• 11 •

Installation, Operation and Maintenance Manual /

ARIA2-IOM-1910-E

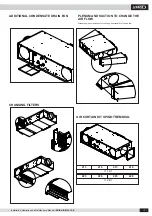

WATER COIL ROTATION

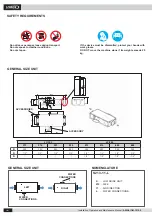

WARNING

Fans can reach a speed of 1000 r/min. Do not insert any object

nor hands. During operation, the engine warms up. Allow the

engine to cool before touching it. During the heating operation

the heat exchanger and the connecting pipes can reach high

temperatures (80°C). Wait until the cooling of the exchanger

before touching it or protect hands with suitable gloves. The

water heat exchange coils are suitable to operate in operation up

to the maximum pressure of 8 Bar.

For battery rotation, proceed as follows:

1. Unplug the power to the machine, if connected;

2. Make sure that the heat exchange parts have cooled down

completely, if the unit is installed and powered;

3. Drain any water present inside the heat exchanger, if the

unit is powered;

4. Remove the condensate trap bowl;

3. Remove the battery fi xing screws;

4. Remove the battery taking care not to cut the fi ns and not to

damage them;

5. Remove the knockouts from the opposite side of the unit

(using a screwdriver) to allow the passage of battery fi ttings;

6. Place the battery, turn it upside down without turning it so

that the joints protrude in correspondence of the knockouts

previously removed;

7. Secure the battery with the screws previously removed;

8. It is also recommended to reposition the terminal block

on the opposite side to that of the attacks. If during this

operation, it’s necessary to disconnect the terminal cables,

mark the cable locations to avoid making mistakes in the

process of reconnecting;

9. Replace the condensate drain pan.

CLEANING AND MAINTENANCE

WARNING

Before performing any cleaning or maintenance, disconnect

the device from the power grid!

ORDINARY MAINTENANCE

It is duty of the user to carry out all maintenance operations on

the unit. Only personnel previously trained and qualifi ed may

perform maintenance operations. If the unit must be dismantled,

protect your hands with work gloves.

Monthly checks:

- Make sure the vents are clean. Otherwise, clean them by

suction so as not to damage them.

-

Verify all electrical equipment and in particular the tightness

of the electrical connections

Annual checks:

- Check of all electrical equipment and in particular the

tightening of electrical connections.

-

Check the tightness of all the bolts, nuts and whatever else

can be loosened by the constant vibration of the unit.

- Check that the motor has no traces of dust, dirt and other

impurities. Periodically verify that it works without abnormal

vibrations or sounds, that the entrance to the fan is not

obstructed, resulting in a possible overheating of the

windings.

CLEANING THE AIR FILTER

The device is equipped with air fi lter in the fan inlet.

During normal operation the fi lter withholds impurities present

in the air.

It is necessary to periodically clean the fi lter to maintain the

fi ltration characteristics of the fan air.

You should clean the fi lter at least once a month as follows:

1. Remove the fi lter.

2. Place the fi lter on a fl at, dry surface, remove accumulated

dust with a vacuum cleaner.

3. Wash the fi lter with water and detergent (not solvents).

4. Leave the fi lter to dry in a ventilated place.

5. Replace the fi lter only after ensuring they are perfectly dry.

NOTE: Clean the fi lter at the beginning and end of each

season, or consistent with the work done.

TROUBLESHOOTING

There is little or no output air

Possible cause:

Possible remedy:

incorrect setting of

speed on the control panel

choose the right speed

fi lter clogged

clean fi lter

Ostruction of airfl ow

on discharge or suction

remove the obstruction

The motor does not run? Check that ...

-

the power is on

-

switches or thermostats are in the operating position

-

there are no foreign objects blocking the rotation of the fan

There are no foreign objects blocking the rotation of the fan

- t

he fi lter and battery are clean

-

it is not incoming air in the hydraulic circuit from the special venting

valve

-

the system is correctly balanced

-

the boiler / chiller functions

DISMANTLING DEVICE

This appliance is designed to last for many years. In case of

dismantling, obtain the services of qualifi ed personnel so that the

work is carried out in complete safety.

Always remember that the fi rst operation to be carried out

before dismantling the unit is to unplug it permanently from the

mains. This machine is manufactured using recyclable materials

(copper, aluminum, brass, plastic) assembled by screws and

joints in order to facilitate the unit’s separation.

Contact a fi rm specializing in differentiated waste disposal; just

so you can be sure of proper recycling and contribute to the

environment.