NOVOLAS Basic AT

Version 2.1

09/2010

52

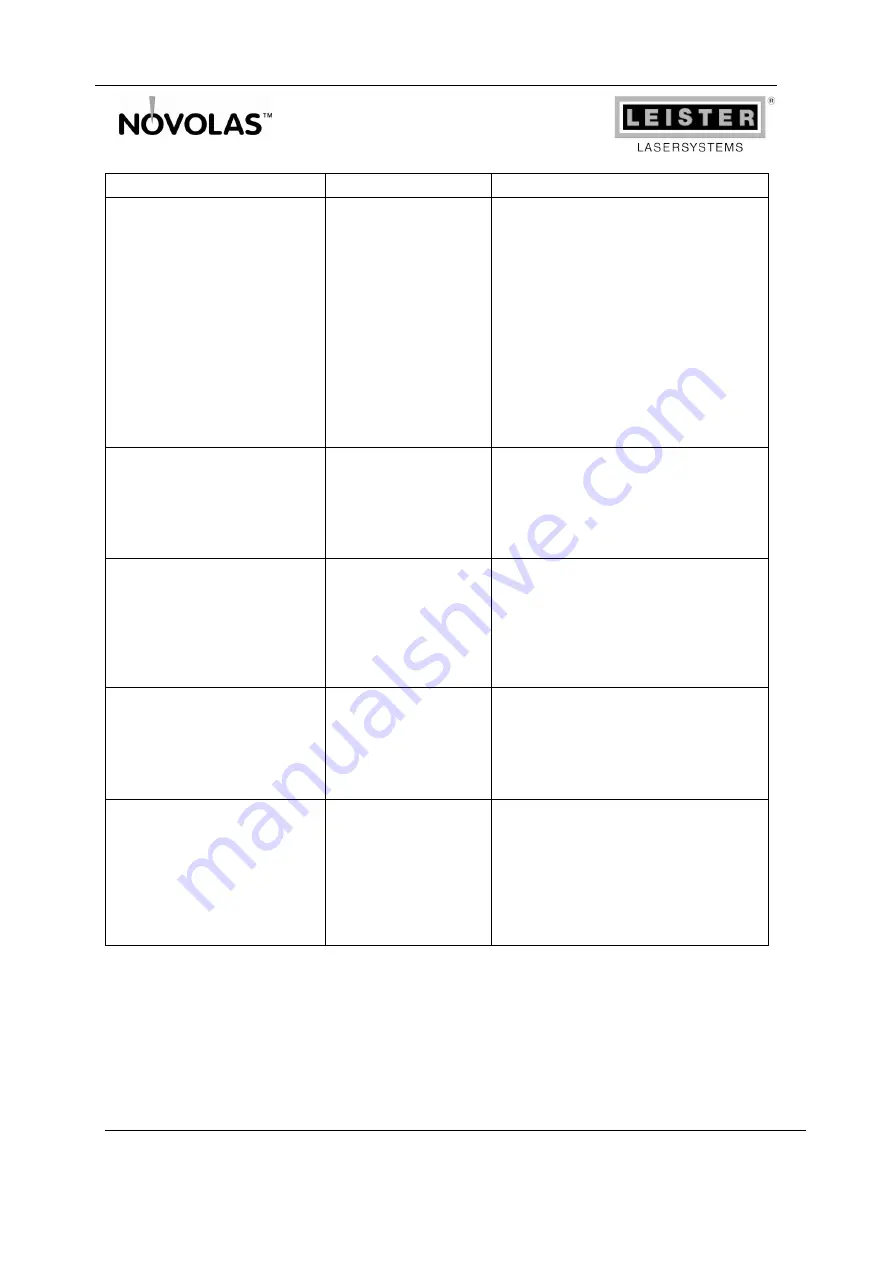

Service and Troubleshooting

Error

Cause

Action

Cooler: Conductance Error

Water conductance

value to low or to high

The conductance must be closely

controlled for some laser modules.

Leave the cooler running for few

minutes and control the conductance

value. Klick the Roll Info button, until the

conductance value appears in “µS“.

If it decreases, wait for disappearing of

the error and then power down and up

the system.

If the failure persists, exchange the DI

cartridge. For instructions see Module

Manual Cooler AT.

Cooler: Water level

To few cooling liquid

Check cooling system for tightness, if

water level errors are more frequent

than every 3 months.

Refill pure DI water. For instructions see

Module Manual Cooler AT.

Cooler: Water flow

To low water flow rate

Check cooling circuit.

Replace water filter cartridge.

If this error occurs more frequently than

every 6 months, please contact Leister

service personal.

System does not start up

(“System error or not ready

signal” of Customer I/O always

active)

Power supply.

System Master defect.

Ethernet connections

missing.

Assure and control power supplies.

Check all RJ45 Ethernet connectors.

Check that green LED of the RJ45

connectors are on.

System does not start up from

initialization state

(“System error or not ready

signal” of Customer I/O is inactive

but ^”Laser Unit #X error or not

ready signal” is active)

Precondition for system

activation not met

Check cooling circuit and free air flow.

Check direction of cooling liquid flow.

Check cooling liquid temperature

(standard 20°C)

Check water flow rate.