19

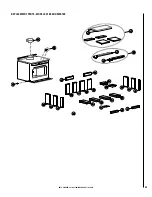

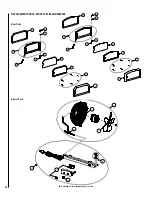

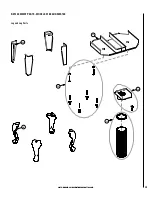

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

DOOR HINGES:

If door hinges need lubricating, use an anti-seize com-

pound (never use oil) available from your Lennox Hearth Products dealer.

DOOR LATCH:

If your door latch fails to latch tightly and the gasket is

in good condition, place a length of pipe (cheater bar) over the inside

portion of the door handle and bend slightly toward the door until the

proper adjustment is obtained. If the door handle does not close easily,

apply high temperature anti-seize to the striker.

DOOR GASKET:

Periodically check gasket to make sure it is not over-

compressed. If compressed, replace with a special woven Door Rope.

(Don’t try substituting rope, only use special Lennox Hearth Products

Door Rope).

PLATED ACCESSORIES:

Clean only with household type glass cleaner

and a very soft cotton cloth. Other products may damage plated finish,

paint and gaskets.

BAFFLE BLANKET:

Your baffle blanket should be inspected during every

chimney cleaning. If the baffle blanket is compressed or heavily stained,

it should be replaced. Heavy creosote stains or matting is an indication

of improper use and your burning habits should be reviewed.

GLASS CLEANING:

Only clean glass with products specifically made to

use on wood stoves. Other products could damage gaskets and paint.

Never scrape glass with a razor blade. This can pit the glass and make it

impossible to clean in the future.

WINDOW GASKET:

The window gasket can be checked by running the

flame of a match near the gasket and around the door. If the flame is

drawn in around the window, the gasket should be replaced.

DOOR HANDLE:

Door handle may become tight as you use the stove.

Free the handle up by using dry graphite supplied with the stove. The

directions are included with the graphite.

WARNING

Inspect and clean chimney and connector frequently.

Under certain conditions of use, creosote buildup

may occur rapidly.

MAINTENANCE

CAUTION

Cleaning Glass: Ensure appliance is cold prior

to cleaning glass. A commercial glass cleaner

designed for stoves is recommended. Do not use

abrasive cleaners. Do not clean with any materials,

which may scratch or otherwise damage the glass.

Scratches on the glass can develop into cracks or

break. Inspect the glass regularly. If you detect a

crack, extinguish the fire and contact your dealer

for a replacement.

GLASS CLEANING GUIDELINES

WARNING: DO NOT CLEAN GLASS WHEN APPLIANCE IS HOT!

Glass on any wood stove or fireplace insert will not stay perfectly clean.

Here are some guidelines for cleaning and caring for the glass:

• Ensure the stove or fireplace insert is cold prior to cleaning glass.

• This appliance is designed to provide a flow of air over the inside of

the glass, where along with high heat helps inhibit build-up on the

glass. When build-up occurs, a commercial glass cleaner designed

for stoves is recommended. Regular household glass cleaners will

not clean creosote.

• Do not use abrasives such as steel pads, steel wool or oven cleaner

as they will scratch the glass. Never scrape glass with a razor blade

as this may pit the glass and make it impossible to clean in the future.

• Do not use chemical glass cleaners as they may damage the gaskets

or painted surfaces.

TIPS FOR KEEPING THE GLASS CLEAN

• Burn only dry seasoned cord wood.

Wet wood = Dirty glass.

• A short, hot fire (15 - 20 minutes) may help to clean off some of the

normal buildup.

Lower burns = more build-up. Higher burns = less

build-up.

• Keep freshly loaded wood away from the glass.

• After reloading, allow all the wood to catch flame before dampering

down the stove or fireplace insert.

