B975 User Guide

Chapter 7

Router Table Operation

53

7-16

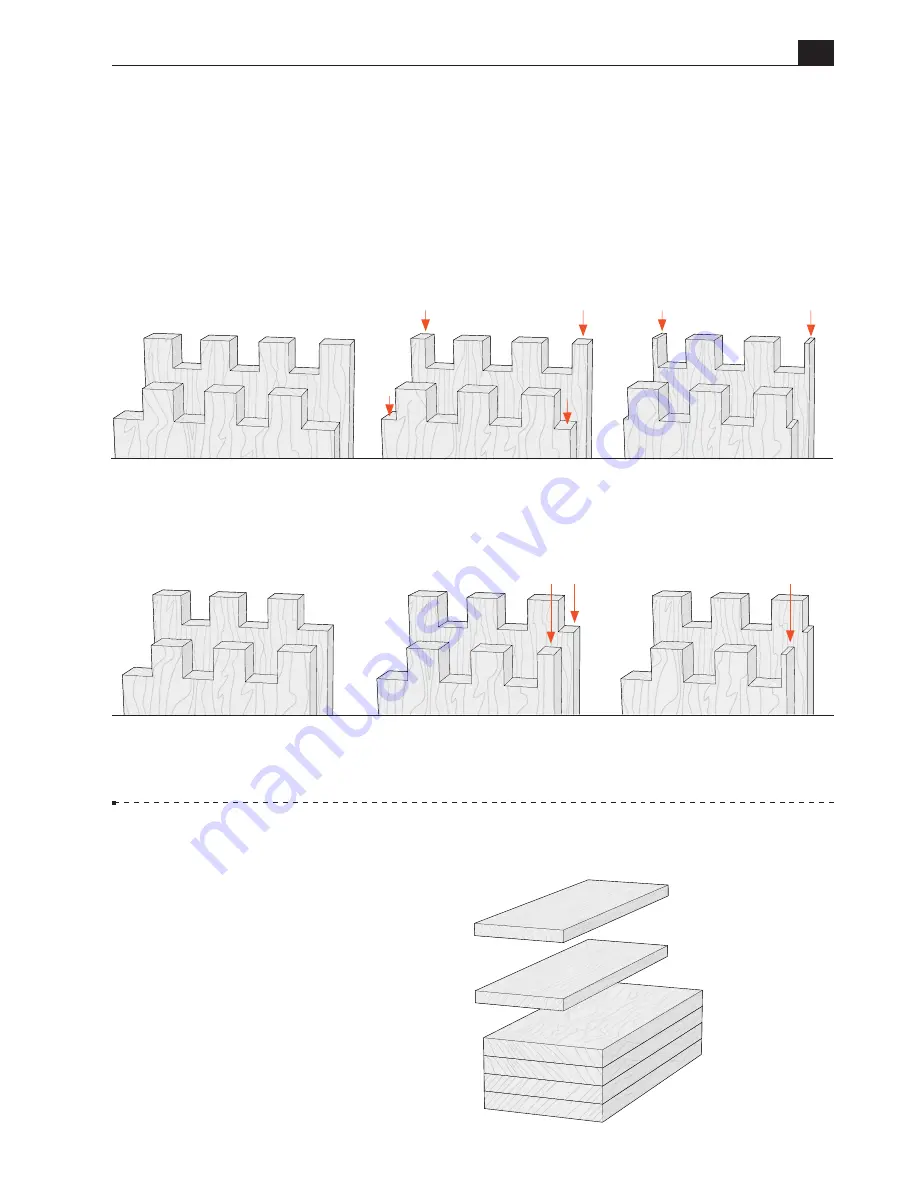

Board widths indicated in the chart on the previous page will produce full size pins and

sockets at each board edge, for symmetrical or asymmetrical joints. Symmetrical joint board

widths may be reduced as required, resulting in smaller but equally sized pins and sockets at

each board edge. If board widths are reduced for asymmetrical joints, one edge of the board will

have a full size pin and socket while the other board edge will have a smaller pin and socket.

This may result in an unattractive joint.

7-17 Making a Box

Prepare four similar boards 3/4" thick

× 5-3/16" wide by about 12" long

[19mm×133mm×305mm], and two test

boards, 3/4" thick by about 4"[100mm]

wide.

Note:

Boards of different thicknesses may

also be joined.

IMPORTANT:

Read the whole chapter before routing any boards.

Symmetrical

Asymmetrical

Full size

pins and sockets

Full size

pins and sockets

When a symmetrical board width is reduced,

the joint will have smaller, but equal sized

pins and sockets at each edge of the board.

Width specified in the board width chart

results in full size pins and sockets at each

edge of the board.

Width specified in the board width chart

results in a full size pin at one edge of the

board, and a full size socket at the other edge

of the board.

When an asymmetric board width is reduced,

the joint will have a full size pin and socket at

one edge of the board, and a reduced size pin

and socket at the other edge of the board.

When the board width is reduced further,

the result is very narrow and fragile pins at

each edge of the board.

When the board width is reduced further,

the result is a very narrow and fragile pin at

one edge of the board.

Small pin

can break easily

Reduced size

pin and socket

Small pins can break easily

Reduced size pins and sockets