5.4006.8501.0

B

4-4

4.2.1.4

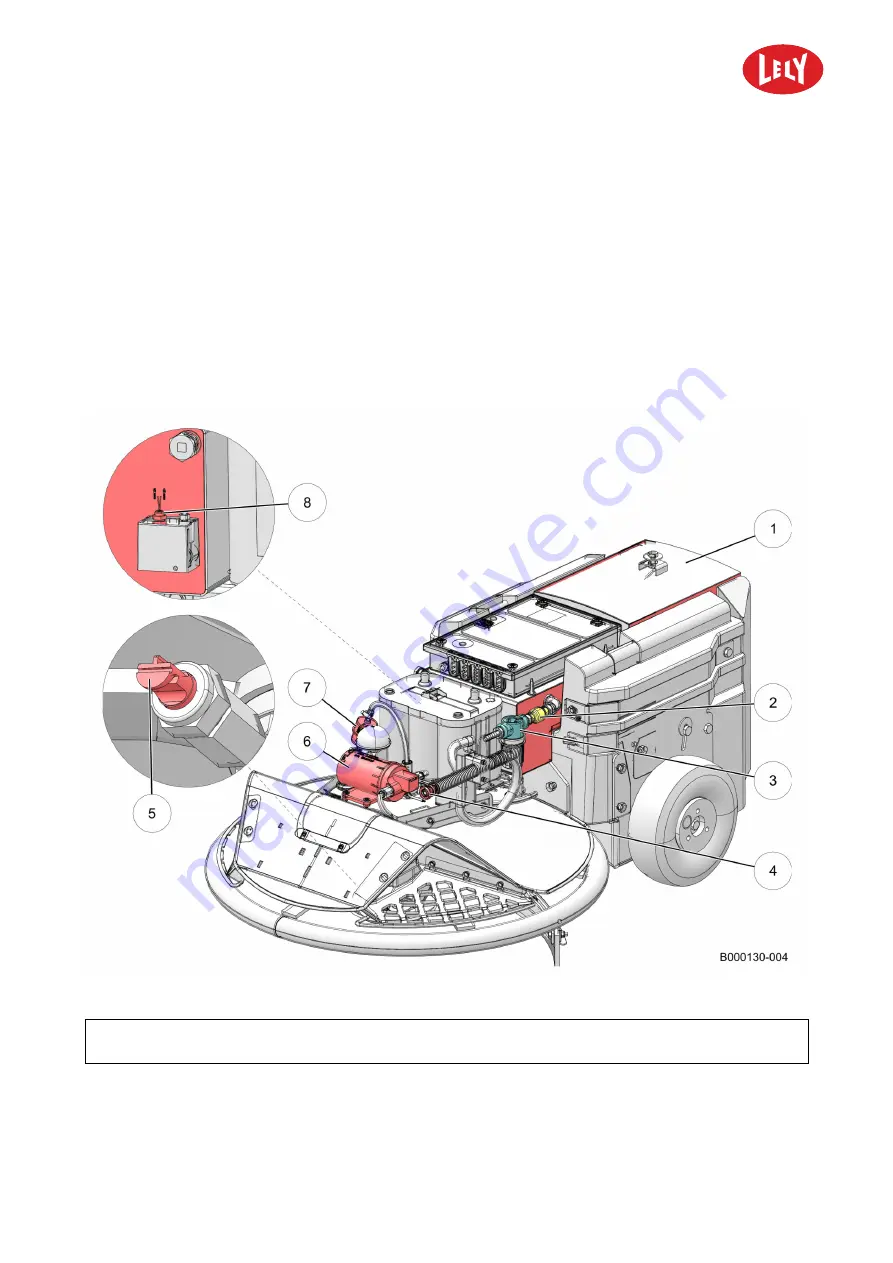

Water Supply System

The nozzle on the front sprays water on the manure to soften the manure. The water supply system has:

•

Water inlet.

•

Water filter.

•

Water tank.

•

Pump, pumps the water from the water tank to the nozzle. Switched on only during a route.

•

Nozzle.

The water tank is balanced installed on the concrete block and has a capacity of 30 liter, enough for one

route.

Figure 11. Water supply

KEY: 1. Water tank - 2. Non return valve - 3. Water filter (inlet) - 4. Water inlet - 5. Water spray nozzle - 6. Water pump - 7. Water

filter (outlet) - 8. Water sensor

in n o vato rs in ag ric u ltu re

Summary of Contents for Lely Discovery 90 SW

Page 2: ...INTENTIONALLY BLANK 5 4006 8501 0 B innovators in agriculture ...

Page 6: ...INTENTIONALLY BLANK 5 4006 8501 0 B 6 List of Included Amendments innovators in agriculture ...

Page 16: ...INTENTIONALLY BLANK 5 4006 8501 0 B 1 2 Lely Discovery innovators in agriculture ...

Page 62: ...INTENTIONALLY BLANK 5 4006 8501 0 B 4 36 Description and Operation innovators in agriculture ...

Page 98: ...INTENTIONALLY BLANK 5 4006 8501 0 B 5 36 Operating Instructions innovators in agriculture ...

Page 124: ...INTENTIONALLY BLANK 5 4006 8501 0 B 7 8 Test and Adjustment innovators in agriculture ...

Page 146: ...INTENTIONALLY BLANK 5 4006 8501 0 B 9 2 Disposal innovators in agriculture ...

Page 149: ......