Page 5

Filters

All EL180UHNE filters are installed external to the unit. Fil

ters should be inspected monthly. Clean or replace the fil

ter(s) when necessary to ensure proper furnace operation.

A filter must be in place when the unit is operating.

See

table 1 for recommended filter sizes.

NOTE -

Use replacement filters that are similar in size and

efficiency ratings to those originally provided by the in

stalling contractor. Use of replacement filters with higher fil

tration ratings may restrict air flow to the furnace. This may

result in reduced unit efficiency, as well as premature blow

er motor failure.

A filter must be in place when the unit is operating.

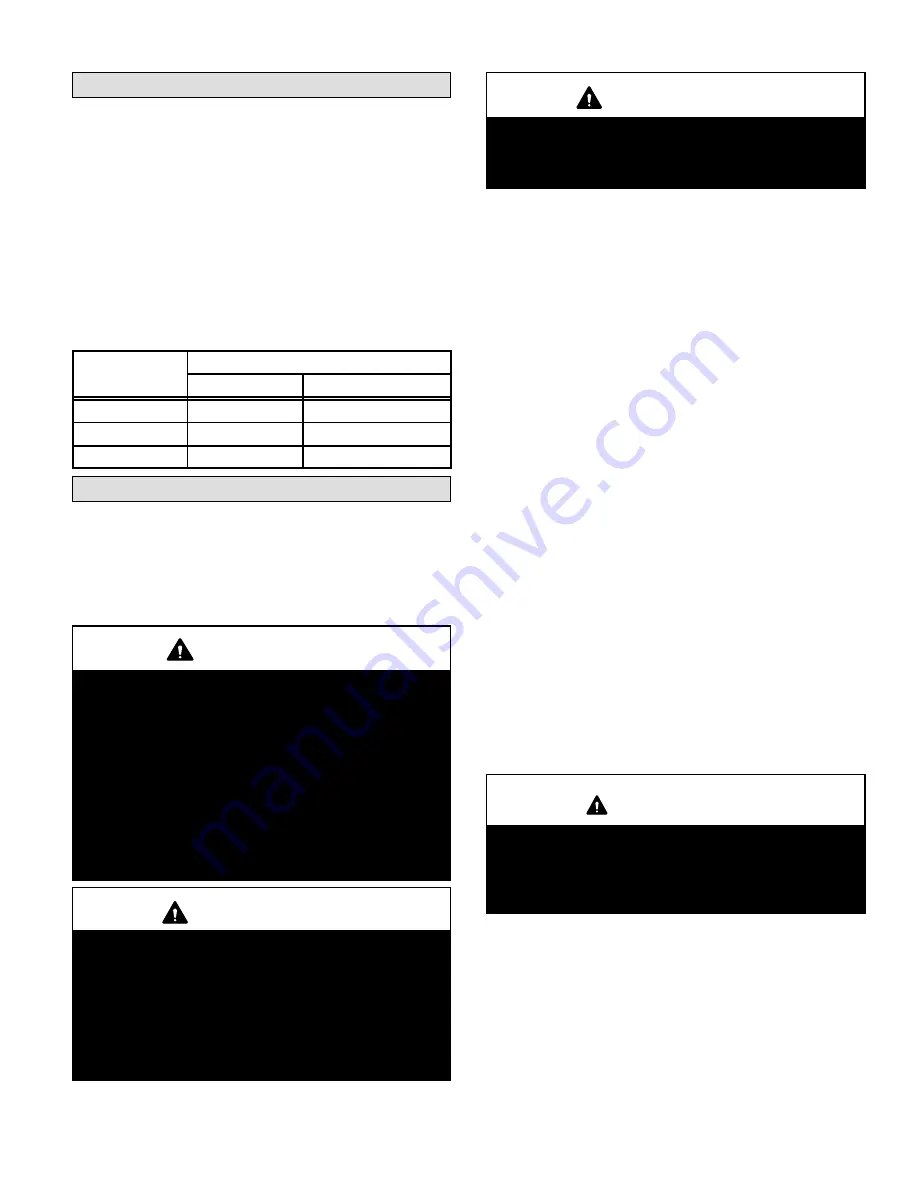

TABLE 1

Furnace

Cabinet Width

Filter Size

Side Return

Bottom Return

14-1/2”

16 X 25 X 1 (1)

14 X 25 X 1 (1)

17-1/2”

16 X 25 X 1 (1)

16 X 25 X 1 (1)

21”

16 X 25 X 1 (1)

20 X 25 X 1 (1)

Maintenance

A licensed professional service technician (or equivalent)

should inspect the complete system each season (heating

and cooling). The following maintenance procedures

should only be conducted by a licensed professional ser

vice technician (or equivalent).

Do not attempt to service

the unit in any way.

WARNING

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly could result

in dangerous operation, serious injury, death or

property damage.

Improper servicing could result in dangerous opera

tion, serious injury, death, or property damage.

Before servicing, disconnect all electrical power to

furnace.

When servicing controls, label all wires prior to dis

connecting. Take care to reconnect wires correctly.

Verify proper operation after servicing.

WARNING

Asphyxiation Hazard

The exhaust vent for this furnace must be leak-free

and must be securely connected to the furnace flue

collar at all times.

For your safety and to fulfill the terms of the limited

warranty, a licensed professional service technician

(or equivalent) must annually inspect this furnace

and its vent system.

CAUTION

To ensure proper operation, a licensed professional

service technician (or equivalent) should check the

burner flame and conduct a combustion analysis

annually.

Annually (before heating season) inspect furnace venting

system, vent cap, heat exchanger, and burners for corro

sion, deterioration, or deposits of debris. Remove any ob

structions.

Inspect the furnace for obvious signs of deterioration.

Inspect the furnace venting system to make sure it is in

place, physically sound, and without holes, corrosion, or

blockage.

Vent pipe must be clear and free of obstructions and must

slope upward away from the furnace.

Inspect the furnace return air duct connection to ensure

duct is sealed to the furnace and terminates outside the

space containing the furnace.

Inspect the physical support of the furnace to guarantee

that it is sound without sagging, cracks or gaps around

base and it maintains seal between base and support.

During a seasonal check the service technician will con

duct a combustion analysis. The technician will also in

spect the indoor blower, burner flames, electrical connec

tions and the venting system.

Blower

Check the blower wheel for debris and clean if necessary.

The blower motors are prelubricated for extended bearing

life. No further lubrication is needed.

WARNING

The blower access panel must be securely in place

when the blower and burners are operating. Gas

fumes, which could contain carbon monoxide, can

be drawn into living space resulting in personal inju

ry or death.

Electrical

1 - Check all wiring for loose connections.

2 - Check for the correct voltage at the furnace (furnace

operating).

3 - Check amp-draw on the blower motor with blower ac

cess panel in place.

Motor Nameplate__________Actual__________