Page 8

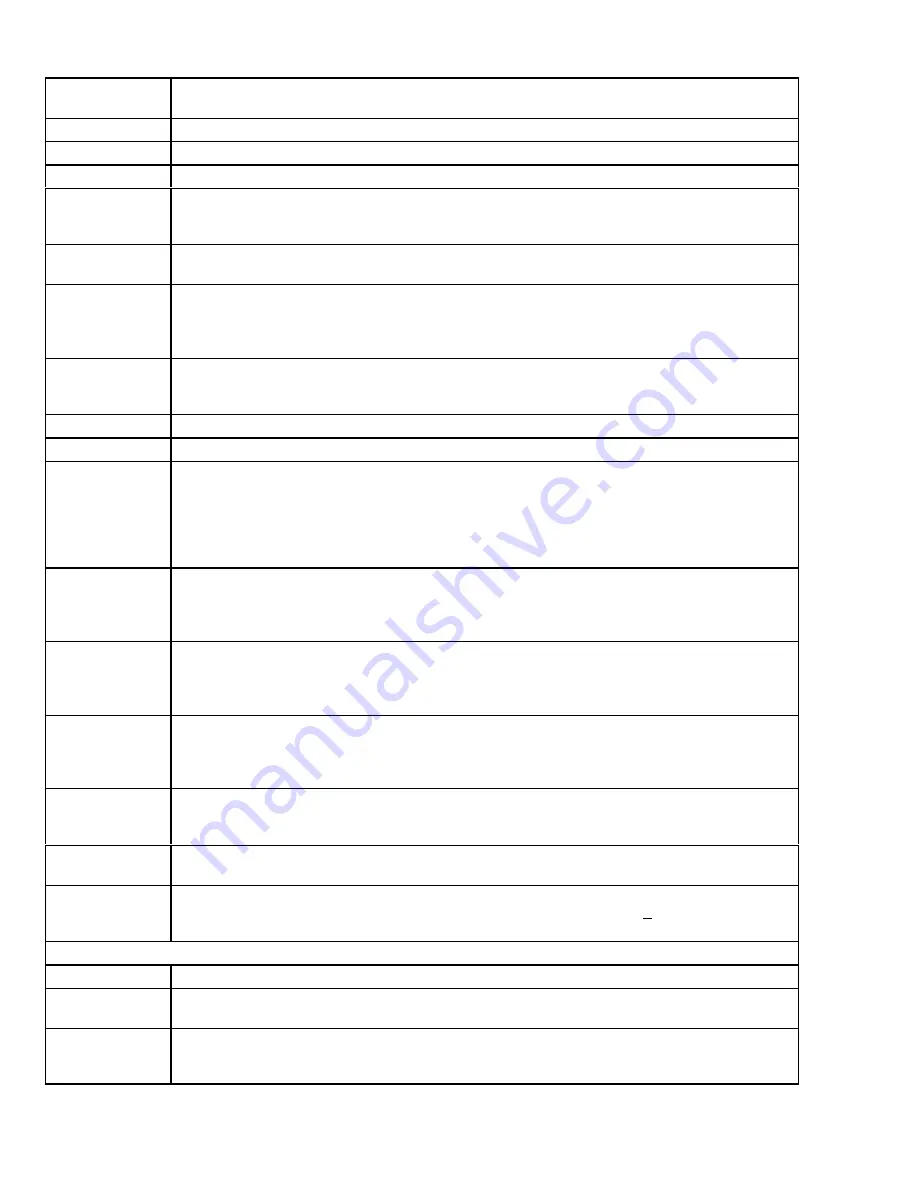

TABLE 3

RED LED

Flash Code

Diagnostic Codes / Status of Furnace

Off

No power to control or board fault detected.

ON

Board Fault Detected.

Heartbeat

1

Control powered − displayed during all modes of operation if no errors are detected.

1

Reverse Line Voltage.

Corrective Action − Check the 120V line and neutral connections and reverse the connection if

necessary.

2

Improper Earth Ground.

Corrective Action − Check for proper unit ground and install if necessary.

3

Burner failed to light, or lost flame during heat demand.

Corrective Action − Check condition of flame sensor and clean if necessary using steel wool.

Check flame sensor signal and replace if necessary.

Check flame sensor wiring and replace if necessary.

4

Low Flame Signal.

Corrective Action − Check flame sensor micro amp reading. Normal reading is 1.5. Replace

sensor if lower than 0.5.

5

Watchguard − burner failed to light, exceeded maximum number of retries or recycles.

6

Ignitor Circuit Failure − not available on this control.

7

Primary or Secondary Limit Open or Watchguard Mode − Limit Switch Open longer than

3 minutes.

Corrective Action

Check for restriction on blower inlet air and outlet air. Remove restrictions.

Check unit rate, rise and static. Make adjustments if necessary and run unit until equilarium.

Check continuity across switch and replace if necessary.

8

Rollout Switch Open.

Corrective Action − Check continuity across switch and replace switch if necessary.

Check for restriction in vent pipe, combustion air inlet and heat exchanger. Determine cause of

restriction before placing furnace back inoperation.

9

Pressure Switch failed to close or opened during heat demand.

Corrective Action − Check the differential in the pressure switch. See figure 11.

Check for restricted vent pipe and remove all blockage.

Check vent pipe sizing. See table 10.

10

Watchguard − Pressure Switch opened 5 times during one heat demand.

Corrective Action − Check for restricted vent pipe and remove all blockage.

Check the condensate line for proper drainage and correct as necessary.

Check for proper vent termination and replace if necessary. See table 8.

11

Pressure Switch stuck closed prior to activation of combustion air inducer.

Corrective Action − Check that the pressure switch is open without the combustion air inducer

operating. Replace switch if defective.

12

Flame Sensed without gas valve energized.

Corrective Action − Check that the gas valve is stuck open. Replace gas valve.

13

Low Line Voltage.

Corrective Action − Check line voltage to unit. Voltage should be 120V + 10%. Contact power

company if necessary.

Notes

Note 1

A "Heartbeat" is indicated by a "Slow Flash" − 1 sec on 1 sec off, repeating

Note

Error codes are indicated by a "Rapid Flash" − the LED flashes X times at 1/2 sec on 1/2 sec

off, remains off for 3 sec, then repeats

Note

Last 10 error codes are stored in memory including when power is shut off to the unit. − To recall,

press and release button, most recent will be displayed first, LED off for 3 sec, then next error

code is displayed, etc. To clear error codes, depress and hold button longer than 5 seconds.