18

2. Auxiliary handle (Fig.2)

Operate your power tool only with the auxiliary handle.

The auxiliary handle can be set to any position for a secure and low-fatigue working posture.

Turn the bottom part of the auxiliary handle in counterclockwise direction and swivel the auxiliary handle to the

desired position. Then retighten the bottom part of the auxiliary handle by turning in clockwise direction.

Pay attention that the band of the auxiliary handle is positioned on the front housing as intended for.

3. Install the Orientation Staff Gauge (Fig.2)

(1) Loosen the papilionaceous bolt on the auxiliary handle, and insert the staff gauge into the mounting hole on the

side handle.

(2) Adjust the staff gauge position according to the depth of the hole and tighten the papilionaceous bolt securely.

4. Regulating the number of rotations and hammering (Fig. 3)

This Rotary Hammer is equipped with a built-in electronic control circuit that can adjust and regulate the number

of rotations and times of hammering. This Rotary Hammer can be used by adjusting the speed adjuster knob,

depending upon the contents of operation, such as boring holes into fragile materials, chipping, centering, etc.

The scale ’1’ of the speed adjuster knob is designed for a minimum speed with the number of 235 rotations per

minute and 1350 times of blow per minute. The scale ‘6’ is designed for a maximum speed with the number of

514 rotations per minute and 2950 times of blow per minute.

CAUTION:

Do not adjust the speed adjuster knob during operation. Doing so can result in injury because the Rotary

Hammer must be held by only one hand, disabling the steady control of the Rotary Hammer.

5. Indicator LEDS (Fig. 4)

The green power-ON indicator LED lights up when the tool is plugged. If indicator led does not light up, the

mains cord or the controller may be detective. The red service indicator LED lights up when the carbon brushes

are worn out to indicate that the tool needs servicing.

OPERATION

CAUTION: To prevent accidents, make sure to turn the switch off and disconnect the plug from the receptacle

when the drill bits and other various parts are installed or removed. The power switch should also be turned off

during a work break and after work.

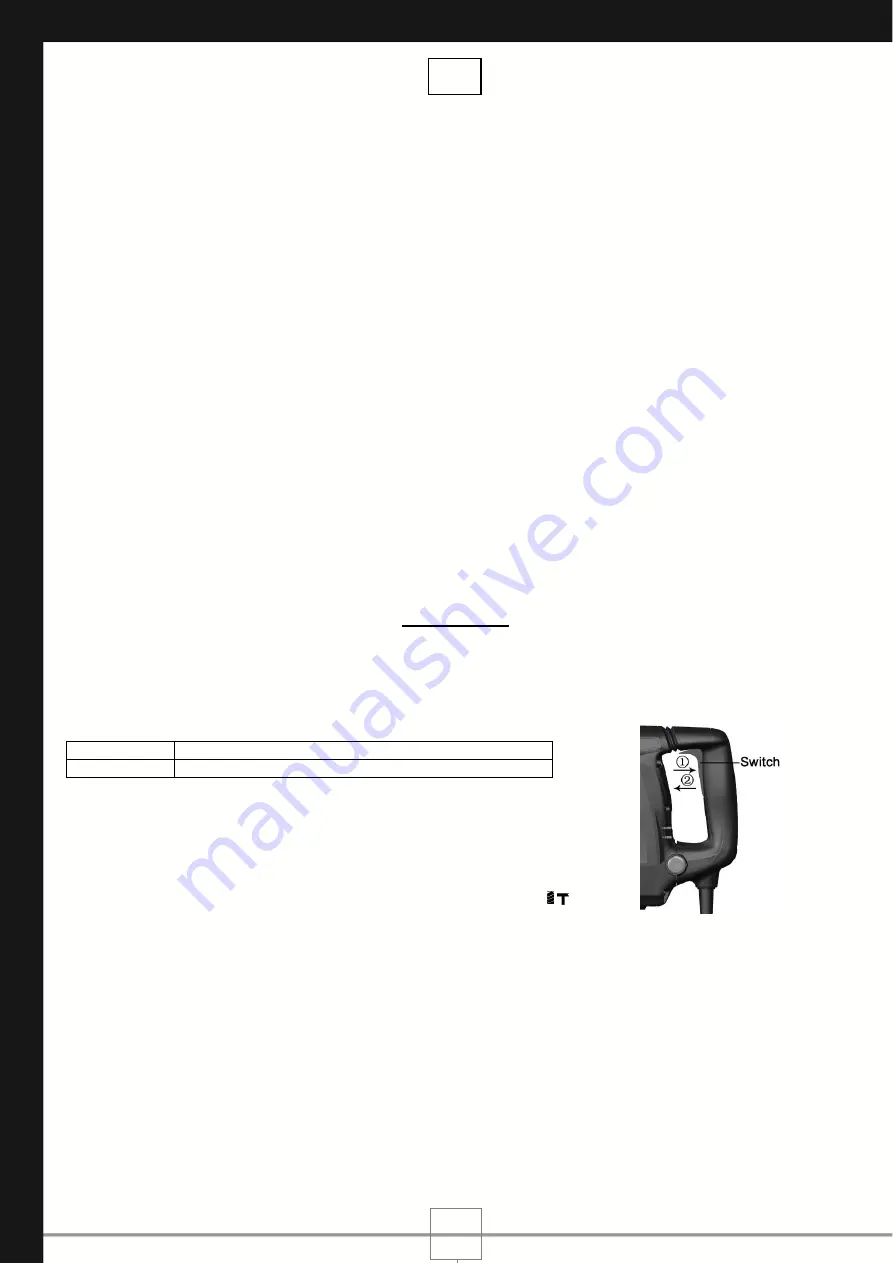

1. Switch operation

2. When drilling at “ro hammering”:

If you switch the function knob during motor rotation, the tool can start to rotate

abruptly, resulting in unexpected accidents. Be sure to switch the function knob

when the motor is at a complete stop.

(1) Switching to “ro hammering”

Turn the function knob clockwise. Align

▲

of the function knob and

of

the cover as illustrated in Fig.5.

(2) Mount the drill bit.

(3) Pull the trigger switch after applying the drill bit tip to the drilling position Fig.6

(4) Pushing the rotary hammer forcibly is not necessary at all. Pushing slightly so that drill dust comes out

gradually is sufficient.

CAUTION:

Although this machine is equipped with a safety clutch, if the drill bit becomes bound in concrete or other material,

the resultant stoppage of the drill bit could cause the machine body to turn in reaction. Ensure that the main handle

and side handle are gripped firmly during operation.

3. When chipping and chiseling at “hammering”:

CAUTION:

- If the function knob is switched during motor rotation, the tool can start to rotate abruptly, resulting in unexpected

accidents. Make sure to switch the function knob when the motor is at a complete stop.

Switch on

Press the switch towards (1) direction

Switch off

Release the switch towards (2) direction

GB

Summary of Contents for PSM040

Page 4: ...4 Fig 1 Fig 2 Fig 9 Fig 10 Fig 7 Fig 8 Fig 3 Fig 4 Fig 5 Fig 6...

Page 35: ...35 Figure A 2015 08...

Page 36: ...36 Notes...

Page 38: ...38 Notes...

Page 39: ...39 Notes...