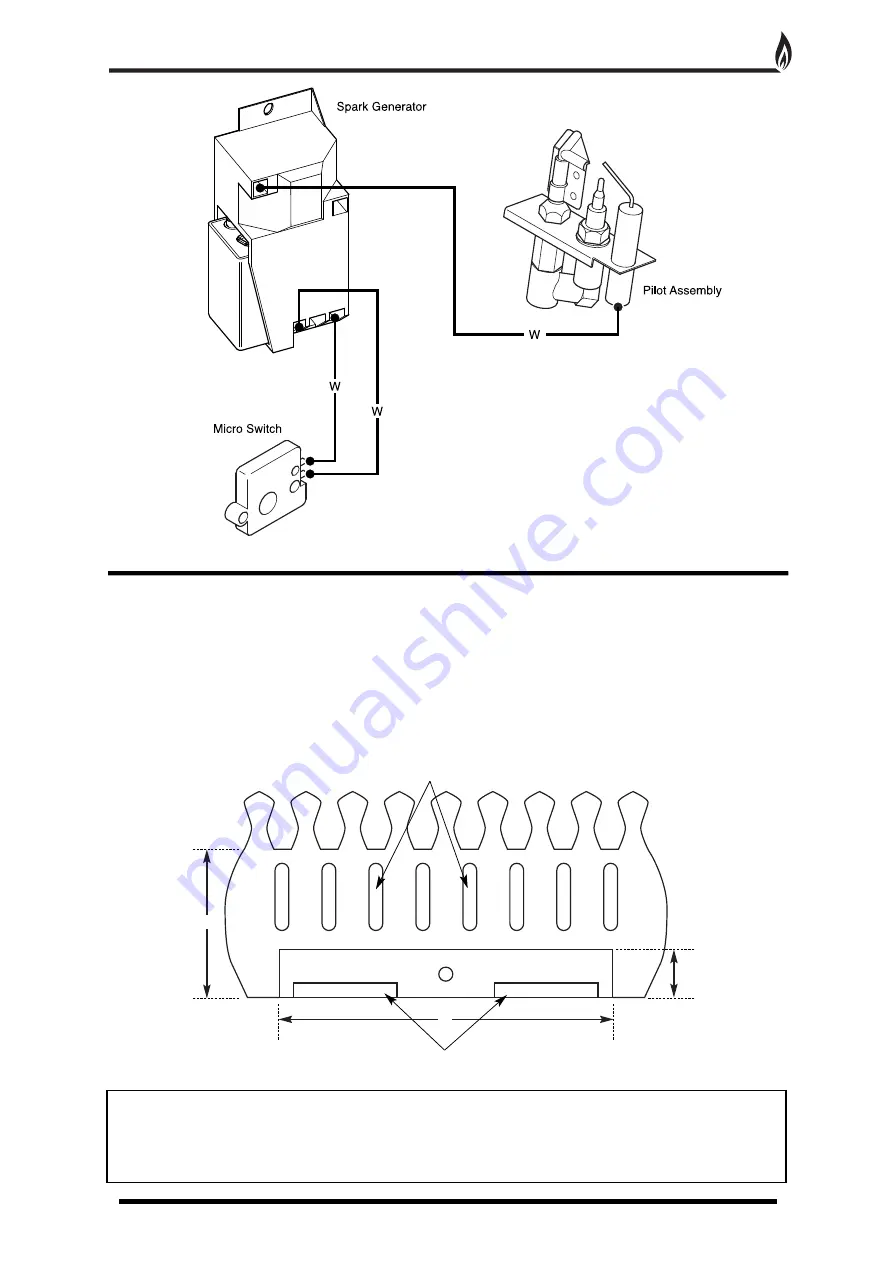

Fire fronts are now available in many different designs and finishes. The user can now choose their own

particular style of fire front to suit their individual fireplace setting, providing the fire front complies with the

following dimensions -

Fire Front -

(X) Max: 210mm

Min: 190mm

Ash Pan Cover -

(W) Max: 90mm

Min: 65mm

(Y) Max: 345mm

Min: 320mm

SAFETY WARNING - This appliance has a naked flame and as with all heating appliances a fireguard

should be used for the protection of children, the elderly and infirm. Fireguards should conform to

BS 6539 (1984 Fireguards for use with solid fuel appliances). This fire is not fitted with an integral

guard. In normal use consideration may be given to the use of a fireguard confirming to BS 6539,

such that the approach to the naked flame is minimised.

IGNITION SYSTEM WIRING DIAGRAM

FIRE FRONT SPECIFICATIONS

w

Y

X

Minimum area free space 15cm

2

Minimum area free space 5cm

2

Fig. 11

Fig. 10A