24

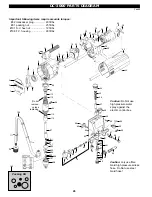

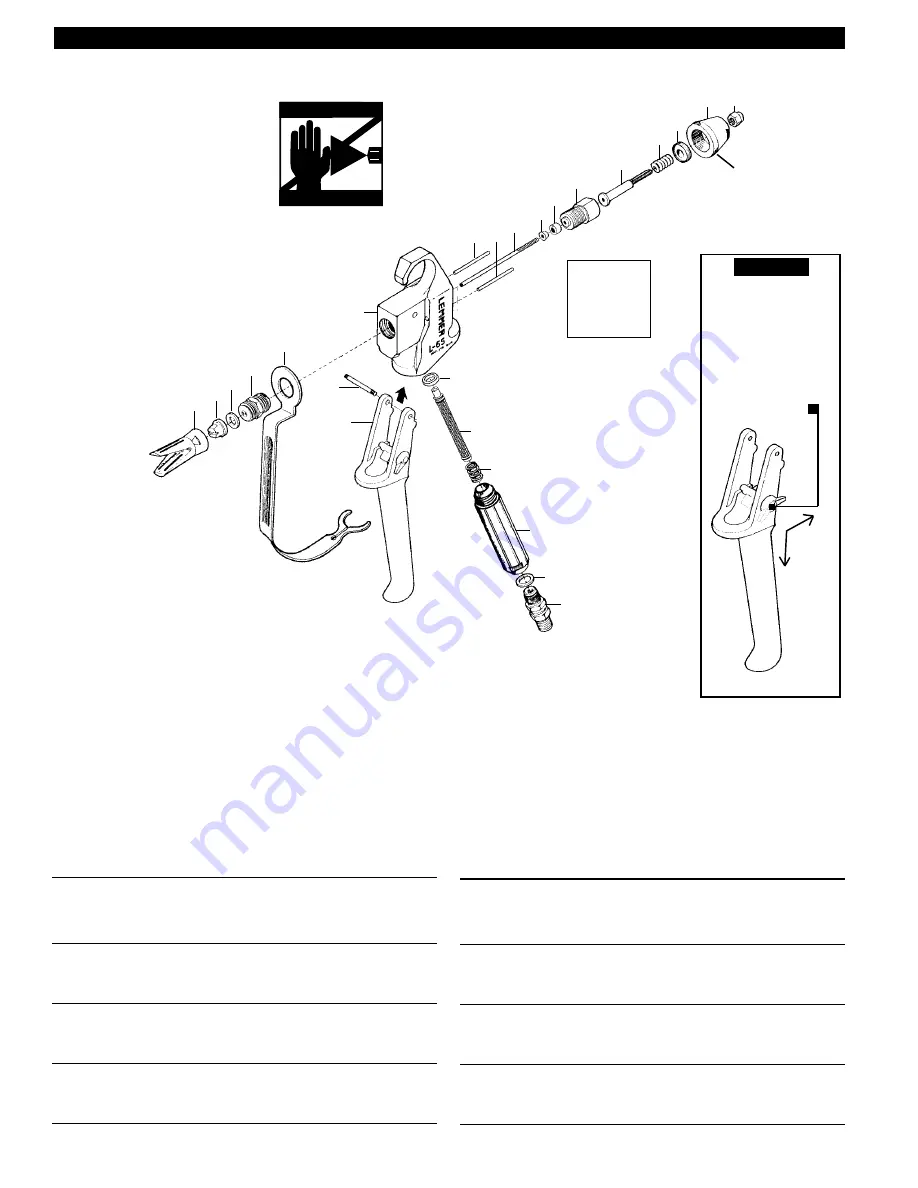

L-65 PARTS DIAGRAM & PARTS LIST

May00

Pos. Part nos.

Description

Qty.

L032-030 L-65 airless gun without tip nut

L032-035 L-65 airless gun without tip nut (G-thread)

1

L032-501 Tip retainer (11/16" L-thread)

opt.

L032-710 Tip retainer (7/8" G-thread)

opt.

2

tip (see separate list)

opt.

