6

PUMP COMPONENTS

SPRAY GUN:

The spray gun is designed

specifically for airless spraying.

Since there is no compressed air

to atomize the paint, atomization

is accomplished by forcing the

paint at a very high pressure

(3200 psi) through a very small

hole (.017" diameter). Because

of this high pressure, the spray tip

and gun valve are made of

tungsten carbide for maximum

wear resistance. The gun body is

made of forged alloy and ano-

dized for chemical resistance.

As a safety feature, the spray gun

can be locked with the trigger

safety lever when you are not

spraying. Be sure to read all

warnings concerning the high

pressures of airless spraying on

page 3 & 4.

PISTON PUMP (DC-3000 & DC-4000):

Uses two sets of packings and two check valves in

conjunction with an abrasion resistant piston. This forms

a double acting pump; ie pumps on both up and down

stroke. Both sets of packings are stationary, eliminating

costly cylinder wear.

CENTRAL BODY (DC-4000):

Is a meeting point of pump and speed reducer. Helps

turn rotating motion of motor and reduce into an even up

and down motion to drive pump.

SPEED REDUCER(DC-3000):

Consists of a two stage gear reduction in permanent

grease for long life. All bearings are alsopermanently

greased. Converts the high speed output of motor into

very high torque to drive pump.

SPEED REDUCER (DC-4000):

Consists of a single stage gear reduction in an oil bath for

long life. All major bearings are also lubricated by this oil.

Converts the high speed output of motor into very high

torque to drive pump.

MOTOR (DC-3000):

Is an industrial grade high speed unit. Its permanent

magnet DC type construction withstands construction site

power fluctuations. The higher rpm of this motor results in

a compact and lightweight design.

MOTOR (DC-4000):

Is an industrial grade high quality unit. Due to the perma-

nent magnet DC type construction, the motor will run at

different speeds, depending on how much voltage it is

sent by pressure control box. This allows for highly

accurate control of pressure.

Motor also features long life brushes, which are readily

accessible from the outside.

PRESSURE CONTROL BOX (DC-3000):

A rugged membrane transducer transmits a paint pres-

sure signal to an electronic relay which then powers the

motor. This on-off design has a pressure fluctuation of

about 200 psi.

PRESSURE CONTROL BOX (DC-4000):

It balances input from the pressure control box with a

signal from the sensor. On the basis of these two inputs,

and electronic decision is made regarding how much

voltage, if any, is required by the motor to maintain an

even pressure. The more pressure set by operator, or

pressure drop from a large tip, the more voltage is sent to

motor to speed up the pump. When the gun is released,

the pressure rises and the motor is turned off.

The advantages of this system will become most obvious

if you try smaller tips (.011/.013) at lower pressures for

lacquering or other fine work.

A safety circuit is also incorporated which will turn the

pump off if it runs out of paint at spraying pressures.

(above approx. 1000 psi) If the unit drops from spraying

pressure to below approx. 500 psi, for more than 25

seconds continuously the safety will turn the pump off.

This is to reduce the typical packing damage from “dry”

running. At pressures below approx. 1000 psi, the safety

will not engage, making the unit fully compatible with all

types of pressure rollers. It also prevents interference of

the safety with typical cleaning procedures.

(trigger shown in horizontal

locked position)

locked

unlocked

Important

To engage trigger

safety lock, turn

lever tab to horizon-

tal position. Test

regularily for proper

functioning while

system is shut

down.

For models

L45 & L-50

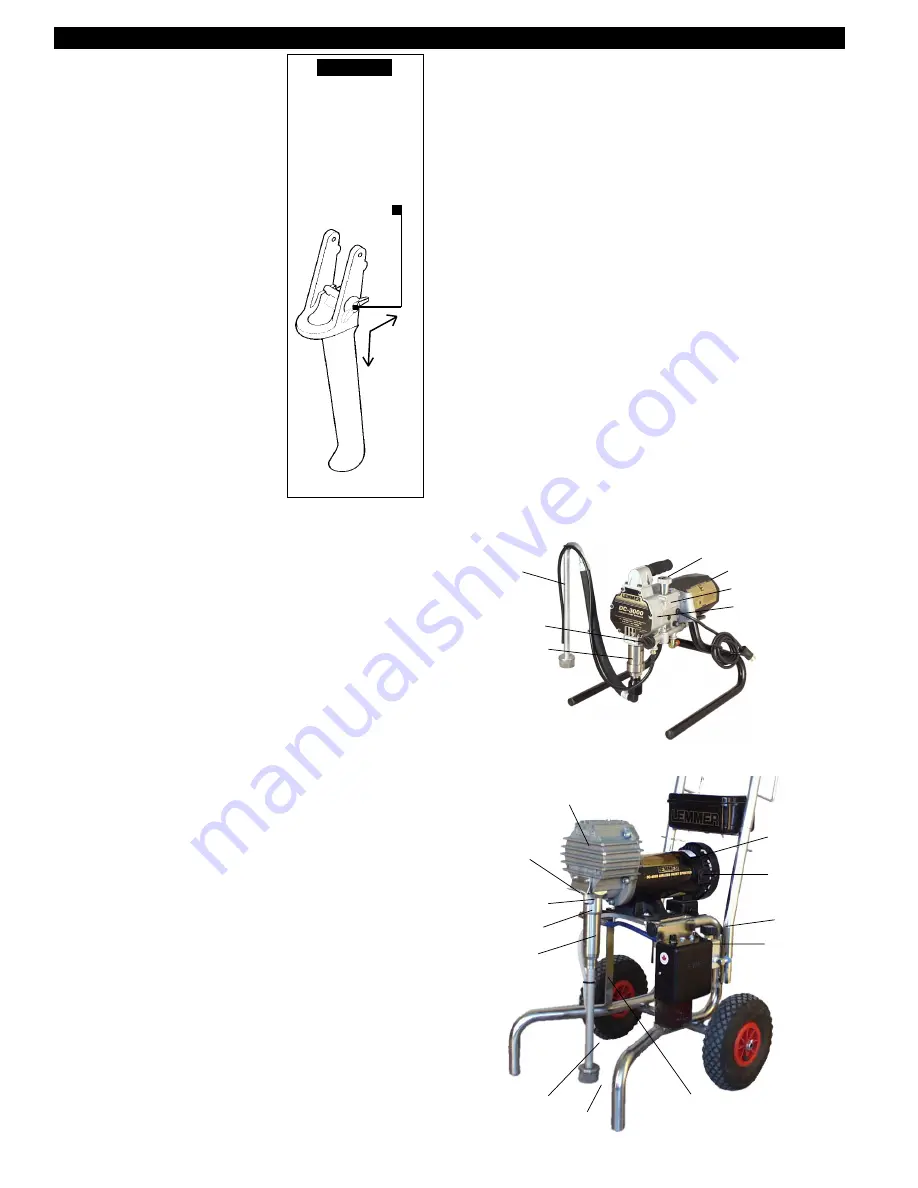

Figure 1b. - DC-4000 components.

motor

pail hook

suction pipe

return hose

control box

speed reducer

grease fitting

central body

paint pump

brush cap

suction screen

Figure 1a. - DC-3000 components.

paint pump

prime valve

motor

pressure control

control box

speed reducer

prime valve

suction

system