23

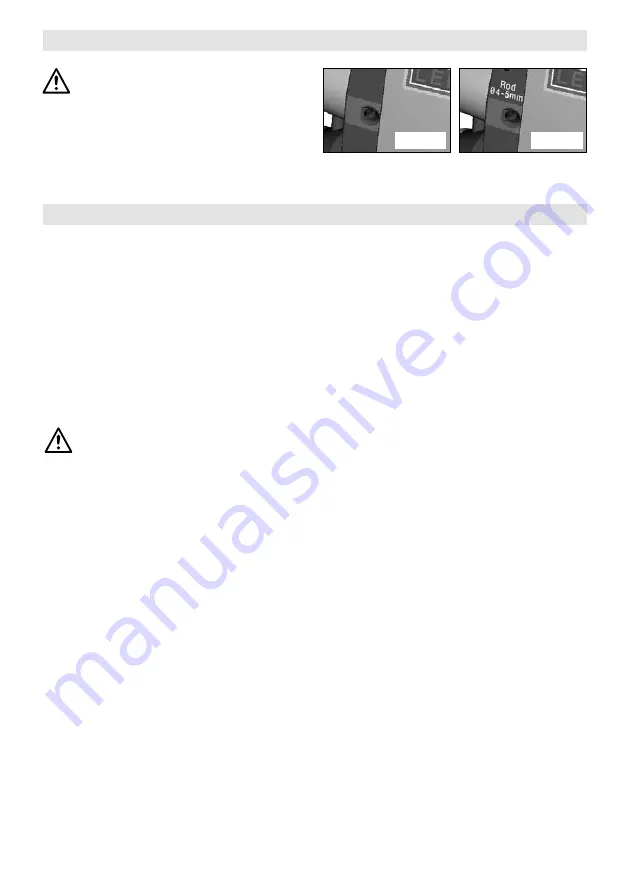

Welding rod, PE / PP Ø 3 or Ø 4 mm

– Only use for the hand extruder without

labeling

(see picture A)

.

Welding rod, PE / PP Ø 4 or Ø 5 mm

– Only use for the hand extruder with

labeling

(see picture B)

.

Welding rod

• Fit the required

welding shoe (8)

according to the paragraph „Changing the welding shoe” (see page 27).

• Connect the hand extruder to the mains supply.

• Switch on the tool at the

main switch (1)

.

• Set the

potentiometer (3)

to max.

• Once the operating temperature is reached («READY*» status), welding can begin.

• Activate the

motor on/off switch (2)

.

• Feed welding rod into the

welding rod opening (12)

(see chapter welding rod) and allow a small amount

plastizised material to escape.

• The welding rod is automatically drawn in through the

welding rod opening (12)

. The rod should feed in without

resistance.

CAUTION ! Never insert into both welding rod openings simultaneously. Never operate the tool

without welding rod.

• Interrupt the passage of plastizised material with the

motor on/off switch (2)

.

• Direct the

pre-heating nozzle (9)

towards the welding zone.

• Preheat the welding zone with a fanning motion.

• Place the tool over the prepared welding zone and reactivate the

motor on/off switch (2)

.

• Carry out a test weld according to the welding instruction of the material manufacturer and national standards or

guidelines.

• Check the test weld.

• Adjust the temperature setting and welding output as required (Seite 22).

• For a prolonged welding process, the

motor on/off switch (2)

can be kept in continuous operation by means of

the

locking device (4)

.

Starting the welding process

Picture A

Picture B

Summary of Contents for WELDPLAST S4

Page 59: ......