11

STARTUP PROCEDURE

Whenever the pump is to be used, it must be pre-

pared for the type of paint to be used. This requires the

unit to be flushed out with an appropriate solvent (water

for latex, mineral spirits for oil base, etc.). Incorrect

flushing can cause gumming of the valves and priming

problems.

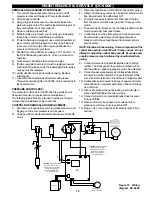

PRIME VALVE OPERATION:

1.

DC-3000: Valve turns continuously left or right.

PRIME position is when the valve is "pulled out" and

spray is when the valve is "seated in".

2.

DC-4000: Valve turns left or right. PRIME position is

when the valve is turned counterclockwise (pulled

out) ,and spray is when the valve is turned clockwise

(seated in).

UNIT PRIMING AND FLUSHING:

1) Check that all hose, gun handle and tip connections

are tight.

2) Place trigger lock in “LOCK” position. Plug unit into

correct power source.

3) Place prime valve into open or “PRIME” position.

4) Turn pressure control to minimum. Turn ON unit. On

the DC-4000 green indicator light should be on but

motor not running. If motor runs, re-check that pres-

sure control is turned to minimum.

5) Place suction into container of correct solvent.

Slowly, turn up the pressure control into the prime

zone. Motor will begin to run, watch for flow from

return tube.

6) Let pump prime for 20-30 seconds. Close prime

valve. Unit will build up a low pressure and cut out.

NOTE: Always turn down pressure control before

changing position of the prime valve. This reduces

shock loading of the pump and possible damage.

7) Turn zip tip to halfway position and remove from gun

(see page 9). Turn up pressure about 1/6 turn. This

gives a good low pressure for flushing and cleaning.

8) Aim gun into empty metal pail, holding gun body

against pail edge to ground gun for safety. Open

trigger, and allow solvent to flow for one minute.

9) Release and lock trigger (read static safety on page

4). Turn pressure control to minimum and open prime

valve to release pressure.

10) Unit is now flushed out.

PRIMING UNIT IN PAINT:

Follow same procedure as steps 1-7 of “Priming and

Flushing”, but instead using paint. Then continue with the

remaining steps as outlined below.

11) Remove tip from gun. Unlock trigger. Aim gun into

solvent pail and hold trigger open until solvent flow

changes to paint. Release and lock trigger. Re-install

tip.

12) Turn up pressure approximately 1/2 to 3/4 turn from

minimum setting.

13) This about 2000 psi, which is a normal spraying

pressure for many medium thickness products. As the

pressure you have set is reached, the motor will slow

down and cut out. DC-4000 only: as the hose contin-

ues to absorb pressure, it may cut momentarily in a

few times, to top up the line pressure. This is the

unique “kicker” feature which reduces “buzzing”

associated with most other units. This feature helps to

increase motor, brush and pressure control life.

14) The motor will run when the gun is open. Motor speed

(on the DC-4000), or motor on-off cycles (on the DC-

3000), is in relation to both the size of the tip, and the

pressure you have set.

Test spray pattern per chart below, and adjust pres-

sure accordingly.

Figure 8. - Spray pattern examples.

NOTE

TO TURN UNIT OFF:

Always reduce pressure, turn prime valve to prime, trigger

gun to release pressure build up in hose, and turn motor

off.

prime

valve

DC-4000

DC-3000

prime

valve