2020-02

CANVASA II + II can filling machine operating manual

15

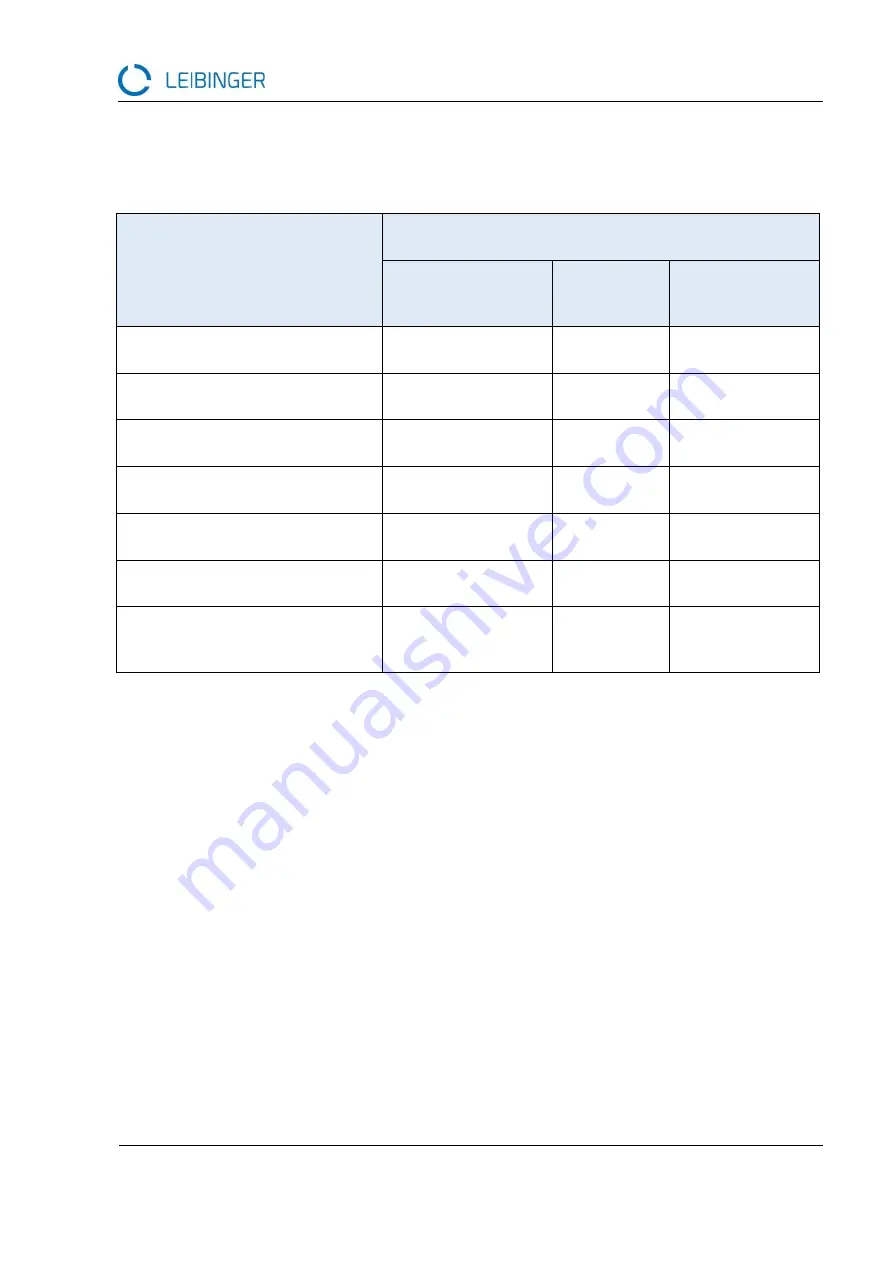

Qualification for certain activities

Activity

Qualification

Trained operators

Specialist per-

sonnel

Qualified electri-

cians

Operation in set-up mode

●

Operation in automatic mode

●

Set-up, changing the set-up

●

Troubleshooting

●

●

●

Maintenance

●

●

Work on electrical equipment

●

Work on pneumatic or hydraulic

equipment

●