Page 14

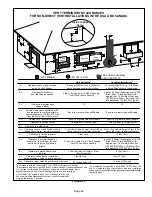

FIGURE 11

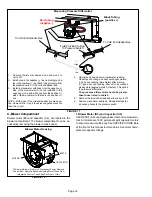

Measuring Pressure Differential

1 − Remove thermostat demand and allow unit to

cycle off.

2 − Install a tee in the negative (−) line (red tubing) and a

tee in the positive (+) line (black tubing) running from

the pressure switch to the cold end header box.

3 − Install a manometer with hose from the negative (−)

side of the manometer to the tee installed in the

negative (−) line and with hose from the positive (+)

side of the manometer to the tee in the positive (+)

line.

NOTE − Both sides of the cold end header box are nega-

tive. However the (+) port reads less negative pressure

than the (−) port.

4 − Operate unit and observe manometer reading.

Readings will change as heat exchanger warms.

a. Take one reading immediately after start-up.

b. Take a second reading after unit has reached

steady state (approximately 5 minutes). This will be

the pressure differential.

The pressure differential should be greater

than those listed in table 5.

5 − Remove thermostat demand and allow to cycle off.

6 − Remove manometer and tee’s. Reinstall combustion

air sensing hoses to the pressure switch.

To Cold End Header Box

Field Provided Tubing

To Pressure Switch

To Cold End Header Box

Black Tubing

(po)

Red Tubing

(negative −)

+"

High

−"

Low

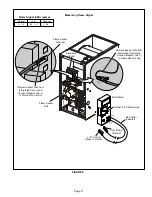

C−Blower Compartment

Blower motor (B3) and capacitor (C4), are located in the

blower compartment. The blower compartment can be ac-

cessed by removing the blower access panel.

FIGURE 12

Blower Motor Housing

To Remove Blower From Unit: Disconnect Power, Remove

Control Box, Remove Bolts and Unplug Motor Wires From

Integrated Control. Then Slide Out Front of Unit.

MOTOR

CAPACITOR

BOLTS

1.Blower Motor (B3) and Capacitor (C4)

All EL195DF units use single−phase direct−drive blower mo-

tors. All motors are 120V permanent split capacitor motors

to ensure maximum efficiency. See SPECIFICATIONS table

at the front of this manual for more detail. See motor name-

plate for capacitor ratings.