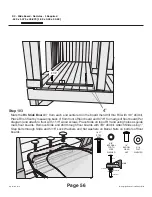

Page 52

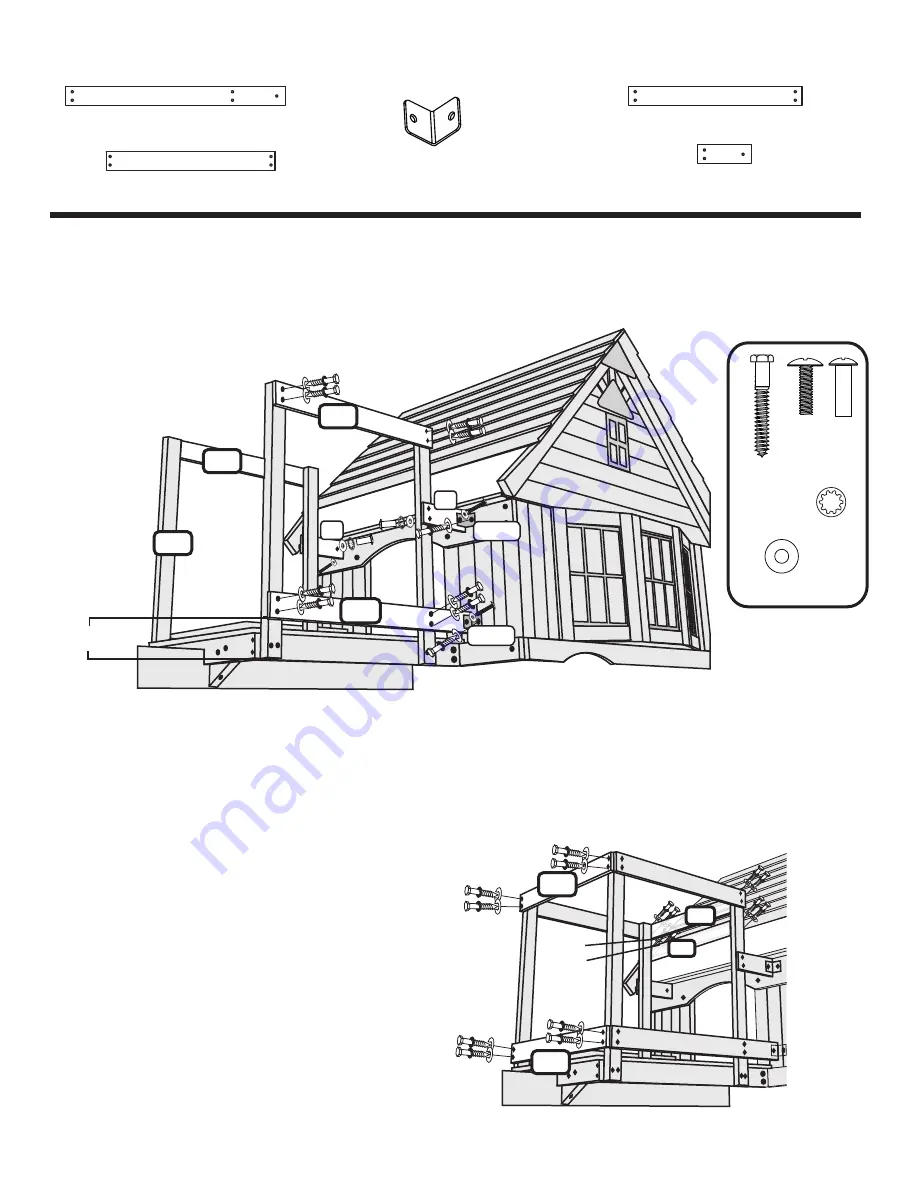

Step 93

Step 94

Step 95

Measure up 5” from bottom of F1 Supports and mark. Attach

P14 Crow's Nest Wall Rail

with 5/16” X 1 ½”

Lag Screws, Lock Washers, and Flat Washers. (Per Diagram). Now flush

P20 Crow's Nest Wall Rail

with top and edge of F1 Supports and attach with 5/16” X 1 ½” Lag Screws, Lock Washers, and Flat

Washers.

Attach

P31 Crow's Nest Wall Rail

to F1 Supports with 5/16” X 1 ½” Lag Screws, Lock Washers, and Flat

Washers (per diagram). Push P31 up against P8 Soffit Cap. Attach Y30-40Gs to P14 and P31 with ¾”

Phillips Truss Head bolt, 5/16” Lock Washer and 5/16” Flat Washer with a 5/16” Flat Washer on Barrel Nut.

Use Y30-40G at P14 to drill 3/8” hole through Wall Board and secure with ¾” Phillips Truss Head bolt, Flat

Washer, and 5/16” Lock Washer and Barrel Nut. Attach P31 to Clubhouse with 5/16” X 1 ½” Lag Screws,

Lock Washers, and Flat Washers through Y30-40G.

Note: Repeat Steps 93 and 94 on opposite side.

Attach two

P23 Crow's Nest Wall Rails

to F1

Supports flush at top and flush with P14 at

bottom with 5/16” X 1 ½” Lag Screws, Lock

Washers, and Flat Washers on outside of

Crow's Nest. Now attach P23 to F1 Supports

toward Clubhouse with 5/16” X 1 ½” Lag

Screws, Lock Washers, and Flat Washers.

Measure down 2 ½” per diagram and attach

another P23 to F1 Supports with 5/16” X 1 ½”

Lag Screws, Lock Washers, and Flat

Washers.

P14

F1

P20

P20

P31

P31

Y30-40G

Y30-40G

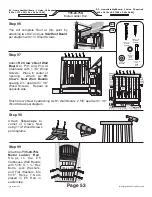

P23

P23

P23

P23

P14 - Crows Nest Wall Rail - 5 Holes - 2 Required

.625 x 3.375 x 38.75 [1.59 x 8.57 x 98.43]

P20 - Crows Nest Wall Rail - 4 Holes - 2 Required

.625 x 3.375 x 30.625 [1.59 x 8.57 x 77.79]

P23 - Crows Nest Wall Rail - 4 Holes - 4 Required

.625 x 3.375 x 29.75 [1.59 x 8.57 x 75.57]

P31 - Crows Nest Wall Rail - 3 Holes - 2 Required

.625 x 3.375 x 9.5 [1.59 x 8.57 x 24.13]

5”

2 1/2”

5/16 X 1 1/2"

LAG

SCREW

1/4 X 3/4"

PHILLIPS

TRUSS

HEAD

BOLT

1/4"

BARREL

HEAD

NUT

5/16"

INTERNAL

TOOTH

LOCK

WASHER

5/16" FLAT

WASHER

© Copyright Leisure Time Products Inc.

Sky Fort 09-0112

Y30-40G

2" x2" METAL

BRACKET

Note: Pilot drill with 3/16” bit.

Note: Pilot drill with 3/16” bit.