Page 16

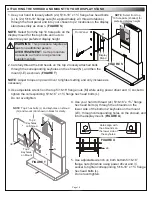

2. Carefully thread the bolt heads on the top 2 loosely attached bolts

through the corresponding keyholes on the shroud (N), and then the

mount (I-E) as shown.

(

FIGURE T

)

NOTE

: Adjust torque on power driver to lightest setting and only increase as

necessary.

3. Use adjustable wrench on the top 5/16-18” flange nuts (M) while using power driver and

½” socket to

tighten the corresponding

5/16-18” x 1¾” flange hex head bolts (L).

Do not overtighten.

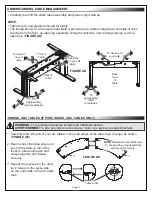

5. Use adjustable wrench on both bottom 5/16-18”

flange nuts (M) while using power driver and

½”

socket to tighten corresponding

5/16-18” x 1¾” flange

hex head bolts (L).

Do not overtighten.

4. Use your hand to thread (2x) 5/16-18” x 1¾” flange

hex head bolts (L) through the obrounds on the

lower side of the bottom 2 keyholes on the mount

(I-E), through corresponding holes on the shroud, and

into the display mount. (

FIGURE U

)

1. Use your hand to loosely attach (2x) 5/16-18” x 1¾” flange hex head bolts

(L) to (2x) 5/16-18” flange nuts (M, approximately 2-3 thread rotations)

through the front panel and into your chosen top 2 locations on the display

stand assembly as shown.

(

FIGURE S

)

NOTE

: Select from the top 10 hole pairs on the

display mount for the top bolts and nuts to

determine your preferred display height.

ATTACHING THE SHROUD AND MOUNT TO YOUR DISPLAY STAND

FIGURE S

L

Front Panel

Display

Stand

M

WARNING:

This procedure requires at

least one additional person.

AVERTISSEMENT:

Cette procédure

nécessite au moins une personne

supplémentaire.

I-E

FIGURE U

Holes align with

the obrounds on

the lower side of

the keyholes.

NOTE

: Top 2 hex bolts (L) and keyholes on shroud

(N) and mount (I-E) shown in black for clarity.

L

Top 2

Keyholes

on Shroud

Top 2

Keyholes

on Mount

I-E

N

FIGURE T

A

NOTE

: Select from top

10 hole pairs (shaded) for

preferred display height.