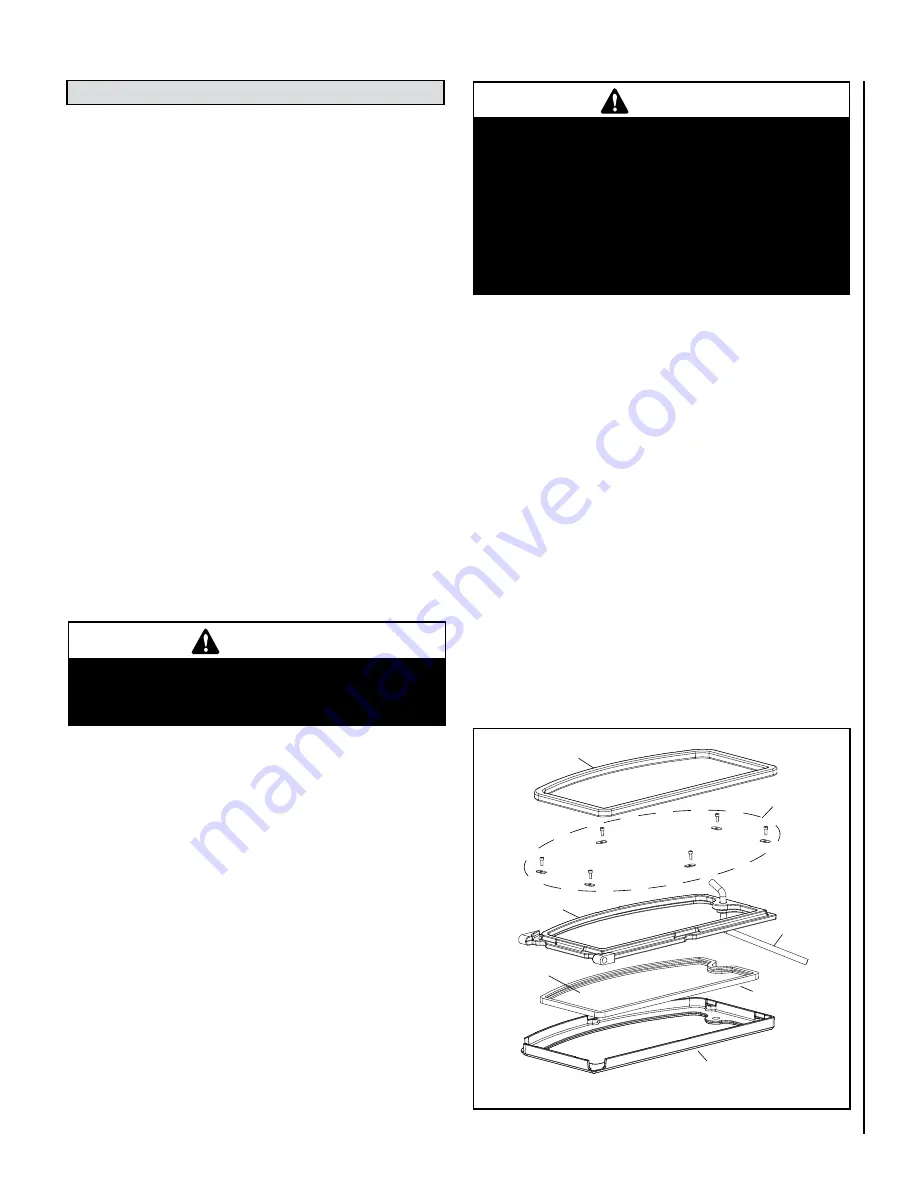

GLASS REPLACEMENT INSTRUCTIONS

Step 1. Remove Door Assembly

- Open door to remove E clip from the upper

hinge pin. Remove upper hinge pin by pulling up while holding the op-

posite side of the door. Lift door out of the lower hinge pin and place

face down on a soft surface.

Step 2.

Remove Door Back Screws (6 ea.)

- Using a 5/32” allen wrench remove

the 6 retainer screws from the faceplate. To locate screws, peel back the

door gasket as necessary.

Step 3.

Disassemble Door Assembly

- Flip door assembly over to be face up.

Separate faceplate from door back by pulling up on faceplate.

Step 4.

Remove Glass

- Carefully remove broken glass one piece at a time

(protective gloves are recommended)

Step 5.

Install New Glass Assembly

- Install the new glass with gasket in recess

on door back (use only factory supplied 5mm ceramic glass. Do not

substitute).

Step 6.

Reinstall Faceplate and Screws

- Reinstall faceplate onto door back

and while holding the door assembly together flip the assembly back

onto it’s face. Carefully reinstall the screws. Be very careful not to

overtighten the screws (this could result in glass breakage when the

stove or fireplace insert is hot) and it is highly recommended to use anti

seize on the screws.

Step 7.

Reinstall Door

- Set door assembly back into the lower hinge mount

while holding the handle side of the door up. Place the upper hinge

pin back in the mount and door assembly. Reinstall the E clip that was

removed.

Figure 20

Faceplate

Glass Gasket

Glass

Door Back

Handle Rod

Door Gasket

Screws and

Washers

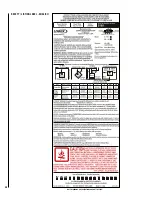

Summary of Contents for STRIKER S160

Page 23: ...23 NOTE DIAGRAMS ILLUSTRATIONS ARE NOT TO SCALE Replacement Parts Models S160 and SWS160 ...

Page 30: ...30 NOTE DIAGRAMS ILLUSTRATIONS ARE NOT TO SCALE SAFETY LISTING LABEL eNGLISH 2011 2012 2013 ...

Page 31: ...31 NOTE DIAGRAMS ILLUSTRATIONS ARE NOT TO SCALE SAFETY LISTING LABEL FRENCH ...