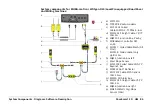

System Components, Diagrams, Software Description

PaveSmart 3D UM

83

3.2

System Wiring Diagrams

General information

The system wiring is dependent on the purchased/installed solution. The main installation is

identical, only the serial port sensor combination may vary depending on the sensor equip-

ment used. It is possible to attach up to four Robots (when linked to machines using CANBus

interfaces) or up to 2 GPS sensors.

•

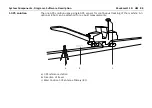

The MPC1310 must be mounted with the bracket supplied. The rear of the MPC1310

should be free from obstructions to allow sufficient cooling.

•

Mast(s) must be fixed firmly to the frame of the machine so minimum vibration is expe-

rienced.

•

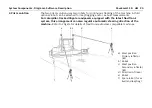

Slope sensors must be mounted at the appropriate point of the machine with the arrow

facing

forward in direction of production.

Use the machine-manufacturer-supplied slope sensor mounting bracket wher-

ever possible.

•

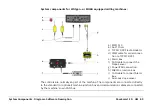

Where applicable: Alternatively to the TCPS27S or TCPS29S ruggedised radio modems,

approved third party radio modems, such as MCR-900, with appropriate cables can be

used. Refer to the Leica PaveSmart 3D Technical Reference Manual for machine-specific

details.

Summary of Contents for MCR-900

Page 1: ...Leica PaveSmart 3D User Manual Version 5 0 English ...

Page 11: ...How to use this Manual PaveSmart 3D UM 11 ...

Page 21: ...Getting Started PaveSmart 3D UM 21 Work Screen for Milling Machines a b d c e f g h i ...

Page 27: ...Getting Started PaveSmart 3D UM 27 Work Screen Mainline Concrete Paver a b c d f g h i j e ...

Page 30: ...PaveSmart 3D UM 30 Getting Started Work Screen Trimmer a b d c e f g h i j ...

Page 99: ...System Components Diagrams Software Description PaveSmart 3D UM 99 ...

Page 107: ...Troubleshooting PaveSmart 3D UM 107 ...

Page 136: ...PaveSmart 3D UM 136 Technical Data Mounting RAM mounting Parameter Data ...