Page 27

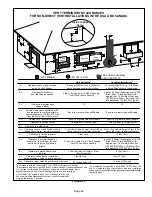

Details of Intake and Exhaust Piping Terminations for

Direct Vent Installations

NOTE

− In Direct Vent installations, combustion air is tak-

en from outdoors and flue gases are discharged to out-

doors.

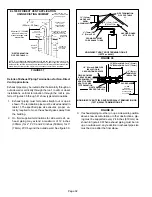

NOTE

− Flue gas may be slightly acidic and may adversely

affect some building materials. If any vent termination is

used and the flue gasses may impinge on the building ma-

terial, a corrosion−resistant shield (minimum 24 inches

square) should be used to protect the wall surface. If the

optional tee is used, the protective shield is recommended.

The shield should be constructed using wood, plastic,

sheet metal or other suitable material. All seams, joints,

cracks, etc. in the affected area should be sealed using an

appropriate sealant. See figure 27.

Intake and exhaust pipes may be routed either horizontally

through an outside wall or vertically through the roof. In attic

or closet installations, vertical termination through the roof

is preferred. Figures 25 through 37 show typical termina-

tions.

1. Exhaust and intake exits must be in same pressure

zone. Do not exit one through the roof and one on the

side. Also, do not exit the intake on one side and the

exhaust on another side of the house or structure.

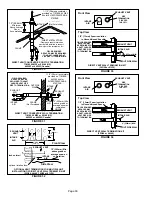

2. Intake and exhaust pipes should be placed as close

together as possible at termination end (refer to il-

lustrations). Maximum separation is 3" (76mm) on roof

terminations and 6" (152mm) on side wall termina-

tions.

3. On roof terminations, the intake piping should termi-

nate straight down using two 90° elbows (See figure

25).

4. Exhaust piping must terminate straight out or up as

shown. A reducer may be required on the exhaust pip-

ing at the point where it exits the structure to improve

the velocity of exhaust away from the intake piping.

See table 11.

TABLE 11

EXHAUST PIPE TERMINATION SIZE REDUCTION

EL195

MODEL

Exhaust Pipe Size

Termination

Pipe Size

*045 and *070

2" (51mm), 2−1/2" (64mm),

3" (76mm)

1−1/2" (38mm)

*090

2" (51mm)

110

2" (51mm)

*EL195DF−045, −070 and −090 units with the flush−mount termination

must use the 1−1/2"accelerator supplied with the kit.

5. On field−supplied terminations for side wall exit, ex-

haust piping may extend a maximum of 12 inches

(305mm) for 2" PVC and 20 inches (508mm) for 3"

(76mm) PVC beyond the outside wall. Intake piping

should be as short as possible. See figures 28 and 29.

NOTE

− Care must be taken to avoid recirculation of

exhaust back into intake pipe.

6. On field supplied terminations, a minimum distance

between the end of the exhaust pipe and the end of

the intake pipe without a termination elbow is 8" and a

minimum distance of 6" with a termination elbow. See

figures 28 and 29.

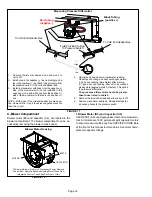

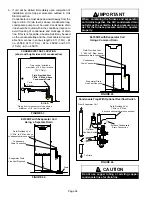

FIGURE 25

UNCONDITIONED

ATTIC SPACE

1/2" (13mm) FOAM

INSULATION IN

UNCONDITIONED

SPACE

SIZE TERMINATION

PIPE PER TABLE 11.

3"(76mm) MAX.

12" (305mm) ABOVE

AVERAGE SNOW

ACCUMULATION

3" (76mm) OR

2" (51mm) PVC

PROVIDE SUPPORT

FOR INTAKE AND

EXHAUST LINES

8" (203mm) MIN

Inches(mm)

DIRECT VENT ROOF TERMINATION KIT

(15F75 or 44J41)

1−1/2" ACCELERATOR

(all −045, −070 and −090 units)

FURNACE

EXHAUST

PIPE

FURNACE

INTAKE

PIPE

4’’

GLUE EXHAUST

END FLUSH INTO

TERMINATION

FLUSH−MOUNT SIDE WALL TERMINATION KIT 51W11

FIGURE 26

2" EXTENSION FOR

2" PVC PIPE

1" EXTENSION FOR

3" PVC PIPE

7.

I

f intake and exhaust piping must be run up a side wall

to position above snow accumulation or other ob-

structions, piping must be supported every 24"

(610mm) as shown in figures 28 and 29. In addition,

close coupled wall termination kits must be extended

for use in this application. See figures 35 and 36.

When exhaust and intake piping must be run up an

outside wall, the exhaust piping must be terminated

with pipe sized per table 11.The intake piping may be

equipped with a 90° elbow turndown. Using turndown

will add 5 feet (1.5m) to the equivalent length of the

pipe

.

8. A multiple furnace installation may use a group of up to

four terminations assembled together horizontally, as

shown in figure 32.