9

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

12

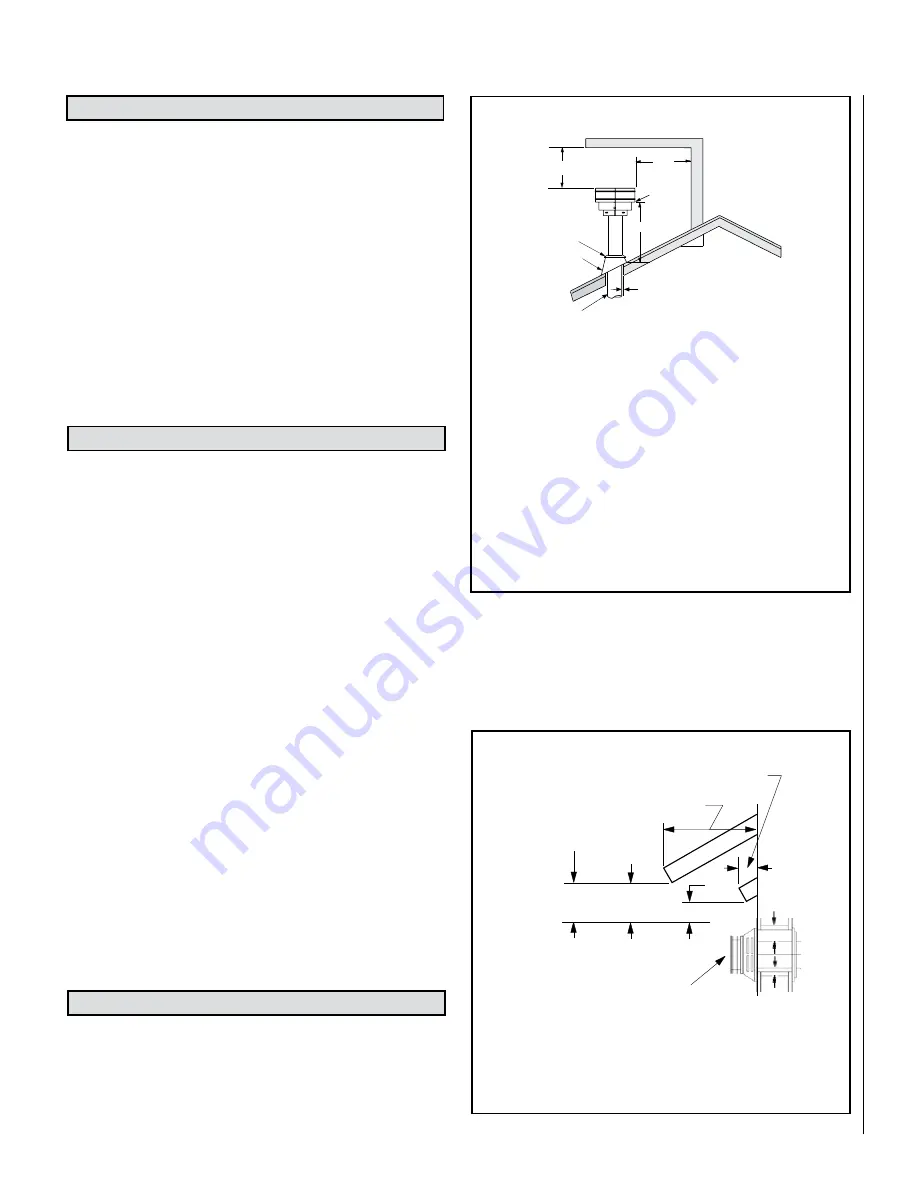

X

Roof Pitch is X/12

2 FT

MIN.

