2020-02

CANVASA II + II can filling machine operating manual

74

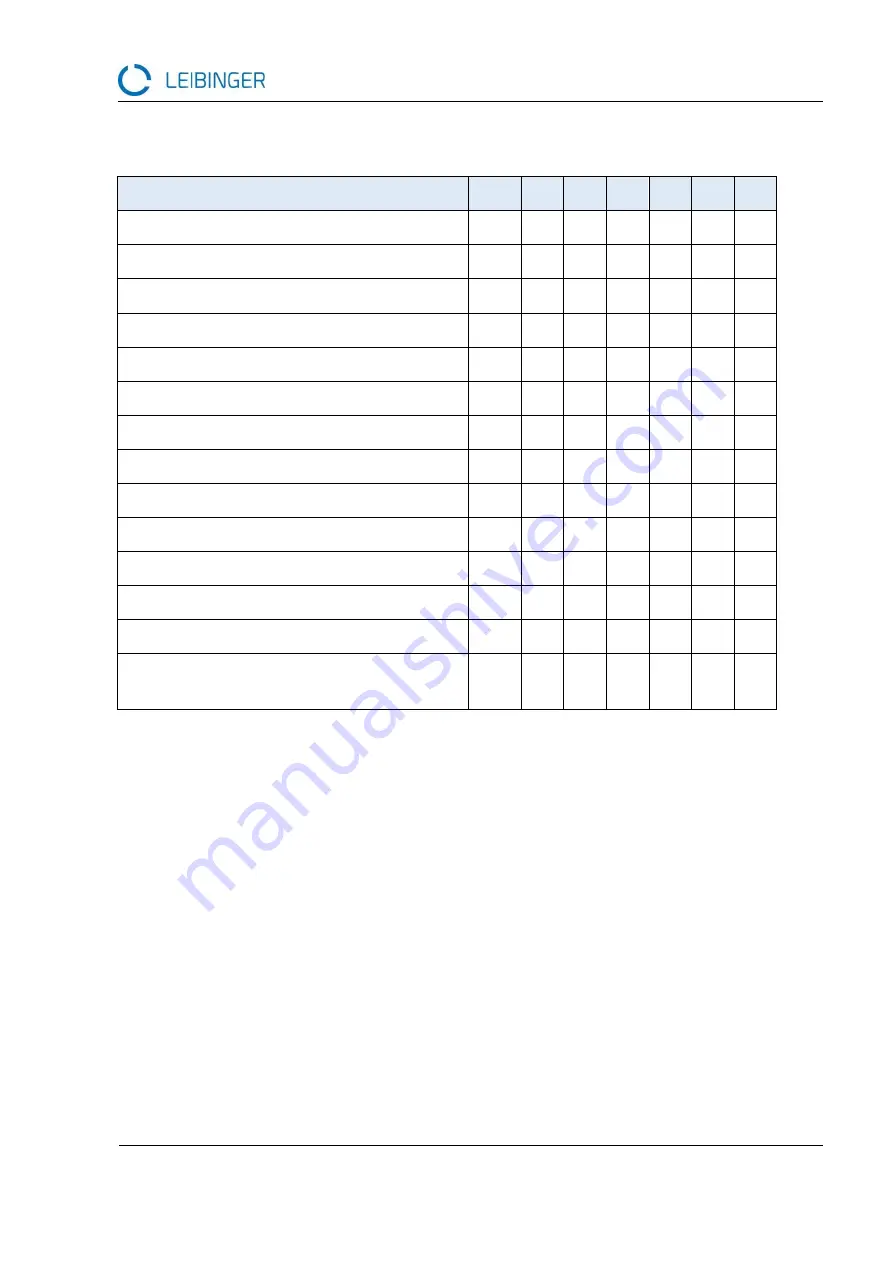

Maintenance plan

Work to be carried out

d

w

m

q

y

U

P

External cleaning

X

Clean product lines

X

Grease sealing rollers

X

Grease filling valve

X

Check positioning of rotary star wheel

X

Check sealing strokes

X

Checking the safety functions

X

Check emergency-stop button function

X

Check function of safety hinge

X

Leakage checks on the pneumatic compo-

nents

X

Testing according to DGUV Regulation 3

X

Clean the filter on the control cabinet

X

Check water filter and replace if necessary

X

Check all bearings (or after 1000 operating

hours)

X

d = daily (before start of production)

w = weekly

m = monthly

q = quarterly

y = yearly (or after 2000 operating hours)

U = after changing the set-up

P = after each production run