2020-02

CANVASA II + II can filling machine operating manual

49

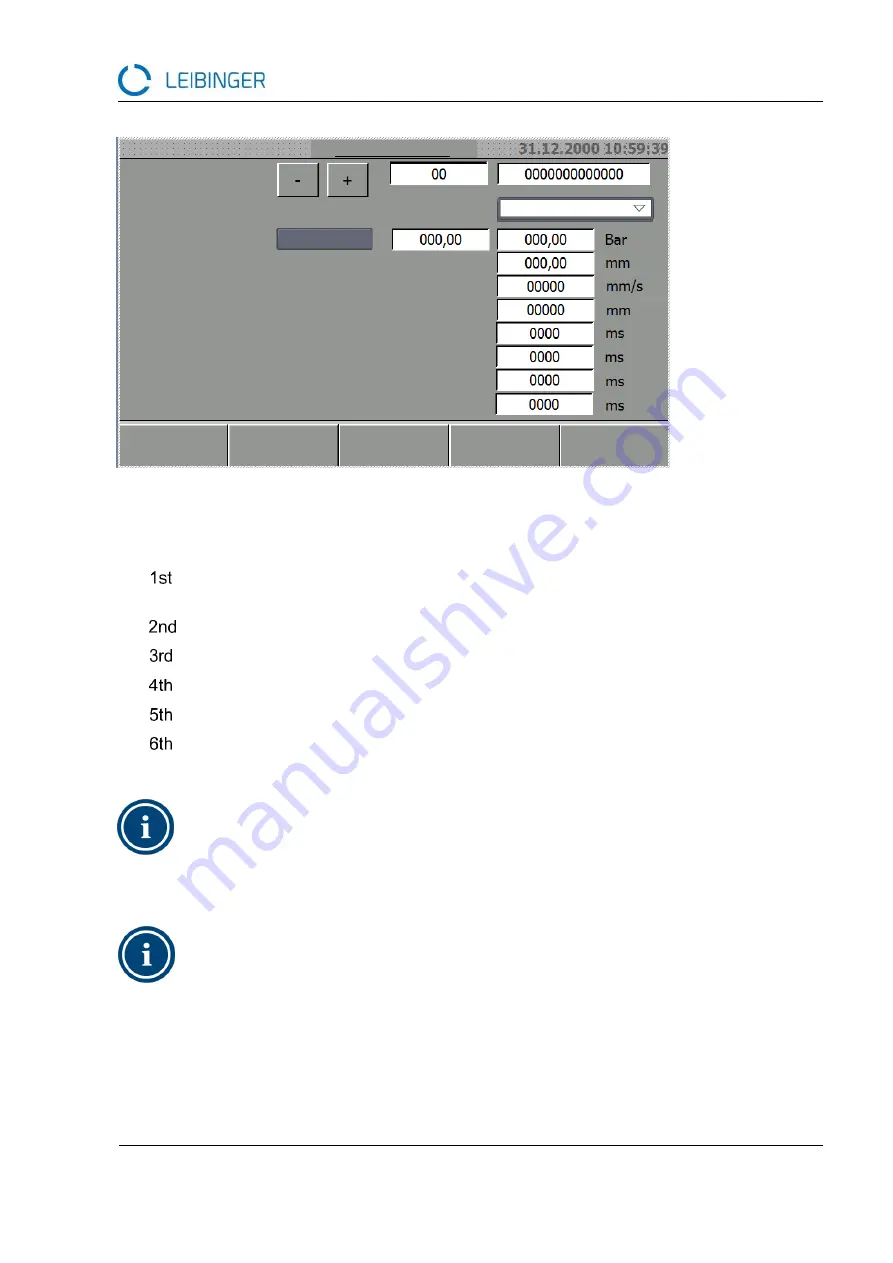

Fig. 5 Product parameters

The following sequence is recommended for adjusting the parameters:

Parameterization of the filling process until a quick, foam-free or low-foam filling is en-

sured and the desired filling quantity is reached.

Set start, duration and intensity high-pressure injection

Set bubble breaker

Check the filling quantity (e.g. by weighing)

If necessary:

Correct the filling quantity using the “Offset filling end” parameter

Pre- and bottom lid gassing setting

INFO:

Before checking the filling quantity by weighing, the exact density of the beverage must be

determined and used to calculate the correct target weight. Alternatively, a can that has

been perfectly filled (e.g. using a volumetric flask) can be weighed.

INFO:

For standard cans, changing the “Offset filling end” parameter by one millimetre is approxi-

mately equivalent to an additional filling volume of three millilitres.

After adapting the parameters, check the settings of the high-pressure injection and of the

bubble breaker again and adapt them if necessary.

Save parame-

ters

Next screen

Product:

Product management

Can type:

High-pressure injection duration:

Begin high-pressure injection:

Bubble breaker duration:

Begin bubble breaker:

Filling acceleration:

Filling speed:

Offset filling end:

Preload pressure:

Relative

Menu

BACK

Operation