2020-02

CANVASA II + II can filling machine operating manual

61

12.

Faults

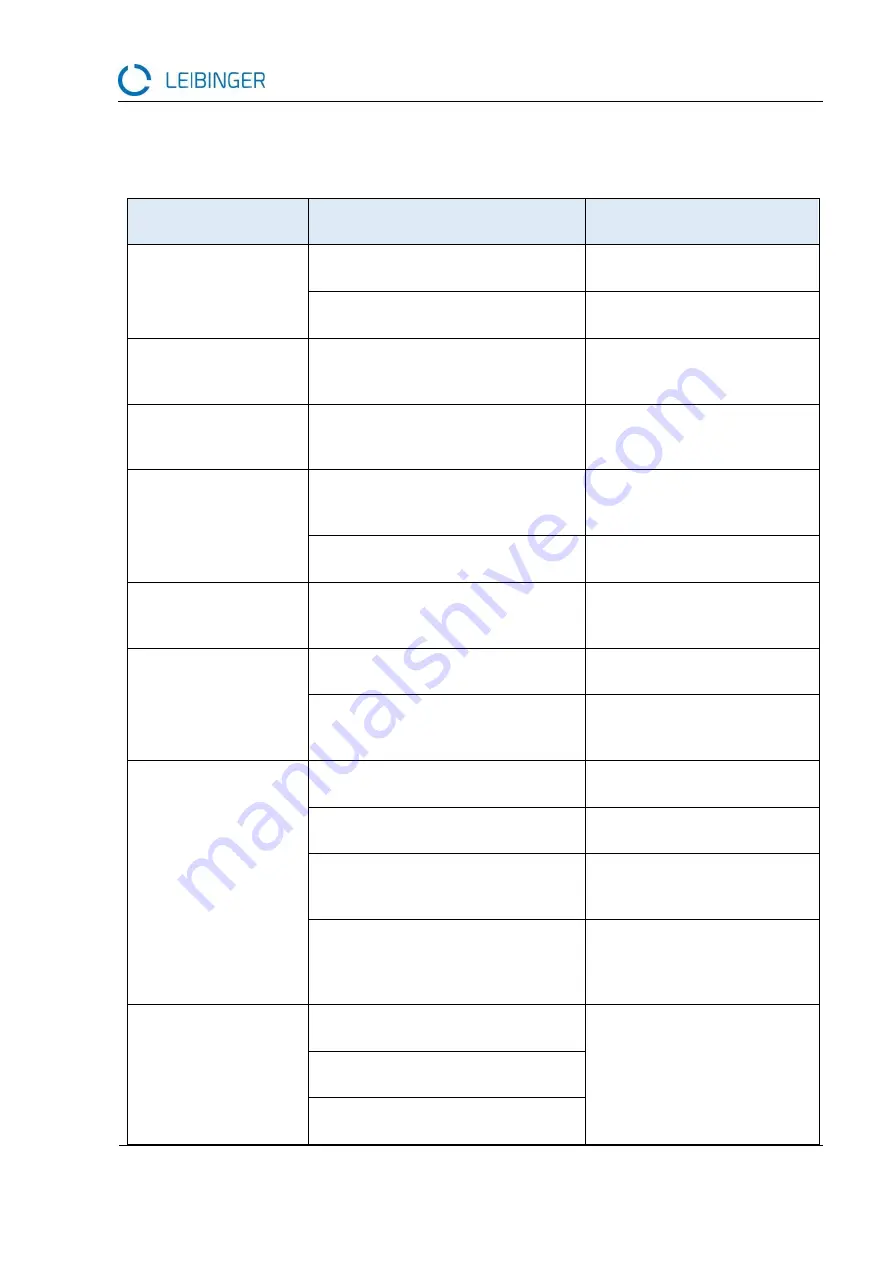

Fault

Possible cause

Remedy

Machine cannot be

switched on

Main switch not switched on

Switch on main switch

Fuse defective

Notify specialist, replace fuse

Product is discontin-

ued

Seals damaged or obsolete

Replace seals

No air pressure pre-

sent

Supply line defect

Check supply line and repair

if necessary

Can not completely

filled

Leakage, damage to contact rub-

ber

Replace seals

Filling tube not correctly mounted

Check filling tube

No or low pressure in

the supply line

Filling pressure in tank too low

Establish the right pressure

in the tank

The beverage foams

over the can when it

is removed from the

filling valve

Inside of can soiled

Ensure cleanliness of cans

Incorrect parameter for the relief

height

Correct parameters

Excessive formation

of foam

Beverage too warm

Check filling temperature

Tank pressure too high

Check pressure

Air enters product line at start of

work

Briefly open filling valves

Incorrectly selected product pa-

rameters (e.g. filling speed too

high)

Parameter adjustment

Extraordinary heating

of the motor or motor

hums when switched

on

Failure of a phase

Notify specialist

Loose clamp connection

Defective contactor