7

SETTING UP OF UNIT

TOOLS NEEDED:

2 x 8" or larger crescent wrench

PROCEDURE:

1) Remove all system components from the box for

assembly.

2) Remove protective cap from outlet connection of

pump.

3) Install handle and tool box. (DC-4000 only).

4) Connect high pressure airless paint hose to pump

outlet. Tighten to approximately 20 ft. lbs.

5) Attach the tip assembly to the spray gun.

6) Connect the paint hose to the swivel connection of

the spray gun. Tighten 20 ft lbs. Ensure the gun

handle is securely hand tightened to the gun.

7) Double check all connections, the unit is now ready.

Note: The pump contains a preservative oil when you

receive it, that may drip from the various connections

when the protective caps are removed.

WARNING: INJECTION HAZARD POSSIBLE. DO NOT

SPRAY WITHOUT TIP IN PLACE. ALWAYS ENGAGE

TRIGGER LOCK BEFORE REMOVING, REPLACING

OR CLEANING TIP. NEVER TRY TO CLEAN THE TIP

WITH YOUR FINGERS.

To disengage your trigger lock: Your spray gun is

shipped from the factory with the trigger lock in the

engaged position (horizontal on the L-65). To disen-

gage, turn the trigger lock down until it is in a vertical

position. To engage the trigger lock, turn it back to a

horizontal position.

trigger lock.

Figure 2. - L-65 gun components.

gun handle

with filter

inside.

hand tight

only!

tip.

tip housing.

trigger guard

for safety. do

not remove!

high pressure

swivel, 1/4"npt.

ELECTRONIC CONTROLS (DC-4000):

OFF: The first 10-20 degrees of pressure knob rotation

do not activate unit.

PRIME ZONE: The next approx. 20 degrees of rotation

will turn the motor on at a constant slow speed, when the

prime valve is in the open (prime) position. This is the

best speed for priming and cleaning the unit. It also works

well for power rolling. The safety cutout is not activated in

this zone. Maximum pressure in the prime zone is about

1000 psi.

SPRAYING ZONE: As the pressure knob is turned past

the prime zone (with prime valve open) the motor will

suddenly change from a constant low speed to full speed.

When the prime valve is closed, this will give fully adjust-

able pressure from about 900 psi to approximately 3000

psi.

The safety circuit is activated throughout the spray zone.

Safety turns motor off if the pressure drops from spraying

pressure to less than 500 psi for more than 25 seconds

(continuous). If the pump were to run out of paint, the gun

would have to be held open to ensure that the pressure

drop is enough to activate safety. This is to prevent

accidental triggering of safety with large tips, air bubbles

in paint etc. Indicator light will go off if safety has been

activated. Safety is re-set by turning power OFF for 3-5

seconds.

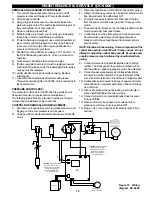

Figure 4. - DC-4000 control box components.

circuit

breaker

prime

valve

to prime,

turn ccw

on/off

pressure

control

"spray"

"prime"

"off"

sensor assembly

paint out (hose

connection)

indicator light

Figure 3. - DC-4000 system components.

foot valve

paint pump

oil drain

connecting bolt

packing nut

gear oil fill plug