41

SINGLE PASS HALF-BLIND DOVETAILS

Chapter 11

D4R Pro User Guide

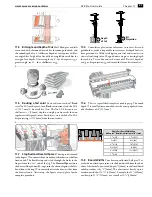

11-3 Bit Angle and Depth of Cut

Half-blind pins and tails

are routed with the

same

dovetail bit, the

same

guidebush, and

the

same

depth of cut. A different depth of cut requires a differ-

ent angled bit. Leigh offers five different angled dovetail bits for

a range of cut depths. A lesser angle, say 8˚, for a deeper cut

➀

; a

greater angle, say 18˚, for a shallower cut

➁

.

1

2

18˚

8˚

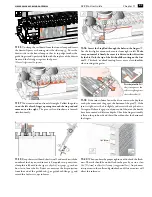

11-4

Cumulative plus/minus tolerances in routers, bits and

guidebushes, make it impossible to state exact bit depth for first-

time precision fit. All dovetail jigs require trial and error tests to

attain a fine fitting joint. The good news; we give a starting depth

for each bit. Test and measure the successful ‘Best fit’ depth of

cut

➀

or bit projection

➁

and record for future first-time fits.

1

2

Depth

of Cut

Bit

Projection

11-5 Routing a Test Joint

You need a router, the

e7-Bush

set at No.10 (see chapter 3 for

e-Bush

instructions) and the 80-8

1

⁄

2

"[12,7mm] 8˚ dovetail bit. Note: The No.80-8 bit routs at a

shallower ~

1

⁄

2

"[13mm] depth on single pass dovetails than on

regular variably spaced joints. For this test, start with the No.80-8

bit projecting

15

⁄

16

"[24mm] from the router base.

11-6

This is a typical fixed template comb type jig. The comb

depth

➀

is usually dimensioned to suit the most popular drawer

side thickness of

1

⁄

2

"[12,7mm].

1

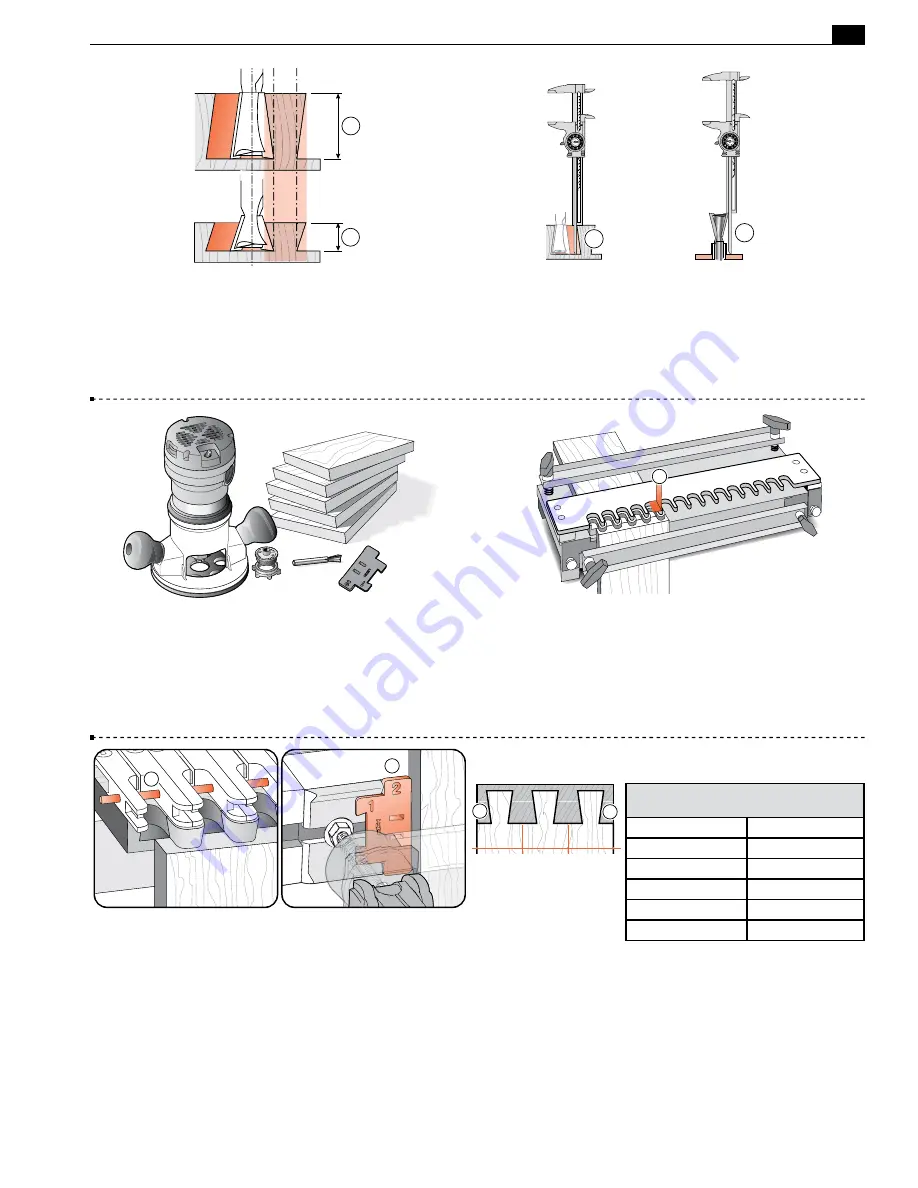

11-7 Stop Rod and Dovetail Spacer

The stop rod is inserted

in the fingers

➀

to convert them from deep tail sockets to a shallow

fixed comb. The flexible stop rod is fed through the holes in the

fingers from the “far” end of the jig. The

Dovetail Spacer

(note

the dovetail shaped notch) snaps into the channel against the left-

hand front side stop

➁

to correctly offset the drawer sides from

the drawer fronts. After setup, the Spacer stays in place for the

complete procedure.

1

2

11-8 Board Widths

To achieve equally sized half pins

➀

at

each side on a fixed space joint, use the board width from the chart

above. Alternatively, you can add up to

1

⁄

4

"[6mm] to the listed board

width, or reduce it by

1

⁄

8

"[3mm]. This chart covers boards up to a

maximum width of 13

1

⁄

16

"[331mm]. Example: the 12"[305mm]

can be up to 12

1

⁄

4

"[311mm] or as small as 11

7

⁄

8

"[302mm].

1

1

Single Pass Board Width Chart

Add up to ¼" [6mm] or subtract up to 1/8" [3mm]

2

3

⁄

16

[55]

8

11

⁄

16

[221]

3

1

⁄

4

[83]

9

3

⁄

4

[248]

4

3

⁄

8

[110]

10

7

⁄

8

[276]

5

7

⁄

16

[138]

12 [305]

6

1

⁄

2

[166]

13

1

⁄

16

[331]

7

5

⁄

8

[193]

–

Summary of Contents for D4R Pro

Page 14: ...JIG ASSEMBLY MOUNTING AND USING THE CLAMPS 6 Chapter 1 D4R Pro User Guide ...

Page 24: ...WOOD PREPARATION 16 Chapter 6 D4R Pro User Guide ...

Page 86: ...BIT SELECTION 78 Appendix II D4R Pro User Guide ...

Page 90: ...JIG PARTS 82 Appendix III D4R Pro User Guide ...

Page 92: ...PRINTED IN CANADA Joining Tradition with Today Printed in Canada ...