8

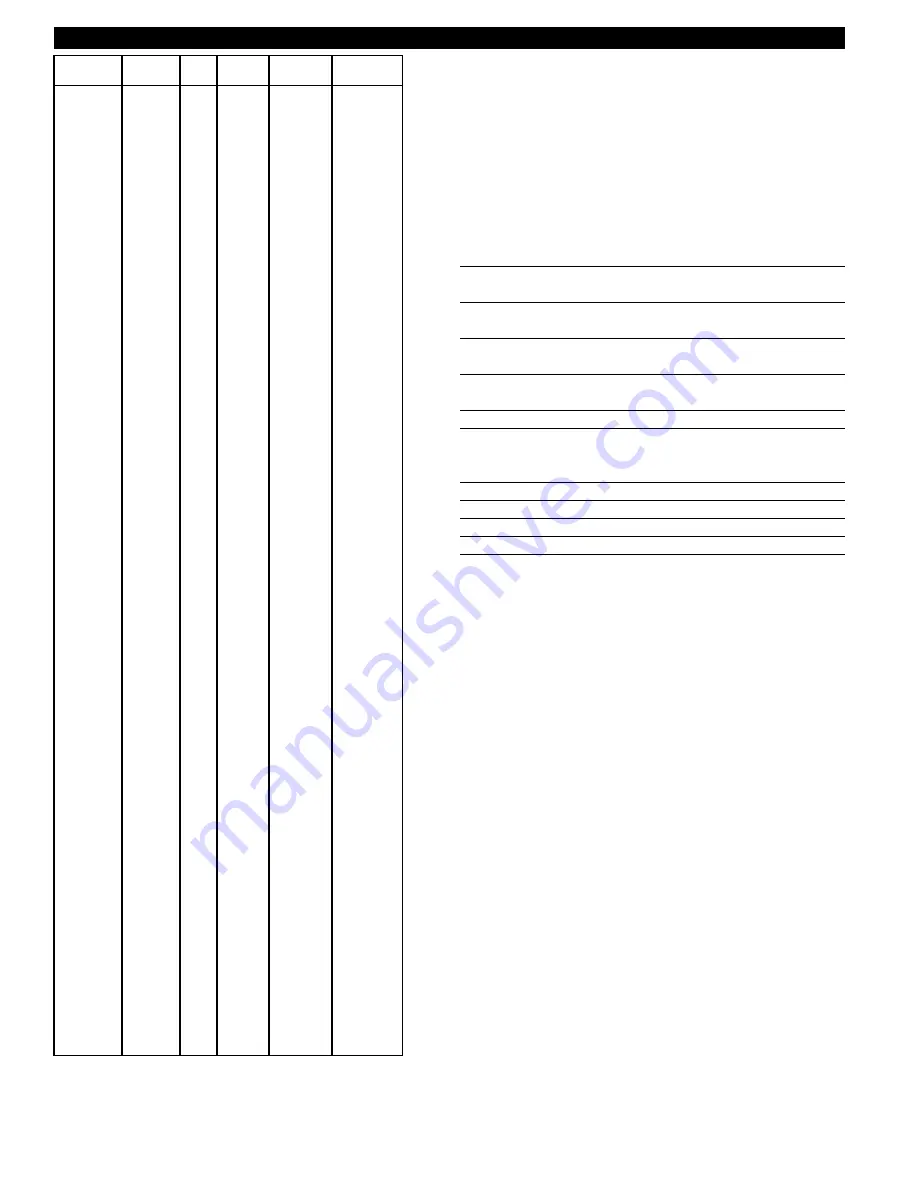

TIP SELECTION

FAN FAN FLOW TIP

PART NO. ORIFICE AT 1' ANGLE LTR/MIN MARKING

L043-091

.009

2"

10 DEG.

0.26

109

L043-092

.009

4"

20 DEG.

0.26

209

L043-093

.009

6"

30 DEG.

0.26

309

L043-094

.009

8"

40 DEG.

0.26

409

L043-095

.009

10"

50 DEG.

0.26

509

L043-096

.009

12"

60 DEG.

0.26

609

L043-111

.011

2"

10 DEG.

0.40

111

L043-112

.011

4"

20 DEG.

0.40

211

L043-113

.011

6"

30 DEG.

0.40

311

L043-114

.011

8"

40 DEG.

0.40

411

L043-115

.011

10"

50 DEG.

0.40

511

L043-116

.011

12"

60 DEG.

0.40

611

L043-117

.011

14"

70 DEG.

0.40

711

L043-131

.013

2"

10 DEG.

0.60

113

L043-132

.013

4"

20 DEG.

0.60

213

L043-133

.013

6"

30 DEG.

0.60

313

L043-134

.013

8"

40 DEG.

0.60

413

L043-135

.013

10"

50 DEG.

0.60

513

L043-136

.013

12"

60 DEG.

0.60

613

L043-137

.013

14"

70 DEG.

0.60

713

L043-138

.013

16"

80 DEG.

0.60

813

L043-151

.015

2"

10 DEG.

0.80

115

L043-152

.015

4"

20 DEG.

0.80

215

L043-153

.015

6"

30 DEG.

0.80

315

L043-154

.015

8"

40 DEG.

0.80

415

L043-155

.015

10"

