Page 13

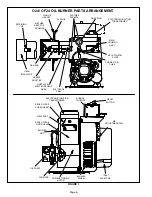

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

OUTLET AIR

INLET AIR

WATER

HEATER

CHIMNEY

OR OIL

VENT

FIGURE 14

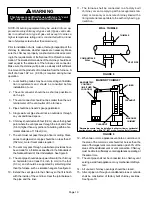

NOTE-Each air duct opening shall have a free area of at least one

square inch (6.4 square centimeters) per 2,000 Btu (586 W) per hour

of the total input rating of all equipment in the enclosure. If the equip

ment room is located against an outside wall and the air openings

communicate directly with the outdoors, each opening shall have a

free area of at least one square inch (6.4 square centimeters) per

4,000 Btu (1172 W) per hour of the total input rating of all other equip

ment in the enclosure.

OIL

FURNACE

When ducts are used, they shall be of the same cross-sec

tional area as the free area of the openings to which they

connect. The minimum dimension of rectangular air ducts

shall be no less than 3" (76 mm). In calculating free area, the

blocking effect of louvers, grilles, or screens must be consid

ered. If the design and free area of protective covering is not

known for calculating the size opening required, it may be

assumed that wood louvers will have 20 to 25 percent

free area and metal louvers and grilles will have 60 to 75

percent free area. Louvers and grilles must be fixed in

the open position or interlocked with the equipment so that

they are opened automatically during equipment operation.

CAUTION

Combustion air openings in the front of the furnace

must be kept free of obstructions. Any obstruction

will cause improper burner operation and may result

in a fire hazard or injury.

CAUTION

The barometric shall be in the same atmospheric

pressure zone as the combustion air inlet to the

furnace. Deviation from this practice will cause im

proper burner operation and may result in a fire

hazard or injury.

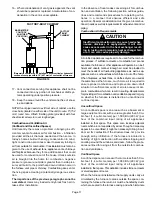

Direct Connection of Outdoor Air for Combustion

The Beckett AFII burner was designed to allow for direct air

intake piping (4" [102 mm]). The maximum equivalent

length of pipe is 70 feet (21.3 m). A 90

elbow equals

6feet (1.8 m).

To convert the AFII burner from confined space to out

side combustion air, simply remove the three screws at

taching the inlet air scoop to the burner and insert 4" (102

mm) direct air intake piping.

The use of a barometric relief placed in the intake pipe is

recommended when outdoor combustion air is directly

connected to the burner. This will allow confined space

air to be used as combustion air in the event that the

opening to the outdoor air becomes blocked. Using a

barometric relief in the intake will reduce the chance of

sooting.

CAUTION

DO NOT USE a barometric draft relief in exhaust

vent pipe if outdoor combustion air is connected

directly to the burner. The only exception are baro

metric draft reliefs as required by FIELD or TJERN

LUND power vents.

Removal of Unit from Common Venting System

In the event that an existing furnace is removed from a venting

system commonly run with separate appliances, the venting

system is likely to be too large to properly vent the remaining

attached appliances. The following test should be conducted

while each appliance is in operation and the other ap

pliances not in operation remain connected to the com

mon venting system. If venting system has been installed

improperly, the system must be corrected as outlined in the

previous section.

1 - Seal any unused openings in the common venting sys

tem.

2 - Visually inspect venting system for proper size and hori

zontal pitch and determine there is no blockage or restric

tion, leakage, corrosion or other deficiencies which could

cause an unsafe condition.

3 - Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliances

not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and bath

room exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

4 - Following the lighting instruction on the unit, place the

appliance being inspected in operation. Adjust thermo

stat so appliance will operate continuously.

5 - Test for spillage using a draft gauge.