Page 13

senses rollout, the ignition control immediately stops igniĆ

tion and closes the gas valve. If unit is running and flame

rollout is detected, the gas valve will close and ignition conĆ

trol will be disabled. Rollout can be caused by a blocked

flue or lack of combustion air. The switch is factory set and

cannot be adjusted. The setpoint will be printed on the side of

the limit. The switch can be manually reset. To manually reĆ

set a tripped switch, push the reset button located on the

control.

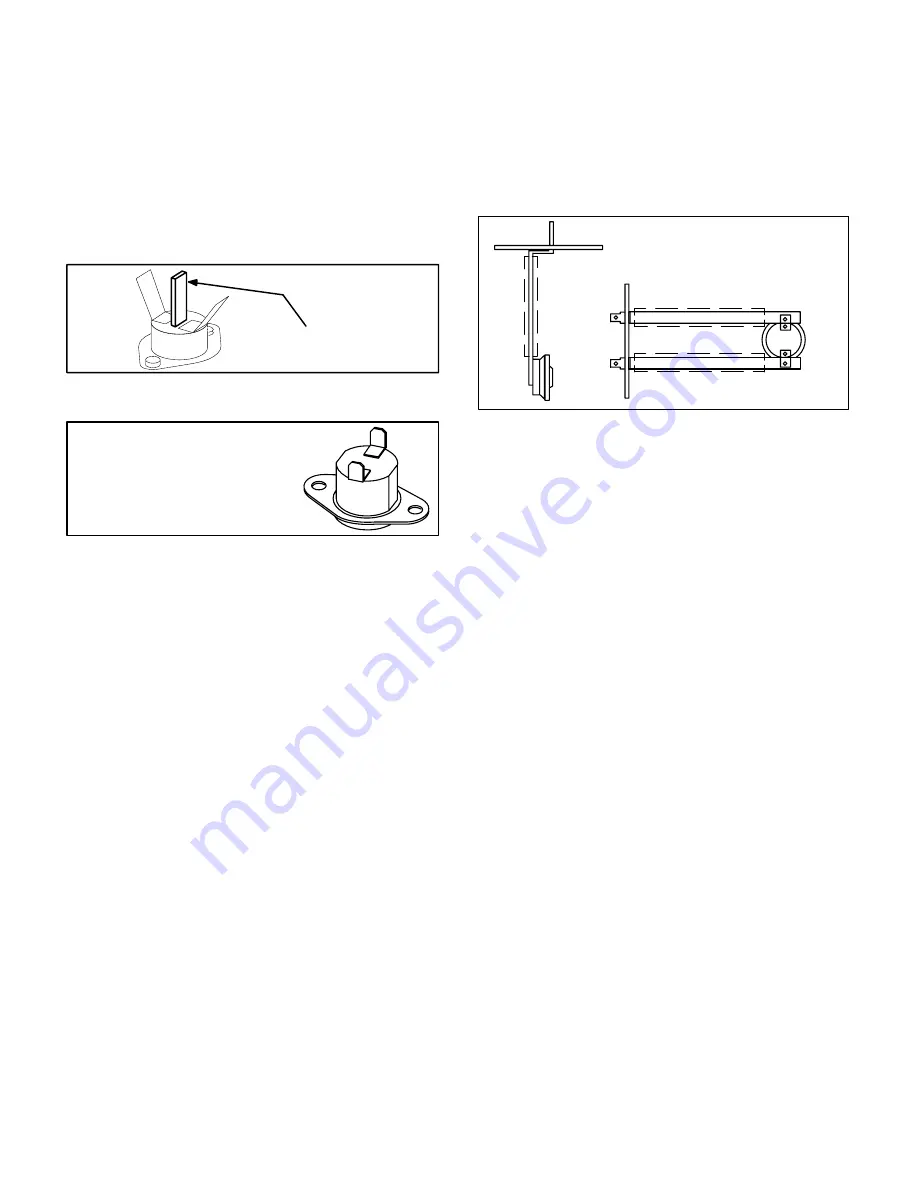

FIGURE 12

ROLLOUT SWITCH (S47)

MANUAL

RESET BUTTON

9-Primary Limit Control (S10)

FIGURE 13

80UHG SERIES UNITS

LIMIT CONTROL FOR

THIS TYPE AUTOĆRESET LIMIT

IS USED FOR THE PRIMARY LIMIT (S10) AND

RIGHT SECONDARY LIMIT (S21)

(see FIGURE 11)

The primary limit (S10) on 80UHG units is located in the

middle of the heating vestibule panel. When excess heat is

sensed in the heat exchanger, the limit will open. If the limit is

tripped, the furnace control energizes the supply air blower

and closes the gas valve. The limit automatically resets when

unit temperature returns to normal. The switch is factory set

and cannot be adjusted. The switch may have a different

setpoint for each unit model number. However, the setpoint

will be printed on the side of the limit.

10-Secondary Limit Controls (S21)

The secondary limit (S21) on 80UHG units is located in the

blower compartment in the back side of the blower housing.

When excess heat is sensed in the blower compartment, the

limit will open. If the limit is tripped, the furnace control enerĆ

gizes the supply air blower and closes the gas valve. The limit

automatically resets when unit temperature returns to normal.

The switch is factory set and cannot be adjusted. The setĆ

point will be printed on the limit.

Two limits are supplied in each furnace. 80UHG3, 80UHG4

and 80UHG4/5 model units

built prior to Apri 1999, will

have one each of style shown in figures 13 and 14. If stick

limit (figure 14) suffers frm nuisance trips on the above

model units and the furnace is in the horizontal position, reĆ

place with limit kit no. 50L98. All 80UHG2 model units will

have one of each style shown in figures 13 and 14.

INSULATING COVER (s)

FIGURE 14

SECONDARY LIMIT CONTROL (S21)

FOR 80UHG SERIES UNITS

SP

ADE CONNECTORS

INSULA

TING COVER

LIMIT

LIMIT

THIS TYPE AUTOĆRESET LIMIT IS

USED FOR THE LEFT SECONDARY

LIMIT (S21) (see FIGURE 11)

11-Spark Electrode and Flame Sensor

80UHG-1 Models

Figure 17 shows the arrangement of flame sensor, spark

electrode and burners. The ignition control uses direct

spark to ignite the rightmost burner and the burners crossĆ

light to the left. The flame sensor uses flame rectification to

sense combustion. A flame retention ring in the end of

each burner is used to maintain correct flame length and

shape and to keep the flame from lifting off the burner

head.

Figure 18 shows the gap between tip of the electrodes and

the burner surface, and the gap between the sensor and

burner surface.

12-Gas Valve

The 80UHG uses a gas valve manufactured by HoneyĆ

well or White Rodgers. The valve is internally redundant to

assure safety shut-off. If the gas valve must be replaced,

the same type valve must be used.

24VAC terminals and gas control knob are located on top of

the valve. All terminals on the gas valve are connected to

wires from the electronic ignition control. 24V applied to the

terminals energizes the valve.

Inlet and outlet pressure taps are located on the valve. A reguĆ

lator adjustment screw (figures 15 and 16) is located on the

valve.

LPG changeover kits are available from Lennox. Kit s include

burner orifices and a gas valve regulator conversion kit.