IMPORTANT SAFETY INSTRUCTIONS

DANGER HAZARDOUS

VOLTAGE

:

The lightning flash with the arrowhead symbol, within an

equilateral triangle is intended to alert the user to the

presence of uninsulated dangerous voltage within the product’s enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

persons.

WARNING

: A warning alerts you to a situation that could result in serious personal injury or death.

CAUTION

: A caution alerts you to a situation that may result in minor personal injury or damage to the product and/or property.

NOTE

: A note is used to highlight procedures pertaining to the installation, operation, or maintenance of the product.

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Clean only with dry cloth.

• Only use attachments/accessories specified by the manufacturer.

WARNING

: Failure to read, understand and follow the following information can result in serious personal injury, damage to the

equipment or voiding of the warranty. It is the responsibility of the Installer/User to ensure that this product is loaded according to

specifications.

WARNING

: Exceeding the weight ratings listed can result in serious injury or damage to the equipment. It is the responsibility of the

Installer/User to ensure the components installed do not surpass the weight ratings as an unstable condition can occur which may

cause possible injury or damage.

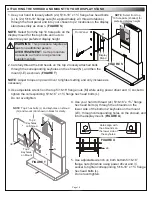

CAUTION

: Note that during construction, there must be no possibility of personal injury, for example the squeezing of fingers or

arms.

CAUTION

: If there is visible damage on the product, it must not be installed.

CAUTION

: Safety measures must be practiced at all times during the assembly of this product. Use proper safety equipment and

tools for the assembly procedure to prevent personal injury.

CAUTION

: For loading, always put heavier items at the bottom of the bays, not near the top, in order to help prevent the possibility

of the furnishing tipping over.

CAUTION

: The appliance is not intended for use by young children or infirm persons without supervision.

Safety Instructions

: Rack Mount

Elevated Operating Ambient

: If installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment may be greater than room ambient. Therefore, consideration should be given to installing the equipment in an environment

compatible with the maximum ambient temperature (Tma) specified by the manufacturer.

Reduced Air Flow

: Installation of the equipment in a rack should be such that the amount of air flow required for safe operation of the

equipment is not compromised.

Mechanical Loading

: Mounting of the equipment in the rack should be such that a hazardous condition is not achieved due to uneven

mechanical loading.

Circuit Overloading

: Consideration should be given to the connection of the equipment to the supply circuit and the effect that

overloading of the circuit might have on overcurrent protection and supply wiring. Appropriate consideration of equipment nameplate

ratings should be used when addressing this concern.

Reliable Earthing

: Reliable earthing of rack-mounting equipment should be maintained. Particular attention should be given to supply

connections other than direct connections to the branch circuit (e.g. use of power strips).

Disconnect Device (Pluggable Equipment)

: The socket-outlet shall be installed near the equipment and shall be easily accessible.

WARNING

: Middle Atlantic Products, electrical systems conform to and should be properly grounded in compliance with require-

ments of the current National Electrical Code or codes administered by local authorities. All electrical products may present a possible

shock or fire hazard if improperly installed or used. Electrical products may bear the mark of a Nationally Recognized Testing

Laboratory (NRTL) and should be installed in conformance with current local and/or the National Electrical Code.

Page 3