Page 10

WARNING

This furnace is certified for use with type L" vent.

B" vent must not be used with oil furnaces.

NOTE-Oil burning equipment may be vented into an ap

proved masonry chimney or type L vent. (Type L vent is sim

ilar in construction to type B gas vent except it carries a

higher temperature rating and is constructed with an inner

liner of stainless steel rather than aluminum).

Prior to installation of unit, make a thorough inspection of the

chimney to determine whether repairs are necessary. Make

sure the chimney is properly constructed and sized accord

ing to the requirements of the National Fire Protection Asso

ciation. The smallest dimensions of the chimney should be at

least equal to the diameter of the furnace vent connector.

Make sure the chimney will produce a steady draft sufficient

to remove all the products of combustion from the furnace. A

draft of at least .04" w.c. (9.9 Pa) is required during burner

operation.

1 - Local building codes may have more stringent installa

tion requirements and should be consulted before

installation of unit.

2 - The vent connector should be as short as possible to

do the job.

3 - The vent connector should not be smaller than the out

let diameter of the vent outlet of the furnace.

4 - Pipe should be at least 24 gauge galvanized.

5 - Single wall vent pipe should not run outside or through

any unconditioned space.

6 - Chimney should extend 3 feet (0.9 m) above the highest

point where the vent passes through the roof, and 2 feet

(0.6 m) higher than any portion of a building within a hor

izontal distance of 10 feet (3 m).

7 - The vent must not pass through a floor or ceiling. Clear

ances to single wall vent pipe should be no less than 6"

(152 mm); more if local codes require it.

8 - The vent may pass through a wall where provisions have

been made for a thimble as specified in the Standards of

the National Board of Fire Underwriters. See figure 8.

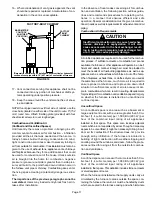

9 - The vent pipe should slope upward toward the chimney

on horizontal run at least 1/4 inch (6 mm) to the foot

(0.3 m) and should be supported by something other

than the furnace, such as isolation hangers. See figure 9.

10- Extend the vent pipe into the chimney so that it is flush

with the inside of the vent liner. Seal the joint between

the pipe and the liner.

11- The furnace shall be connected to a factory built

chimney or vent complying with a recognized stan

dard, or masonry or concrete chimney lined with a

lining material acceptable to the authority having ju

risdiction.

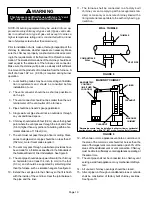

WALL THIMBLE

FIGURE 8

THIMBLE

VENT PIPE

COMBUSTIBLE

WALL

MASONRY CHIMNEY

BAROMETRIC

CONTROL*

(IN EITHER

LOCATION)

CLEANOUT

CLEANOUT

LINER

MASONRY

CHIMNEY

FIGURE 9

*Barometric control may be installed in either vertical or horizontal

section of vent pipe within 18" (457 mm) of vent outlet of furnace.

12- When two or more appliances vent into a common vent,

the area of the common vent should not be less than the

area of the largest vent or vent connection plus 50% of the

areas of the additional vent or vent connection. Chimney

must be able to sufficiently vent all appliances operating at

the same time.

13- The vent pipe shall not be connected to a chimney vent

serving a solid fuel appliance or any mechanical draft sys

tem.

14- All unused chimney openings should be closed.

15- All vent pipe run through unconditioned areas or outside

shall be constructed of factory built chimney sections.

See figure 10.