9

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

v

ertiCal

v

enting

The vent pipes must be connected to the proper collars on

the unit and the exhaust vent pipe must be connected to the

termination cap or the unit will not operate. The combustion

air vent pipe can be connected to the termination cap or it

can terminate inside the chimney.

The bottom opening of the chimney must be sealed around

the vent pipes if the combustion air vent is not connected

to the termination cap. Use unfaced fiberglass insulation to

seal around the vent pipes. The insulation may give off an

odor during the first hour of operation.

NOTE:

The minimum vertical rise (exhaust vent) is 10 feet

(3.1 M) and the maximum vertical rise is 35 feet (10.7 M).

These dimensions are measured from the starting collars

of the unit to the end of the vent pipe.

The fireplace and fireplace chimney must be clean and in good

working order and constructed of non-combustible materials.

Inspect chimney cleanouts for proper fit and seal.

* Other approved vent components include; Standard Simpson Dura-vent Co-linear

Chimney Liner Kit, Direct Vent Termination #991, Liner Termination Kit (includes

termination connector and flashing) #923GK & 3" x 35' Alum Flex #2280

Vent Kits *

Cat. No.

Model

Description

H0909

FKDVI

Flex Liner Kit, DVI 3” X 35’

(requires 2, one for exhaust, and one for intake)

H0908

TKDVI

Termination Kit, DVI

(termination cap and flashing)

Installation

v

enting

i

nstallation

Your Lennox™ gas insert must be vented to the outside

in accordance with the current edition of the National Fuel

Gas Code ANSI-Z223.1 (In Canada, the current CAN/CSA

B149.1 installation code). The insert must not be connected

to a chimney flue serving a separate solid fuel burning ap-

pliance.

This gas insert requires a 3” diameter listed flex liner. The

vent should terminate with a listed direct vent termination

cap. The chimney should be sealed around the cap to pre-

vent air and rain from entering the chimney. Adhere to the

vent manufacturer's instructions for installation and vent

termination. These appliances are approved for use with

the following vent kits.

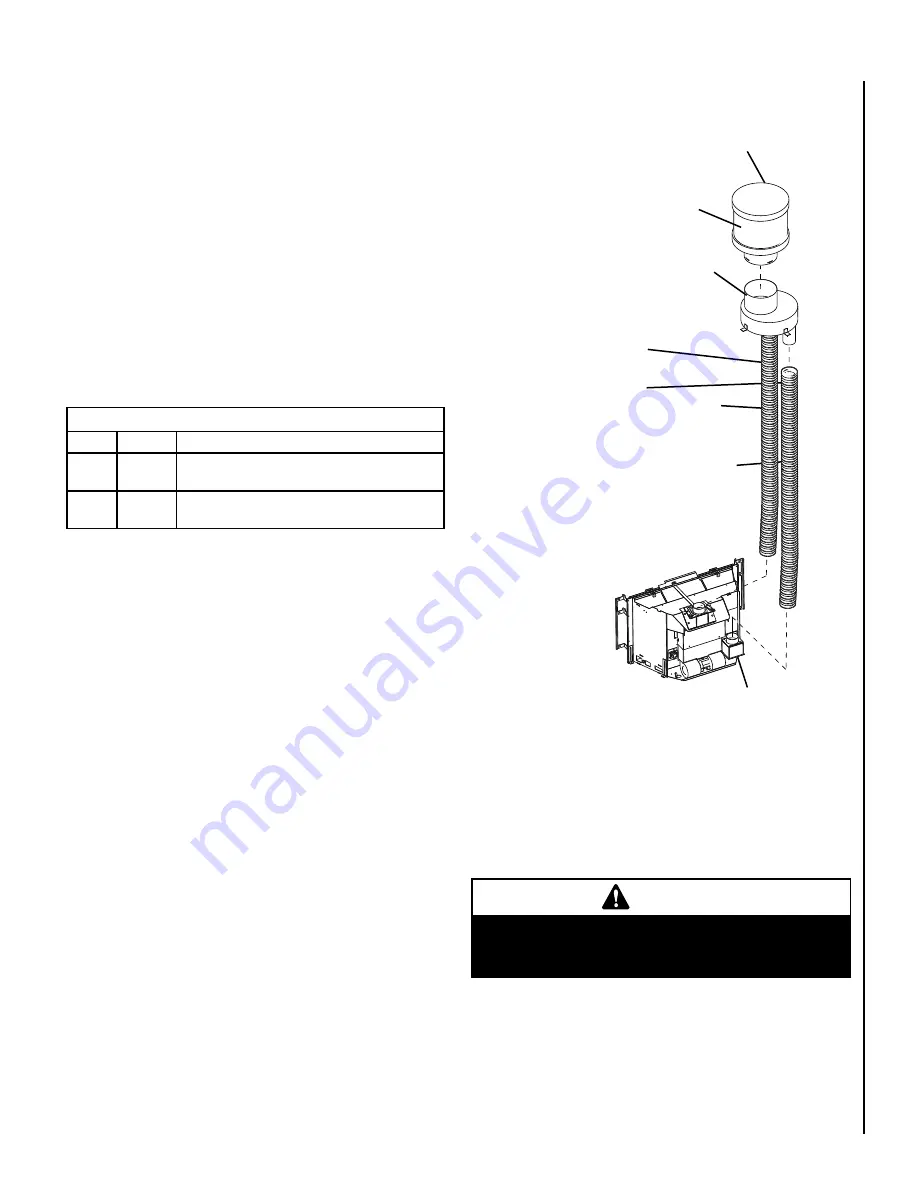

Vertical Cap

Termination

Connector

Exhaust

Intake

Combustion Air Intake

The existing fireplace chimneys may take

various contours which the flexible liners will

accommodate. However, keep the flexible liner

as STRAIGHT as possible, avoid unnecessary

bending.

Liner Requirements:

Vertical Height Min. = 10 ft. (.1 M)

Vertical height Max. = 5 ft. (10.7 M)

Note: Measured from flue collar on

unit to the end of the vent pipe or liner

Use " (7 mm) diameter listed gas

vent liner (UL1777 ONLY) for the

EXHAUST

Use " (7 mm) diameter listed

liner (UL 181 or UL1777) for the

AIR INTAKE.

The flexible vent pipe

must NOT be allowed to

sag behind insert or in

fireplace flue.

The standard cap

in Termination Kit,

H0908, is a high

wind cap

Make sure that both liners will pass through existing damper area. Remove

or lock damper to allow the passage of the flexible liners. If the damper

will not allow the passage of both liners, DO NOT PROCEED FURTHER.

(If fireplace is masonry) Consult a local mason for removal of the damper

without risk of structural damage or leakage (if the fireplace is factory

built) The appliance may NOT be installed into the fireplace.

WARNING

Do not substitute the heat-rated flex liner (UL1777) for the

exhaust with any other type liner or a fire may result caus-

ing property damage, personal injury or loss of life.

Figure