3

L043-008 Nylon washer

1

4

L032-711 Seat, (11/16" L-thread)

1

L032-712 Seat, (7/8" G-thread)

1

5

L032-589 Trigger guard

1

6

L032-523 Trigger pin

1

7

L032-713 Trigger complete

1

8

L032-714 Gun body

1

9

L032-591 Pin

2

10

L032-715 Ball with shaft

1

11

L032-507 Wedge

1

12

L032-508 Packing

1

13

L032-716 Housing

1

14

L032-582 Spring shaft

1

15

L032-588 Spring

1

16

L032-583 Housing nut

1

17

L032-587 Retainer cap

1

18

L032-590 Lock nut

1

19

L032-514 Handle seal

1

20

L032-516 Gun filter, white (50 mesh)

1

L032-517 Gun filter, yellow (100 mesh)

opt.

L032-518 Gun filter, red (200 mesh)

opt.

21

L032-519 Filter spring

1

22

L032-717 Handle

1

23

L032-520 Copper seal

1

24

L032-521 Swivel, 1/4" nps

1

Accessories:

L032-718 Repair kit, L-65-L (#4,10,12,14,18)

L032-719 Repair kit, L-65-G (#4,10,12,14,18)

Pos. Part nos. Description Qty.

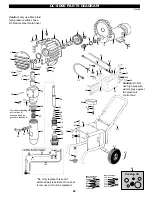

Turning this

nut tightens the

packing. Check

occationally and do

not over tighten.

HIGH PRESSURE!

INJECTION HAZARD!

Specifications, L-65

Maximum pressure: 3600 psi.

Tip thread: 11/16-16 or 7/8-14.

Hose connection: 1/4" nps.

Wetted parts: Al,SS,TC,Cu,

Brass,Tef.

Important

To engage trigger

safety lock, turn

lever tab to horizon-

tal position. Test

regularily for proper

functioning while

system is shut

down.

(trigger shown in horizontal

locked position)

locked

unlocked

• Remove filter for cleaning, then reinstall and hand tighten the handle.

• To clean gun: flush the inside by spraying proper solvent, and wipe the

exterior. (It is not neccessary to disassemble gun components under normal

circumstances).

• Follow shut down procedure before

servicing or cleaning equipment. (see #1

overleaf)

• This instruction sheet is only a supplement to

your system operating instructions. Read your

system manual before operating any high

pressure equipment.

Procedure, then follow the spray tip manufacturer’s instructions for removing and cleaning the

spray tip.

• Never attempt to change spray tip or leave the unit unattended without first shutting off

pump, releasing fluid pressure, and locking the trigger safety lock.

• Conductive metal containers must be used when flushing flammable fluids through

the system. Always flush at low pressure with spray tip removed. A metal part of the spray

gun must be held firmly against the grounded metal pail when flushing or relieving pressure

from the gun.

• Trigger guard helps reduce the risk of accidentally triggering the gun if dropped or bumped.

Do not use a spray gun without a trigger guard.

16

17

18

15

14*

13

12

19

11

24

23

22

21

6

7

8

5

4

3

2

9

1

10*

20

9

Important: this "double lip" end

of filter must go in the gun first.

o

• Injection hazard: Airless Painting Equipment can cause serious injury if the spray

penetrates the skin. Do not point the gun at anyone or any part of the body. The tip guard

provides some protection against accidental injection injuries, but is mostly a warning

device. Never put your hand, fingers or body over the spray tip. Gloves and clothing do not

necessarily offer any protection either. Keep the gun trigger safety lever in locked postion

when not spraying. Always have the tip guard in place while spraying.

In case of penetration seek medical aid immediately!

Note to physician: Injection

into skin is a serious traumatic injury. It is important to treat the injury surgically as

soon as possible. Do not delay treatment to research toxicity. Toxicity is a concern

with some exotic coatings injected into the bloodstream. Consultation with a plastic

surgeon or reconstructive hand surgeon may be advisable. Be prepared to tell the

doctor what fluid was injected.

• Do not use halogenated hydrocarbon solvents in this system; it contains aluminium

parts and may explode. Cleaning agents, coatings, paints, and adhesives may contain

halogenated hydrocarbon solvents. Don't take chances, consult your material supplier to be

sure. (ex: methylene chloride and 1,1,1 - Trichlorethane)

• Caution: When a flammable liquid is sprayed there may be danger of fire or explosion

especially in a closed area.

• Use extreme caution when cleaning spray tip guard. DO NOT try to wipe off build up

around the spray tip before following shut down procedure. Follow the Shut down

* note: once #10

& #14 are

assembled, the

length from end

to end must be

88 - 88.5 mm.