© 2020 Carrier. All Rights Reserved. LenelS2 is a part of Carrier.

2

DOC-6005-EN-US — revision 1.002

Tamper

1.

Connect tamper switch to appropriate inputs of control and indicating

equipment (CIE).

2.

Check that the tamper switch is CLOSED when the lid/cover is closed

and the retaining screw is fitted, OPEN when the retaining screw is

removed and the lid/cover is open. Use fine adjustment screw if

necessary, no more than one turn in either direction, to align indicator

with set point.

3.

Close the lid and fasten with screw supplied. Alternatively fit the

cover in place (the correct orientation is with the cover retaining

feature engaging over the bottom lip of the base) and fasten with the

supplied screws.

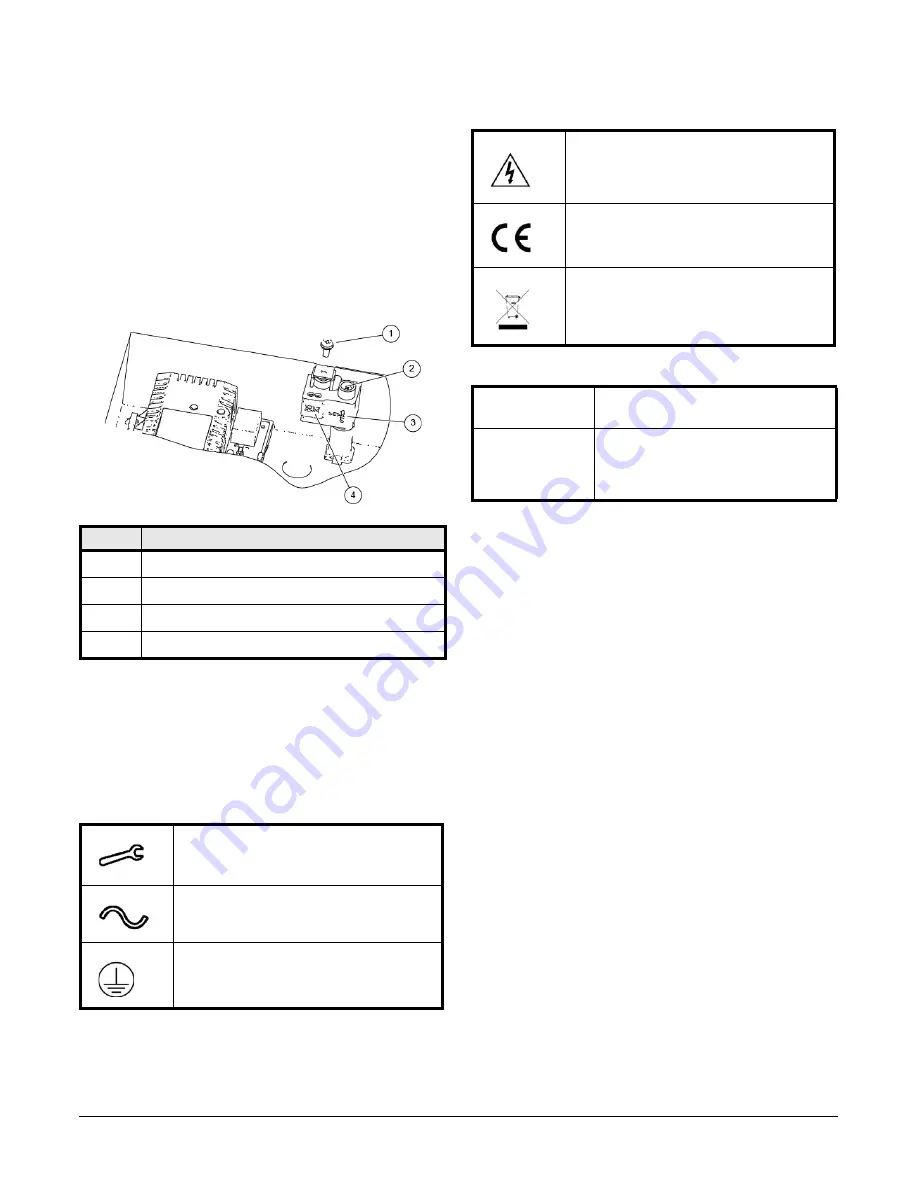

Tamper Arrangement

Operating Instructions

This unit is intended for use by Service Personnel only. There are NO USER

SERVICEABLE parts inside.

The green Mains LED is on while the mains supply is present. In the event

of a fault condition, the red Fault LED flashes and the corresponding (EPS

or GEN) fault signal contacts open.

Maintenance

Note:

Dispose of used batteries according to the battery manufacturer’s

instructions and all local and national regulations.

This unit is intended for use by Service Personnel only. There are NO USER

SERVICEABLE parts inside.

There is no regular maintenance required of the PSU other than periodic

testing, calibration check and replacement of the standby batteries.

Reference should be made to the battery manufacturer's documentation to

determine typical/expected battery life with a view to periodic replacement

of the battery.

Callout

Description

1

Retaining screw

2

Fine adjustment screw

3

Set position indicator

4

Tamper switch connections

Explanation of Symbols (not all may apply)

Fault Indication

Mains Present

Protective Earth

Shock Risk - Isolate before attempting access

Certification Level

Do not dispose of in unsorted waste

Local Indicators

MAINS LED

(Green)

Mains present

FAULT LED (Red)

Flashes (1s period) when: loss of mains,

battery disconnected, output fuse fail, battery

fuse fail, output short circuit or low output

voltage

Explanation of Symbols (not all may apply)