19

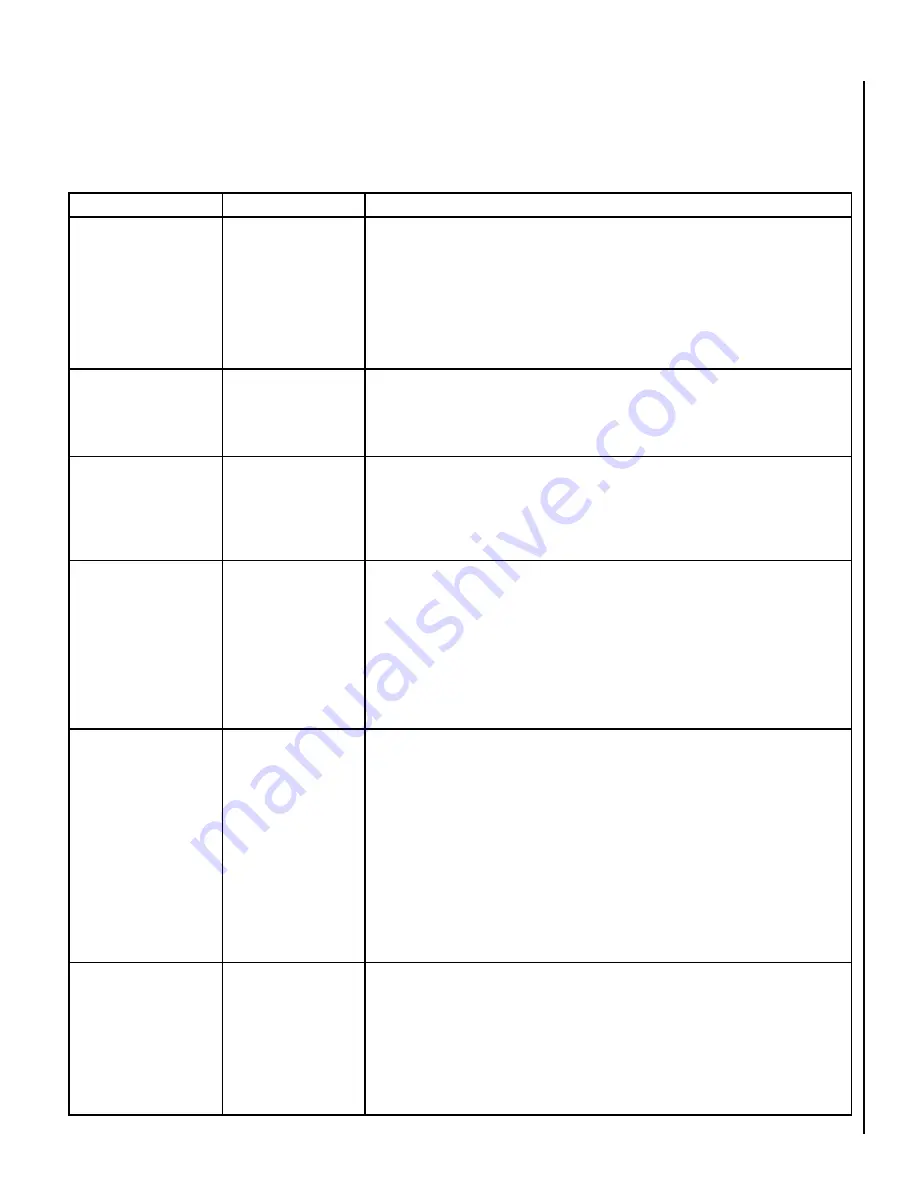

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

Thin black coating (soot)

forms on the viewing

glass, logs, or firebox

Improper log or ember

placement

Improper air shutter

setting

Not enough combus-

tion air

See

Log Set Installation on Page 10

. If there is soot in one specific location, the

rockwool below this location needs to be adjusted. This can be done by pulling embers

forward slightly. If the flames have soot tails, the shutter will need to be opened.

If sooting continues open air shutter (see

Air Shutter Adjustment on Pages 12 & 13

).

Check for debris obstructing air flow in valve compartment under insert or in front of

lower venting.

Humming or whistling

coming from insert.

Normal operating noise

Obstructed orifice

opening

See

Quiet Operation on Page 15

. The noise may be reduced by slightly turning down the

flame. Turning the flame down will reduce the heat output of the insert.

If noise is excessive or is “whistling” have your gas supplier check the regulator and

orifices and replace if necessary.

A change in flame appear-

ance or burner operation.

A change in gas pres-

sure

Improper ember place-

ment

Have your gas supplier check for correct gas pressure (7" W.C. / po. C.E. [1.74 kPa] natu-

ral gas; 11" W.C. / po. C.E. [2.74 kPa] LP gas).

NOTE: NEVER BLOCK OR OBSTRUCT AIR

INTAKE OR OUTLET VENTS.

See

Log Set Installation on Page 10.

Spark igniter will not light

pilot after repeated tries.

No gas supplied to unit

or air in line

Defective igniter (no

spark at electrode)

Defective or misaligned

electrode at pilot (spark

at electrode)

Check gas supply. To purge, hold in gas cock on valve for 1-2 minutes and try again.

Check for spark at electrode and pilot, if no spark and electrode wire is properly con-

nected, replace igniter and igniter wire.

Using a match, light pilot. If pilot lights, turn off pilot and trigger the igniter again. If pilot

lights, an intermittent gas/air supply may be the problem, if longer purge will not light

- check gap between electrode and pilot - should be 1/8 inch (3 mm) to have a strong

spark. If OK, replace pilot.

Pilot will not stay lit after

carefully following lighting

instructions.

Low gas inlet pressure

Defective thermopile

Defective automatic

valve operator

Check inlet pressure and adjust pilot if necessary.

Be sure wire connections from thermopile are tight at gas valve terminals.

Either rocker switch or thermostat wires may be grounded. Remove wires from valve

terminals. If pilot stays lit, trace switch wiring for a ground. May be grounded to insert or

gas supply.

Check open circuit millivolt output of thermopile. Reading should be greater than 325mV.

Also check thermopile wire for kinks that can cause loss of mV. Replace faulty thermopile

if wire is okay and reading is less than 325mV.

Turn valve knob to “ON” and thermostat (if installed) to 90º. Millivolt meter should read

greater than 100 mV. If reading is OK and burner does not turn on, replace gas valve

(qualified service technician only).

Main burner will not burn. Pilot has gone out

Rocker switch, thermo-

stat, or wires defective

Thermopile may not be

generating sufficient

millivolts

See

Lighting Instructions.

Disconnect rocker switch and thermostat wires at terminals 1 and 3 on valve. Jumper

across from 1 to 3 with pilot lit. If burner comes on either rocker switch, thermostat, or

wiring is not functioning.

Check thermopile with millivolt meter (see

Maintenance and Servicing

), recheck symp-

tom #2.

Troubleshooting

NOTE: When troubleshooting the gas control system, be sure the external gas shut off valve, located at the gas sup-

ply inlet is in the “ON” position.

IMPORTANT: Call your gas supplier or plumber for additional help with any gas control problem. Valve system

troubleshooting should only be accomplished by a qualified service technician.