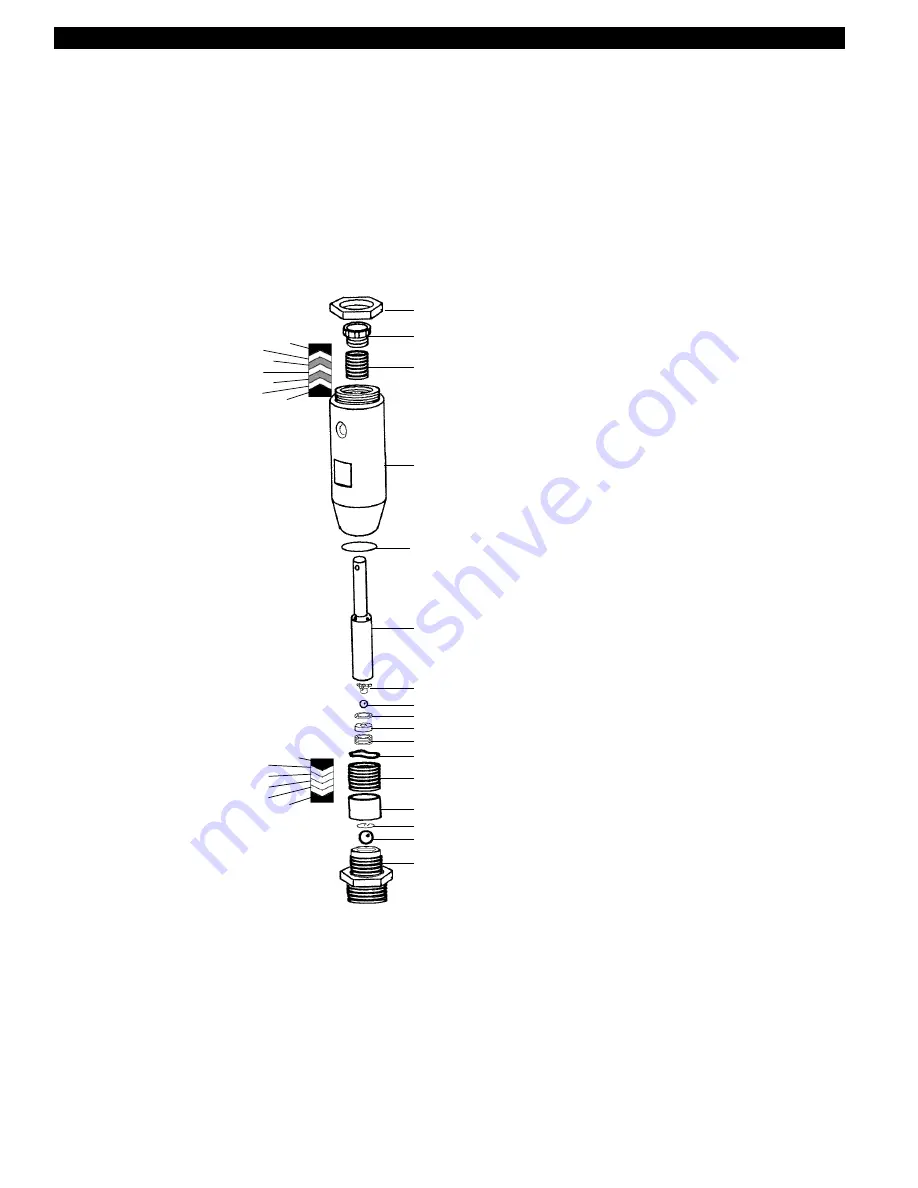

20

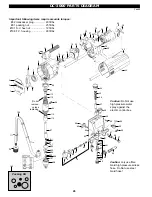

upper packings:

male support

poly

leather

poly

leather

poly

female support

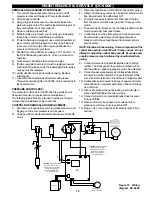

MAINTENANCE & SERVICE (DC-4000)

DC-4000 PACKING (L050-625 KIT) INSTRUCTIONS:

1.

Flush unit thorougly with appropriate solvent.

2.

Turn pressure control to minimum so that unit stops. Look

in opening of central body to observe position of connect-

ing screw.

3.

If necessary, turn control to prime and down again (briefly)

so that motor runs in short bursts. When motor stops with

connecting bolt at bottom of its travel, turn unit OFF.

4.

Relieve pressure via prime valve, and unplug unit from

electric outlet. Tilt unit back on handle and allow solvent to

drain.

5.

Using a 5mm allen key, remove pail hook.

6.

Using the same wrench, remove connecting screw from

plunger. (newer models

use a 4mm allen key).

7.

Disconnect fluid hose

from pump section.

8.