2 FT MIN.

Lowest

Discharge

Opening

H*

*H = MINIMUM HEIGHT FROM ROOF TO

LOWEST DISCHARGE OPENING OF VENT

TERMINATION HEIGHTS FOR VENTS ABOVE

FLAT OR SLOPED ROOFS

Horizontal Overhang

Vertical

Wall

Vent

Termination

Storm Collar

Concentric

Vent Pipe

Flashing

1 inch (25.4 mm) Minimum

Clearance to Combustibles

The vent/air intake termination clearances

above the high side of an angled roof is as

follows:

Roof Pitch.................. Feet

Meters

Flat to 6/12 ................ 1.0

0.3

6/12 to 7/12 ............... 1.25

0.38

7/12 to 8/12 ............... 1.5

0.46

8/12 to 9/12 ............... 2.0

0.61

9/12 to 10/12 ............. 2.5

0.76

10/12 to 11/12 ........... 3.25

0.99

11/12 to 12/12 ........... 4.0

1.22

12/12 to 14/12 ........... 5.0

1.52

14/12 to 16/12 ........... 6.0

1.83

16/12 to 18/12 ........... 7.0

2.13

18/12 to 20/12 ........... 7.5

2.29

21/12 to 21/12 ........... 8.0

2.44

Figure 4

Figure 3

Vertical Vent Termination Clearances

These instructions should be used as a guideline and do not supersede

local codes in any way. Install vent according to local codes, these

instructions, the current National Fuel Gas Code (ANSI-Z223.1) in the

USA or the current standards of CAN/CSA-B149.1 in Canada.

Horizontal Vent Termination Clearances

The horizontal vent termination must have a minimum of 3" (76 mm)

clearance to any overhead combustible projection of 2-1/2" (64 mm)

or less. See

Figure 4

. For projections exceeding 2-1/2" (64 mm), For

additional vent location restrictions refer to

Figure 5

.

Side Elevation View

3"

(76 mm)

12"

(305 mm)

Horizontal T

Combustible Projection

greater than 2 1/2 inches in length

Horizontal Vent Termination Clearances

Combustible Projection

2 1/2

inches or less in length

18"

(457 mm)

Ventilated

Soffit

Unventilated

Soffit

ermination Kit

3"

(76 mm)

1"

(25 mm)

Note - See vent manufacturer's instructions for recess

allowances, into exterior walls for the horizontal

termination caps.

MANUFACTURED (MOBILE) HOME REQUIREMENTS

QUESTIONS TO ASK LOCAL BUILDING OFFICIAL

VENT TERMINATION CLEARANCES

These models may be installed in an aftermarket permanently

located, manufactured home, where not prohibited by local codes.

When installed in Manufactured Housing the following supplemental

requirements must be met:

• The appliance must be secured to the floor (i.e. use (4) 1/4" x 2-3/4"

bolts and nuts or equivalent. Note: Not included) for securing appliance

to the manufactured home floor.

• The appliance must be grounded to the chassis of the manufactured

home. Use a No. 8 or heavier copper wire at least 18” in length.

• The structural integrity of the manufactured home floor, walls, ceiling

and roof must be maintained.

• A manufactured (mobile) home installation must conform with the

Manufactured Home Construction and Safety Standard, Title 24 CFR,

Part 3280, or, when such a stan-dard is not applicable, the Standard

for Manufactured Home Installations, ANSI / NCSBCS A225.1, or

standard for Gas equipped Recreational Vehicles and Mobile Housing,

CSA Z240.4.

This appliance must be installed per manufacturers’ instructions.

Installations must conform to appropriate local codes and applicable state

and federal requirements. Familiarity with these requirements before

installation is essential. Some important considerations to discuss with

local building officials include:

1. Applicable codes (i.e. Uniform Mechanical Code, State or Regional

Gas Codes, National Fuel Gas Code)

2. Local amendments

3. Recognized testing lab: OMNI-Test Laboratories Inc.; Beaverton,

Oregon

4. Is a permit required - cost?

5. In some states or municipalities, a licensed gas fitter or plumber may

be required to install this appliance. Check with your local building

official for requirements in your area (i.e. Is a license required for

installation of gas supply line)?

6. Maximum amount of gas pipe without a pressure test - type of test

required?

7. Are below grade penetrations of the gas line allowed?

8. Is concealed gas piping allowed?

9. Specific requirements of concealed fittings?

10. Is rigid pipe to appliance required?

11. Allowed piping materials?

12. Shut-off valve required within 4 feet of the firebox?

13. May the shut-off valve be concealed?

14. Rooms where the installation is not allowed?

In the absence of local codes, installation should conform to National

Fuel Gas Code, ANSI Z223.1 / NFPA 54-Latest Edition in the USA or

National Fuel Gas Code,

CAN/CSA-B149.1

-Latest Edition in Canada.

Summary of Contents for CI1500DVF Series

Page 25: ...25 notes ...