USER HANDBOOK

for stairlift type OMEGA

Edition Jan. 2004

Omega

platform lift

page 25 of 25

MAINTENANCE

It is absolutely necessary that the lift is regularly serviced.

It is recommended that a service contract be made with the supplier.

LEHNER or any of our authorised partners offers a special maintenance program adapted to

the frequency of use.

Attention!!!

When the legal provisions do not prescribe a technical approval test or a yearly

inspection carried out by a council or a civil engineer, we demand a yearly inspection of

all safety components in the course of a service. We will refuse all liability if neither a

service contract nor regular servicing is arranged.

Check-up and care

Check the following points at regular intervals, at least once a week.

1. The carriage must not start travelling until the barrier is completely folded down and the

ramp is turned down to the appropriate position.

2. It should be impossible to fold up the barriers while travelling. This should be tested

between two stop positions.

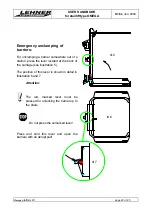

3. Check if the barriers are closed and if the ramps are folded up while travelling. If the ramps

run against an obstacle or if the user presses down the ramp, the carriage will have to stop

immediately. The linkage between barriers and ramps must be in faultless condition

(safely screwed on, no damage of the rope).

4. The carriage must stop automatically at every stop position.

5. The carriage must stop when the directional control is released.

6. The emergency stop button must put the whole stairlift out of operation.

7. If an emergency call system is in place, ensure that it works.

8. Remove dust and dirt from the tubes of the railway at regular intervals.

9. Keep the access free to the drive and to the main power switch.

Pay attention! Dust or other things must not fall into the slit on the upper tube of the railway.

For cleaning the stairlift use a damp cloth and normal household stains.

All further maintenance work is only allowed to be done by LEHNER or any of our authorised

partners.