Using a pipe wrench,

and holding the

footvalve with another

wrench, remove

suction pipe and screw.

9.

Using a large crescent

or pipe wrench, loosen

locknut pos. # 1. Pump

will unscrew by hand.

10. Place pump assy in

vice, using flat areas on

cylinder, with footvalve

facing up.

DO NOT

OVERTIGHTEN!

Remove footvalve.

11. Place pump opposite

way in vice. Using

pliers etc, remove

packing nut pos. # 2.

12. While holding hand

under pump to catch

piston, gently tap on top

of piston pos. #6.

Packing spacer, pos. #

14 may also fall out at

this time.

13. Gently, using screw-

driver, pry out upper

packings and spacers

pos. # 3.

14. Remove pump cylinder

#4 from vice. Using fingers (or screwdriver and due care)

remove spacer, lower packings and wave washer pos. #

14, 13, 12.

15. Remove retaining clip pos. # 15, and ball pos. # 16 from

footvalve body. Ball seat is pressed into housing and is not

replacable.

16. Place wrench flats of tip of piston in vice, and using 10mm

allen wrench, take out shaft valve nut and seat pos.# 11,

10. Take piston from vice and remove shaft ball and

copper seal pos. 8, 9.

17. Thoroughly clean and dry all parts (except old packings).

18. Inspect upper and lower chrome areas of piston. Some

scratching is normal. If very extreme scratches or areas

missing hard chrome exist, the piston will have to be

replaced. A distinct darker, duller color in some areas may

indicate wear through the hard chrome.

19. Although new balls are supplied with kit, old ball condition

is a good indicator of seat wear. If the old balls are chewed

up or visibly smaller, take care to inspect shaft and

footvalve seats for wear.

20. Place new upper packings in oil (L034-125) to soak for 5-

10 minutes.

21. Put piston in vice using flats. Install new ball and copper

seal. Use a little bit of grease to hold seat in shaft valve nut.

Put one or two drops of blue or red locktite on threads.

Install by hand into shaft, then use wrench to tighten 40-45

ft/lb. Remove from vice.

22. Lightly grease inside of lower pump cylinder. Install wave

washer(s) and male packing spacer with flat end towards

washer. Lightly grease each packing and install with lips as

per diagram. Install female space V end first and push in

tightly by hand.

23. Turn pump cylinder over and lightly grease upper packing

bore. Install metal spacerflat end down. Install 1 x plastic

packing V end first, then in turn 1 x leather, 1 x plastic, 1 x

leather, 1 x plastic. Now put in thick plastic spacer V end

down. Lightly grease packing nut inside and on threads.

Install gently hand tight.

24. Lightly grease piston surfaces. Insert 10 mm allen wrench

for a holding tool, and push piston up through cylinder until

it stops.

25. Place pump cylinder open end up in vice. Install brass

spacer.

26. Lightly oil new footvalve ball, and place in body. Install

retaining clip. Lightly grease nose of valve and threads and

install approx. 20 ft./lb in pump cylinder.

27. Use teflon tape on threads of suction pipe. Hold footvalve

with wrench and install tube 10-15 ft/lbs.

28. Ensure large locknut pos. # 1 is bottomed out on threads.

Now grease threads of pump cylinder. Thread cylinder

assy. into central body until pin hole in top of piston just

lines up with pin hole in plunger.

29. Place one or two drops red or blue locktite on connecting

pin threads. Install pin and tighten 10 ft/lb.

30. Thread pump assembly onto unit until it bottoms out. Now

back pump up just enough that the paint outlet is in the

correct position. Securely tighten the locknut. (60-70 ft/lb)

31. Install paint hose to pump assembly, tighten 20 ft/lb. Place

a container of solvent under pump intake and set unit

upright.

32. Gently tighten packing nut until there is a slight resistance.

DO NOT OVERTIGHTEN OR PACKING/PISTON LIFE

WILL BE GREATLY REDUCED. Tighten just enough to

prevent leakage. Lubricate with L034-120/125 oil.

33. Prime and pressure unit checking for leaks.

DO NOT

TIGHTEN PACKINGS WITH UNIT RUNNING. FIN-

GERS OR TOOLS CAN BE TRAPPED BETWEEN

PACKING NUT AND PLUNGER, RISKING LOSS OF

fFINGER(S) OR SEVERE PERSONAL INJURY.

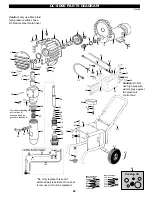

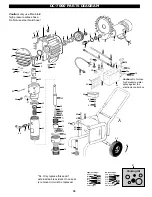

1

2

3

4

6

7

8

9

10

11

12

17

14

16

lower packings:

male support

teflon

teflon

teflon

teflon

female support

○

○

○

○

○

○

○

○

5

13

15