Page 4

FILTERS

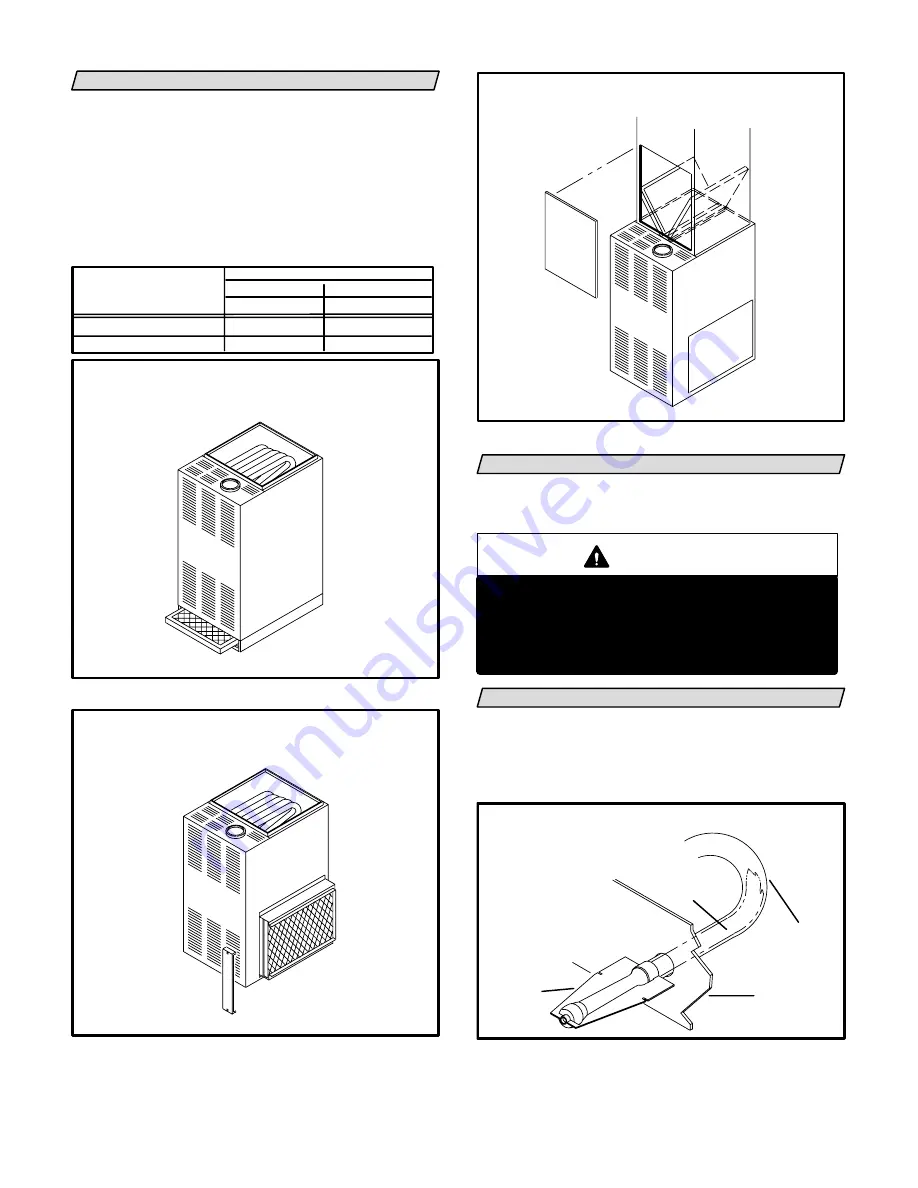

80MGF series units are equipped with external filters

which should be inspected monthly and replaced when

necessary to assure proper furnace operation. See table

1 for filter sizes. Replacement filters used with

80MGF-40/60/75 units must have a minimum velocity ratĆ

ing of 400 FPM. Replacement filters used with

80MGF-100/120/140 units require a minimum velocity

rating of 625 FPM. Figures 3, 4 and 5 show possible filter

locations.

TABLE 1

MODEL NO.

FILTER SIZE

80MGF-45/60/75

16" X 20" X 1"

UPFLOW

DOWNFLOW

16" X 20" X 1"

1 FILTER

2 FILTERS

80MGF-100/120/140

20" X 20" X 1"

16" X 20" X 1"

UPFLOW FURNACE

BOTTOM RETURN AIR

FIGURE 3

UPFLOW FURNACE

SIDE RETURN AIR

FIGURE 4

DOWNFLOW FURNACE

FILTERS IN PLENUM RACK

FIGURE 5

BLOWER

Check and clean blower wheel for any debris. Blower moĆ

tor is prelubricated for extended bearing life. No further luĆ

brication is needed.

WARNING

Blower door must be securely in place when

blower and burners are operating. Gas fumes,

which could contain carbon monoxide, can be

drawn into living space resulting in personal inĆ

jury or death.

BURNER FLAME

The 80MGF burner flame is not adjustable; however, the

flame should be inspected at the beginning of each heatĆ

ing season and burners should be cleaned, if necessary.

Burner flame should be blue when burning natural gas,

blue/yellow when burning propane gas.

BURNER FLAME

FIGURE 6

BURNER

FLAME

HEAT

EXCHANGER

TUBE

VEST

PANEL

FLAME APPEARS BLUE IF

BURNING NAT. GAS; BLUE/

YELLOW FOR PROPANE.