29

_________________________________________________________________________________________

15. SERVICE INSTRUCTIONS

15.1 Greasing of the machine

Greasing of the machine is of utmost importance in order to prevent wear in joints. Most of

the joints are service free - however the pressure roller bearing of slewing on pedestal must

be greased in accordance with the maintenance schedule, with grease containing EP

(extreme pressure) additive. Outrigger bearings and articulation bearings in all hydraulic

cylinders must be greased in accordance with the maintenance schedule.

15.2 Handling of fuel and refueling

Check fuel level and refuel if necessary (1). Before

refueling check the engine and fuel type: petrol or diesel.

In petrol engine use fuel defined by the engine

manufacturer in the engine Operators Manual.

ATTENTION!

Ignition switch of the petrol engine (2)

must be in position 1 in order that the engine will start!

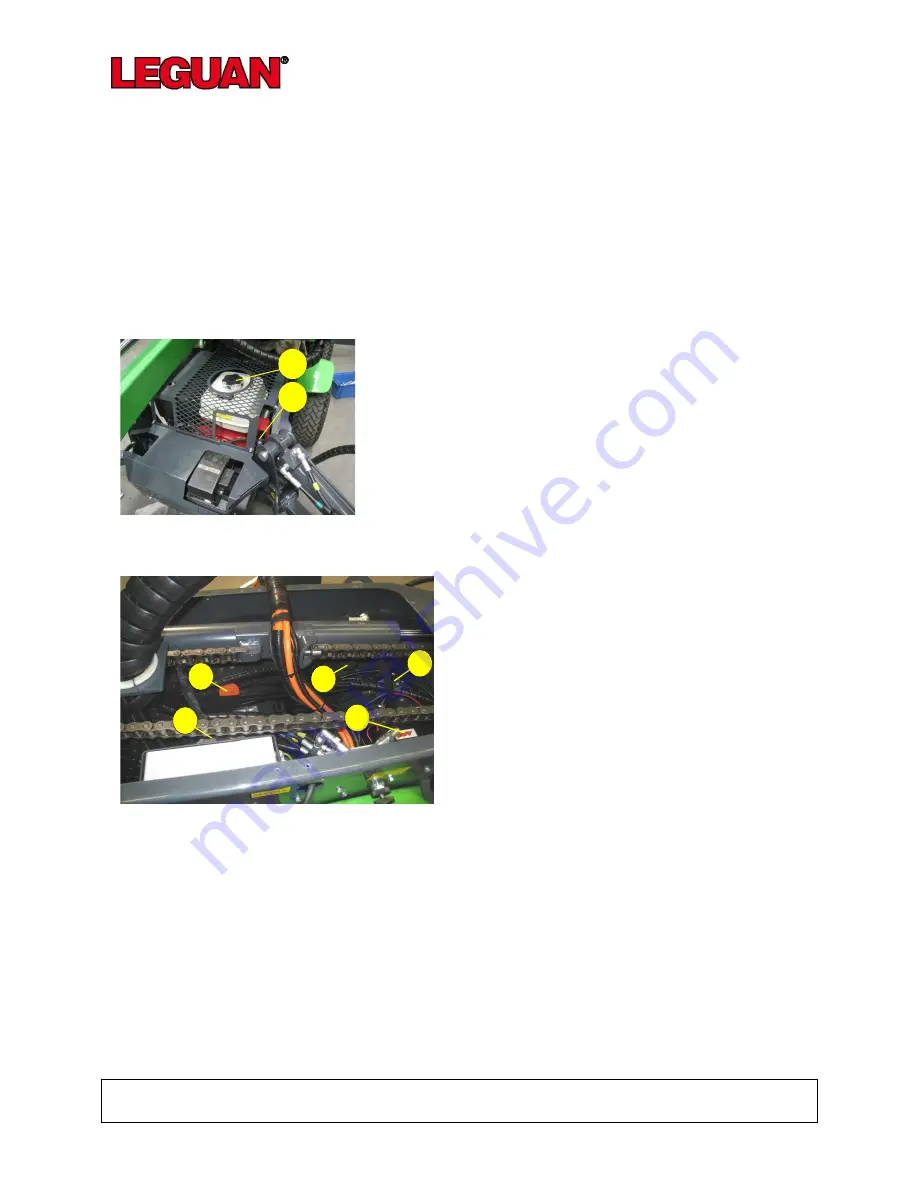

15.3 Hydraulic oil and oil filter change

Hydraulic return oil filter is located on top of the

hydraulic oil tank (no. 2) on the chassis.

Replace the filter by removing the filter cap and

replacing the filter cartridge. When changing

hydraulic oil, the oil can be removed with a suction

pump from the opening of breather cap (no 3), or

by opening the drain plug.

In both cases it is

important to clean the magnetic drain plug.

Hydraulic pressure filter cartridge ( no. 4) must be

changed always when return filter is changed.

Take off the filter bracket, lift up the filter, open

and replace the filter cartridge

15.4 Hydraulic oil level

Hydraulic oil level can be checked with the dipstick in the filler (no. 3). Oil level should be at

the upper mark in the dipstick when the booms are down on transport supports and

outriggers are down on the ground.

15.5 Battery check

In order to secure the starting and safe operation the battery must be checked regularly.

Inspect and clean battery terminals regularly. Check also condition and fastening of battery

cables and terminal insulators. Make sure that battery cables cannot chafe against any sharp

edges. Check also condition and fastening of battery disconnect switch and cables.

ATTENTION! Always clean the battery before opening the caps so that dirt cannot get

in the battery.

1

2

3

1

2

5

4