18

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

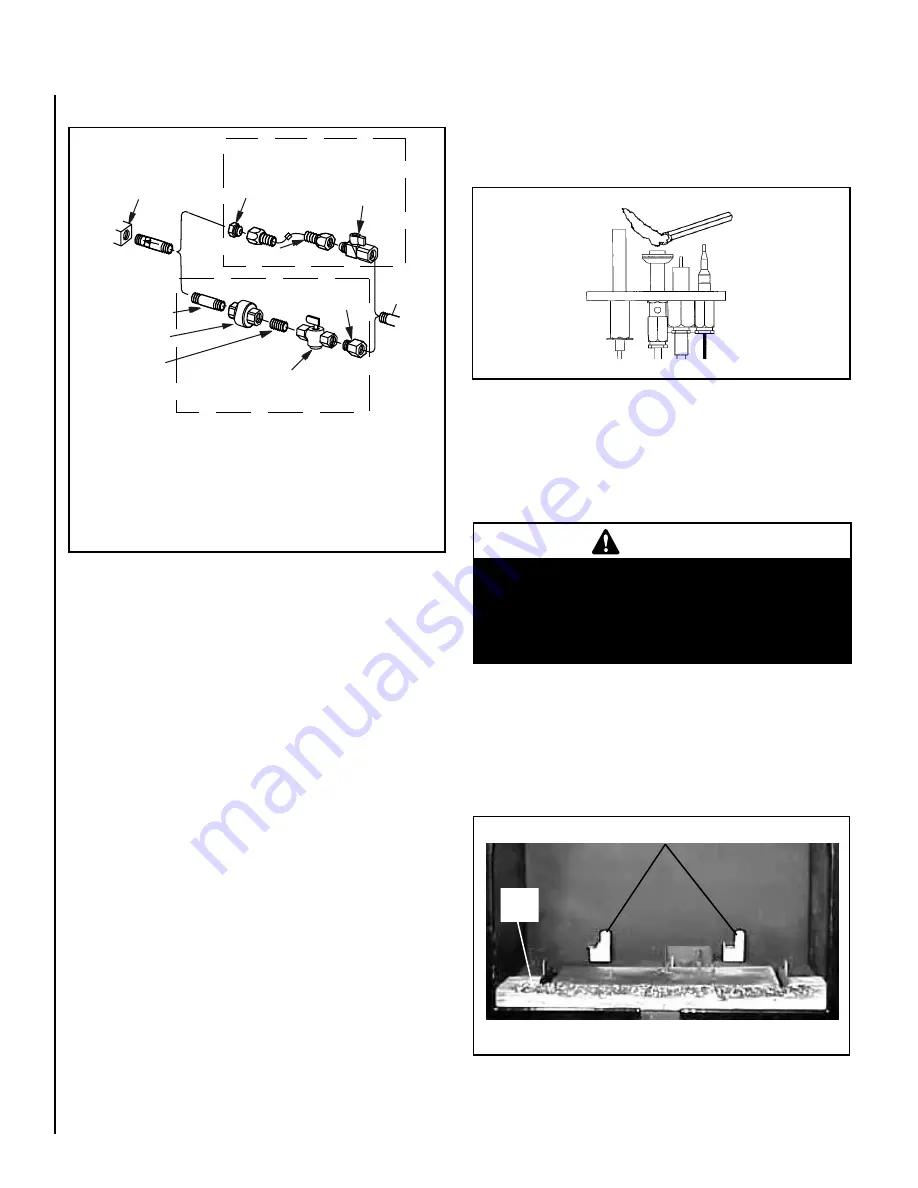

Gas

Valve

3/8" NPT x

Flare Fitting

3/8" Flex Tubing

3/8" Nipple

3/8" Union

3/8" Close

Nipple

3/8" Shut-off Valve

1/2" x 3/8"

Reducer

Gas

Stub

1/2" x 3/8" Flare

Shut-off Valve

Gas Solid Line Connector

Gas Flex Line Connector

*Sediment

Trap

3"

Min

Note: The gas supply line must be installed in accordance with building codes by

a qualified installer approved and/or licensed as required by the locality. In the

Commonwealth of Massachusetts, installation must be performed by a licensed

plumber or gas fitter.

*A Sediment Trap is recommended to prevent moisture and debris in gas line from

damaging the valve.

Make gas line connections. All codes require a shut-off valve mounted

in the supply line.

Figure 18

illustrates two methods for connecting

the gas supply. The flex-line method is acceptable in the U.S., however,

Canadian requirements vary depending on locality. Installation must be

in compliance with local codes.

These appliances are equipped with a gas flex line for use (where per-

mitted) in connecting the unit to the gas line. A gas flex line is provided

to aid in attaching the direct-vent appliance to the gas supply. The gas

flex line can only be used where local codes permit. See

Figure 18

for

flex line description. The flex line is rated for both natural and propane

gas. A manual shut off valve is also provided with the flex line. The gas

control valve is located in the lower control compartment. To access the

valve, open the lower access door. The millivolt control valve has a 3/8"

(10 mm) NPT thread inlet port fitting.

AIR PURGING PROCEDURES MUST PERFORMED BY A QUALIFIED

TECHNICIAN ONLY.

Purging Air from Supply Line

a. Turn gas supply line valve off.

b. Loosen setscrew at inlet pressure tap on upper right of control valve

(see

Figure 30

)

.

c. Turn gas supply line valve on.

d. When gas flows, turn supply valve off.

e. Close the inlet pressure tap.

Purging Air from Appliance

Purge air from appliance by holding gas control valve down in the pilot

position until pilot will light (see

Figure 19

).

DO NOT LIGHT A MATCH

IF YOU SMELL GAS.

Light a match then allow gas flow to pilot. If the

Match “blows”, there is air in the line (purge line). If the flame is straight

and tall, there is no gas pressure.

Step 10. CONNECTING GAS LINE

Figure 18 - G

AS CONNECTION

When first lighting the appliance, it will take a few minutes for the line

to purge air from the appliance. Once purging is complete, the pilot

and burner will light and operate as indicated in the instruction manual.

Subsequent lightings of the appliance will not require such purging. Inspect

the pilot flame (remove logs, if necessary, handling carefully).

Step 11. INSTALLING LOGS AND GLOWING EMBERS

The packaged log set and bag of glowing embers are located within

the firebox of the stove.

Installation Instructions:

Figure 20

Figure 19

Carefully install the ember strip and seven-piece log set into the

firebox as shown in these instructions. All logs should fit onto cor-

responding pins and/or log stoppers. This will ensure a proper flame

and safe combustion.

1.

Carefully place the ember strip as shown in

Figure 20

. Ensure

that it is pushed all the way back in position (toward the sub-floor

front flange).

WARNING

If logs are not installed according to the directions shown

here, flame impingement and improper combustion

could occur and result in soot and/or excessive produc-

tion of carbon monoxide (CO), a colorless, odorless,

toxic gas.

Ember

Strip

Rear Log Stoppers

Summary of Contents for CI1500DVF Series

Page 25: ...25 notes ...