• 8 •

OU

T

OU

T

IN

IN

H1

H2

Installation, Operation and Maintenance Manual /

ARIA2-IOM-1910-E

WATER CONNECTIONS

CONNECTION TO THE MAIN LINE

WARNING!

Always use a key and second key for connecting the

coil to the pipes. If the valve is present, adequately isolate the

valve body with insulating material.

Connect the inlet and outlet water pipes respecting what is

indicated on the side of the unit. Properly insulate the water

supply pipes to prevent dripping during cooling operation. On

the outlet tube must be inserted a shut-off valve and in the outlet

pipe a keeper. Also the valve body and holder must be properly

insulated to prevent dripping. Proper insulation should be

installed by the installer. The manufacturer assumes no liability

for the proper performance of the insulation.

NOTE: It is always advisable to install the valve. In the heating

mode, the valve reduces consumption because once it reaches

the temperature, the water circulation is blocked, avoiding thus

waste heat energy. In the cooling function of the valve, blocking

the water circulation when the temperature is reached, it prevents

the indoor heat exchanger continuing to condense water, with

the possibility of undesired dripping on the fl oor. It also reduces

chiller operation contributing to energy savings.

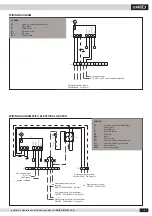

ELECTRICAL CONNECTIONS

WARNING

Before making the electrical connections, make sure that the

supply line is de-energized, making sure that the main switch is

in the OFF position:

- The electrical connections must be performed by qualifi ed

personnel.

-

Ensure that the network is single-phase 230 Vac/1/50 Hz (±

10%).

-

The unit exposed to voltages outside the above limits could

cause malfunction and will invalidate the warranty.

-

The supply line must be equipped with disconnect switch in

compliance with European standard EN60947-3.

- Make sure the electrical system is capable of providing

not only the working current required but also the current

needed to power other equipment already in use. Any

electrical and mechanical alterations or tampering will

invalidate the warranty.

The cables must be long enough, avoiding traction, which can

create bottlenecks or compressions of metal parts.

The power cables must have a length such that in case of

accidental traction of the conductors tend before the grounding

conductor. Connect the ground wire to the relative terminal

marked with the symbol . Check the connection of the grounding.

Observe the safety regulations in force in the installation country.

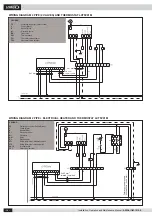

CONNECTIONS TO THE TERMINAL BLOCK

Electrical connections must be made on the terminal strip on the

side of the machine. The meaning of each terminal is indicated

on the label present on the terminal block.

WARNING: STRICTLY OBSERVE THE SPECIFIED

CONNECTIONS, FAILURE TO DO SO WILL CAUSE A BLOWN

ENGINE!

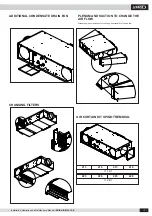

CONDENSATE WATER DRAINAGE

The condensate drain pipe must have a downward slope of at

least 3° and must not show upward strokes or bottlenecks to

allow smooth fl ow of water. It is appropriate that the condensate

drain is siphoned. The condensate drain should be connected to

a rainwater drainage system. Do not use the discharge of white

water or black to avoid possible aspirations of odors in the case

of the evaporation of water contained in the siphon. At the end

of work, check the smooth fl ow of condensate by pouring water

into the tray. The condensate water drainage system must be

installed in a workmanlike manner and should be subjected to

regular monitoring.

The manufacturer is not liable for any damage caused by

dripping in the absence of valve and periodic maintenance of

the drainage.

Siphon

H1=

p/10

H2=((

p/10)/2) + 30

p=

in Pa

H1; H2 = mm