Clearances to non-combustibles

Non-combustible surfaces are defined as brick, metal, marble, concrete

etc. and also a number of man-made materials impervious to flame. If in

doubt refer to the material manufacturer for further information before

proceeding with installation.

Clearances to the sides of the appliance are 4”. Clearance to the front of

the appliance is 20”.

The back of the appliance may be installed directly onto a non-combustible

wall, providing the area behind the appliance is flat and does not interfere

with the various vent holes in the back panel of the appliance.

The appliance may be installed with or without a non-combustible hearth. If

a hearth is fitted, the size and design may be as desired.

A non-combustible shelf of any depth may be positioned above the

appliance provided it is no closer than 16” from the top of the appliance

glass panel and the wall above the appliance is non combustible.

Clearances to combustible materials

Combustible materials are defined as wood, fabrics, or other materials

likely to combust if exposed to flame. Generally, any material, which is likely

to discolour, melt or misshape when exposed to moderate heat, should be

considered as a combustible material or surface.

Clearance to the sides of the appliance are 4” but curtains, drapes and

other fabrics are not permitted within a distance of 20” of the appliance

sides. No such materials are permitted directly above the appliance

regardless of distance.

The minimum clearance to the ceiling above the appliance is 32” measured

from the top of the appliance glass panel.

Combustible materials should not be positioned directly in front of the

appliance within a distance of 40”.

Under no circumstances should any electrical equipment e.g. plasma

screen TV sets etc. be positioned on the wall above the appliance. The

appliance is designed to be wall mounted alone and not in conjunction with

any type of combustible fire surround.

No combustible shelves should be positioned on the wall above the

appliance.

It should be established that any mirrors or picture frames etc. to be

positioned on the wall above the appliance are able to withstand prolonged

exposure to moderate heat and moisture before proceeding with their

installation.

The back of the appliance may be installed directly onto a combustible wall,

providing it is flat and does not interfere with the various vent holes in the

back panel of the appliance. The wall must be structurally sound and

constructed from a material capable of withstanding moderate heat.

Finished plaster, conventional wall paper and dry-lined plasterboard are

examples of suitable materials. Materials such as flock, blown vinyl and

embossed paper which are sensitive to even small amounts of heat should

be avoided as scorching and or discoloration may occur over time.

If the appliance is to be mounted on a dry-lined wall or a timber framed

construction wall then the integrity and ability of the wall to carry the weight

of the appliance must be confirmed. It is important in these circumstances

that any vapor control barrier is not damaged, and that any structural

members of the house frame are not damaged.

The appliance may be positioned as close to a solid floor (i.e. stone,

wooden laminate etc.) as the particular design of fire frame permits,

however it is not permitted to install the appliance within 4” of carpet, rugs

or fabric materials of any kind. This dimension is measured vertically to the

bottom of the appliance frame.

Gas connection :

The heater gas inlet connection is 3/8” NPT at the

regulator, located below the burner, in the center of the heater.

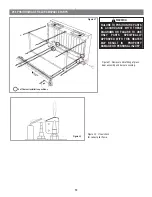

There are four possible

entry points for the gas

supply pipework to enter

the appliance firebox.

These entry points are

‘knock out’ type holes

(shown in figure 1).

Non-concealed gas

connections may be

made using the entry

points on the base of the

firebox. A

concealed

gas connection may be

made using the knock

out hole in the centre

back of the firebox.

Select the most

appropriate entry point and knock out the relevant hole.

If a concealed gas connection is to be made, the supply pipe should always

be sleeved through walls and floors using the shortest possible route.

For concealed supply pipe routing, pipes must (where possible) be vertical

and providing there is sufficient wall thickness available, they should be

placed in pipe chases. Horizontal pipe runs should be avoided where

possible. Prior to chasing a solid wall, an inspection should be made to note

the proximity of any cables/sockets outlets which may already be buried.

Pipes must be secured using suitable clips and protected against corrosion.

Ideally factory finished protected pipework and fittings should be used.

Joints should be kept to a minimum and compression fittings must not be

used. The pipework installation must be tested for soundness before any

protection is applied and/or the pipework and fittings are buried.

After having selected the final mounting position of the appliance, taking

into account the site requirements as specified in section 7 of these

instructions, the integrity of the wall, and the feasibility of the proposed

supply pipe routing, the firebox of appliance may be secured to the wall.

5

7.0 SITE REQUIREMENTS (continued)

8.0 PREPARING THE APPLIANCE

9.0 MOUNTING THE APPLIANCE

Figure 1

DO NOT USE A BLOWER INSERT, HEAT EXCHANGER

INSERT OR OTHER ACCESSORY NOT APPROVED FOR

USE WITH THIS HEATER.

WARNING

DO NOT ALLOW ANY FANS TO BLOW DIRECTLY INTO

THE FIREPLACE. AVOID ANY DRAFTS THAT ALTER

BURNER FLAME PATTERNS.

WARNING