50 DEG.

0.80

515

L043-156

.015

12"

60 DEG.

0.80

615

L043-157

.015

14"

70 DEG.

0.80

715

L043-171

.017

2"

10 DEG.

1.0

117

L043-172

.017

4"

20 DEG.

1.0

217

L043-173

.017

6"

30 DEG.

1.0

317

L043-174

.017

8"

40 DEG.

1.0

417

L043-175

.017

10"

50 DEG.

1.0

517

L043-176

.017

12"

60 DEG.

1.0

617

L043-177

.017

14"

70 DEG.

1.0

717

L043-178

.017

16"

80 DEG.

1.0

817

L043-192

.019

4"

20 DEG.

1.3

219

L043-193

.019

6"

30 DEG.

1.3

319

L043-194

.019

8"

40 DEG.

1.3

419

L043-195

.019

10"

50 DEG.

1.3

519

L043-196

.019

12"

60 DEG.

1.3

619

L043-197

.019

14"

70 DEG.

1.3

719

L043-198

.019

16"

80 DEG.

1.3

819

L043-213

.021

6"

30 DEG.

1.6

321

L043-214

.021

8"

40 DEG.

1.6

421

L043-215

.021

10"

50 DEG.

1.6

521

L043-216

.021

12"

60 DEG.

1.6

621

L043-217

.021

14"

70 DEG.

1.6

721

L043-218

.021

16"

80 DEG.

1.6

821

L043-219

.021

18"

90 DEG.

1.6

921

L043-234

.023

8"

40 DEG.

1.9

423

L043-235

.023

10"

50 DEG.

1.9

523

L043-236

.023

12"

60 DEG.

1.9

623

L043-237

.023

14"

70 DEG.

1.9

723

L043-238

.023

16"

80 DEG.

1.9

823

L043-239

.023

18"

90 DEG.

1.9

923

L043-254

.025

8"

40 DEG.

2.3

425

L043-255

.025

10"

50 DEG.

2.3

525

L043-256

.025

12"

60 DEG.

2.3

625

L043-257

.025

14"

70 DEG.

2.3

725

L043-258

.025

16"

80 DEG.

2.3

825

L043-259

.025

18"

90 DEG.

2.3

925

L043-274

.027

8"

40 DEG.

2.7

427

L043-275

.027

10"

50 DEG.

2.7

527

L043-276

.027

12"

60 DEG.

2.7

627

L043-277

.027

14"

70 DEG.

2.7

727

L043-278

.027

16"

80 DEG.

2.7

827

L043-279

.027

18"

90 DEG.

2.7

927

L043-294

.029

8"

40 DEG.

3.1

429

L043-295

.029

10"

50 DEG.

3.1

529

L043-296

.029

12"

60 DEG.

3.1

629

L043-297

.029

14"

70 DEG.

3.1

729

L043-298

.029

16"

80 DEG.

3.1

829

L043-299

.029

18"

90 DEG.

3.1

929

L043-313

.031

6"

30 DEG.

3.5

331

L043-314

.031

8"

40 DEG.

3.5

431

L043-315

.031

10"

50 DEG.

3.5

531

L043-316

.031

12"

60 DEG.

3.5

631

L043-317

.031

14"

70 DEG.

3.5

731

L043-318

.031

16"

80 DEG.

3.5

831

TIP SELECTION:

A standard size .017 tip will give good performance in

latex or oil base materials of moderate viscosities.

The following chart gives a basic idea of what tips the

Lemmer sprayers can handle performance wise and what

tip is appropriate for which material. Gun filter sizing is

also included in the chart for handy reference.

For a much more detailed look at tip sizes, please consult

the detailed tip chart on page 10.

Tip size Paint type

Filter size

.011

Lacquers, industrial enamel,

red

very thin paints.

.013

Oil stains, pigmented lacquers,

yellow

red oxide primer.

.015

Normal application of latex, oil base,

yellow

stains and , solid color oil stains.

.017

Fast application of latex paints

white

and stains, oil base paints.

.019

Heavier body latex paints.

white

.021

Fast application of heavier latex

white

paint, smooth block filter when

properly thinned.

.023

Maximum tip on DC-4000/L-1.

not req’d

.027

Maximum tip on L-5,000.

not req’d

.033

Maximum tip on L-7,500.

not req’d

.043

Maximum tip on L-10,000.

not req’d

The maximum tip for a pump is the largest tip that will

deliver a proper pressure for spraying without overwork-

ing or overloading. When a tip is used for some period of

time, it can wear beyond the maximum for the pump,

which will cause low pressure and poor spray pattern.

Stains and thick latex products often cause the most rapid

wear of the tip, while clear lacquers and varnishes cause

the least wear. Thus tip life can vary from as little as 50

gallons to as much as 200 or more, depending on the

product being sprayed and the pressure used.

Filters for the gun are picked not because of the type of

paint being used, but to protect a given size of tip. You

pick the tip for the type of paint and job being done and

then choose the filter to protect that tip. The chart on

page 10 gives much more detail about tip and filter

choices.

THE TWO MOST IMPORTANT THINGS TO REMEM-

BER ABOUT TIPS.....

1) Low pressure means longer life, for tips and the

pump. Less overspray too!

2) Worn tips waste paint and overwork the pump,

wearing it out quickly.