• 3 •

Installation, Operation and Maintenance Manual /

ARIA2-IOM-1910-E

PREMISE

This installation and maintenance manual must always accompany

the air handling units, so that it can be consulted by the installer

or by the user when needed. Installation should be carried out in

compliance with local regulations in each country, according to the

instructions of the manufacturer or qualifi ed personnel specialized

in his profession. Incorrect installation of the unit may cause

damage to people, animals or things for which the manufacturer

cannot be held responsible. The unit’s installation and connection

to the electricity network must be performed by qualifi ed personnel.

Before any intervention is necessary to verify that the device is

disconnected from the power grid. Consult this instruction manual

before installation.

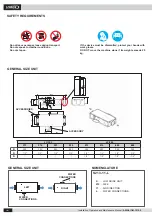

WARNINGS

The use of this device is easy, however it is important to read this

manual thoroughly before using it for the fi rst time. This way you

can:

-

Use the equipment safely;

-

Obtain best performance;

-

Ensure correct behavior;

-

Respect the enviroment.

- Do not allow children and unassisted disabled persons to

operate the appliance.

-

Do not touch the appliance when barefoot or with wet or damp

parts of the body.

- Do not pull, detach or twist any electrical cables, even when

disconnected from the power network.

- Do not open doors or panels providing access to the interior

of the unit without having fi rst put the system switch to “off.”

- Do not introduce pointed objects through the air intake grills

and air delivery.

- Do not dispose of, abandon or leave within reach of children

packaging materials (maps, staples, plastic bags, etc.) as it

can be dangerous.

-

Do not spray or pour water directly on the unit.

- Do not use the appliance in places with suspended dust,

or in potentially explosive atmospheres, in environments

with presence of oil in suspension, high humidity or in the

presence of particularly aggressive atmospheres.

- Do not cover the appliance with objects or drapes that even

partially obstruct the air fl ow.

The device operates with electric power to the mains voltage (230

V AC, 50Hz). Please keep in mind that mains voltage is potentially

dangerous and that any device connected to it must be used care-

fully. Before working on the appliance, unplug it from the mains

(pull the power plug or isolating the supply line by switching off the

main switch). If the unit is not used for long periods make sure that

the controls are in the O (off). Should the unit off during winter with

temperatures close to zero, empty the system and make sure that

the heat exchanger unit is completely free of water to avoid the risk

of ice formation and subsequent collapse. If the appliance must be

put permanently out of service, disconnect it permanently from the

mains. Any tampering or modifi cation will result in immediate ex-

clusion of warranty. In case of failure, never try to repair the unit by

yourself; seek advice from a qualifi ed technician. Repairs carried

out by inexperienced persons may cause damage or

accidents. Always keep the appliance clean, especially clean the

air fi lter periodically (at least once a month).

THE MANUFACTURER DECLINES ALL RESPONSIBILITY IF

THE INSTALLATION INSTRUCTIONS PROVIDED IN THIS

MANUAL ARE NOT OBSERVED. INCORRECT INSTALLATION

COULD LEAD TO POOR PERFORMANCE AND / OR FAILURE

OF THIS PRODUCT. IT COULD ALSO BE A SOURCE OF RISK

TO THE USER.

IDENTIFICATION DEVICE

The air handling units are equipped with an identifi cation plate that

reports:

- Address of the Manufacturer;

- Power supply voltage in "V";

- Marking "CE";

- Power supply frequency in “Hz”;

- Model;

- Number of phases indicated

with “Ph”;

- Batch number;

- Cooling capacity in “W”;

- Date of production;

- Sensible cooling capacity in “W”;

- Current consumption in "A";

- Thermal power.

- Power consumption in "W";

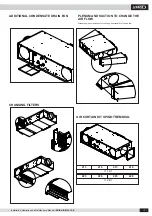

TRANSPORT, RECEIPT,

HANDLING

The packaging must remain intact until the time of installation. For

handling, depending on the weight, use appropriate means as

required by Directive 89/391 / EEC, as amended. Upon receipt

of the unit Please make an all-party control, in order to verify that

the transport did not cause damage. Any breakages present must

be communicated to the carrier, adding the saving clause on the

transport document, specifying the type of damage. For prolonged

storage keep the machines protected from dust and away from

sources of heat and vibration.

THE MANUFACTURER ACCEPTS NO RESPONSIBILITY FOR

DAMAGE DUE TO MISHANDLING, OR LACK OF PROTECTION

FROM WEATHER CONDITIONS.