# 47860A005

Page 23

Primary Limit Control

This is a normally closed control that opens if abnormally

high circulating air temperatures occur. It is an automatic

reset control.

Auxiliary Limit Control

This is a normally closed control that opens under abnor-

mal “reverse air flow” conditions that could occur in a

counterflow or horizontal installation if the circulating

blower fails. It is an automatic reset control.

Interlock (Blower Door) Switch

When the blower door is removed, the interlock switch

breaks the power supply to the burner controls and blower

motor. The switch operation must be checked to confirm it

is operating correctly.

Blower Control Board

The blower control board operates the circulating air

blower, the combustion blower and any accessories

connected to it. These models feature user-selectable

blower “off” delay times (60, 90, 120, and 180 seconds)

that are factory set to provide a 120-second blower “off”

delay on heating (see wiring diagram on page 27).

Refer to the furnace wiring diagram while using the

following procedure to change motor speed:

1. Turn off electrical power to the unit.

2. Connect the desired speed tap for cooling on the

blower control board.

3. For heating speed, check the temperature rise and, if

necessary, adjust the blower speed tap to maintain

temperature rise within the range shown on the

furnace rating plate.

To use the same speed tap for both heating and

cooling, install a piggyback terminal on the speed tap

using a short jumper. Wire 1/4" quick connect termi-

nals on both ends to jumper the “HEAT” and “COOL”

speed on the blower control board.

4. The remaining speed taps must be connected to

dummy terminals marked “PARK” on the blower

control board.

Checking and Adjusting Gas Input

The minimum permissible gas supply pressure for the

purpose of input adjustment is 5" W.C. for natural gas and

11" W.C. for propane gas. This furnace requires conversion

for use with propane (see

Accessories

section on page 26

for correct kit). The maximum inlet gas supply pressure is

10.5" W.C. for natural gas and 13" W.C. for propane.

Gas input must never exceed the value shown on the

furnace rating plate. The furnace is equipped for rated

input at manifold pressures of 3.5" W.C. for natural gas or

10.0" W.C. for propane gas.

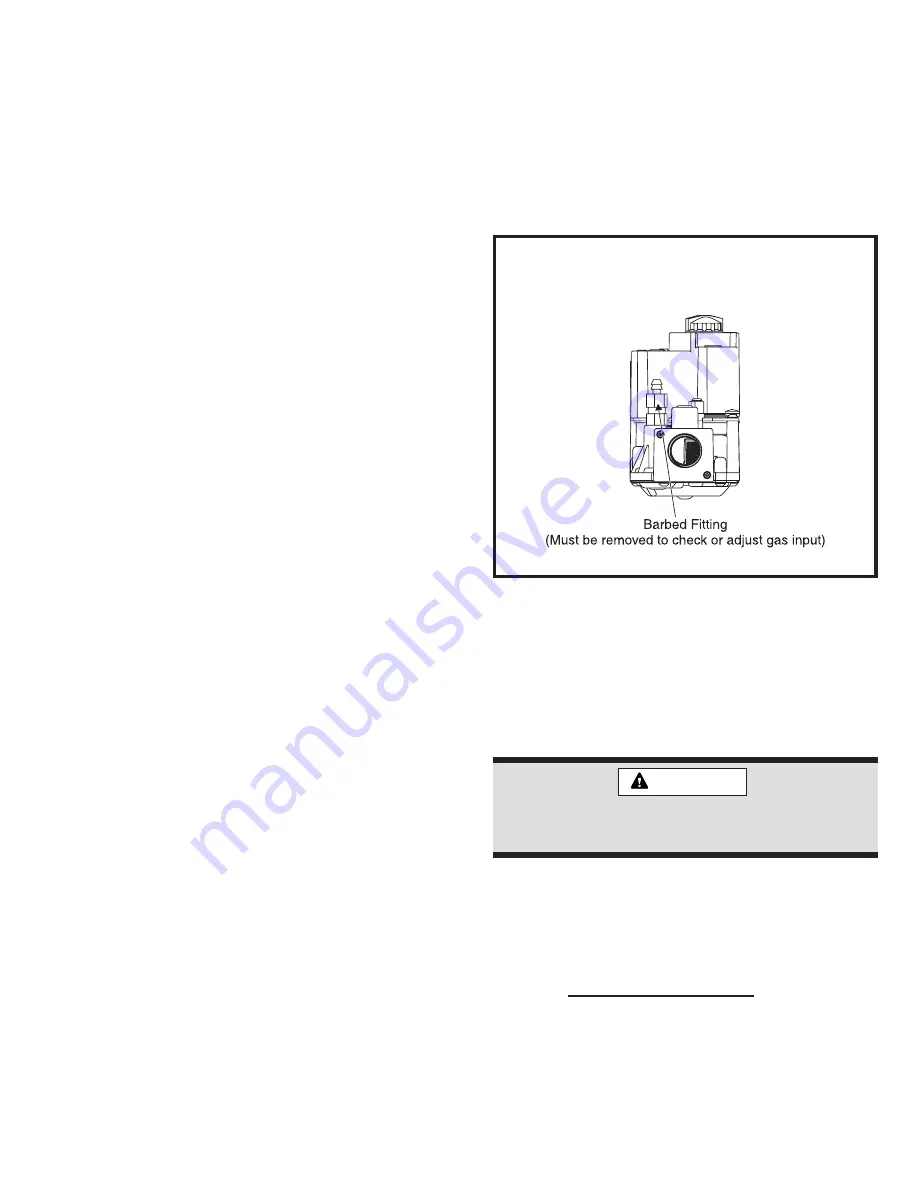

To measure the manifold pressure, disconnect the hose

and remove the barbed fitting in the downstream side of

the gas valve and connect a water manometer or gauge

(see Figure 33).

To adjust the regulator, turn the adjusting screw(s) on the

regulator clockwise to increase pressure and input; coun-

terclockwise to decrease pressure and input.

Replace the barbed fitting and reconnect the hose after

measuring and/or adjusting the regulator.

Figure 33

Checking and Adjusting

Gas Input

For Natural Gas:

Check the furnace rate by observing

the gas meter, when available, making sure all other gas

appliances are turned off. The test hand on the meter

should be timed for at least one revolution. Note the

number of seconds for one revolution.

x

3600 x

= Cubic Feet Per Revolution

BTU/HR

INPUT

# Seconds Per Revolution

Heating

Value

The heating value of the gas can be obtained from the local

utility company.

For Propane Gas:

The only check for the furnace rate is to

properly adjust the manifold pressure using a manometer

The furnace rate must be /- 2% of the

appliance rating input.

CAUTION