Page 28

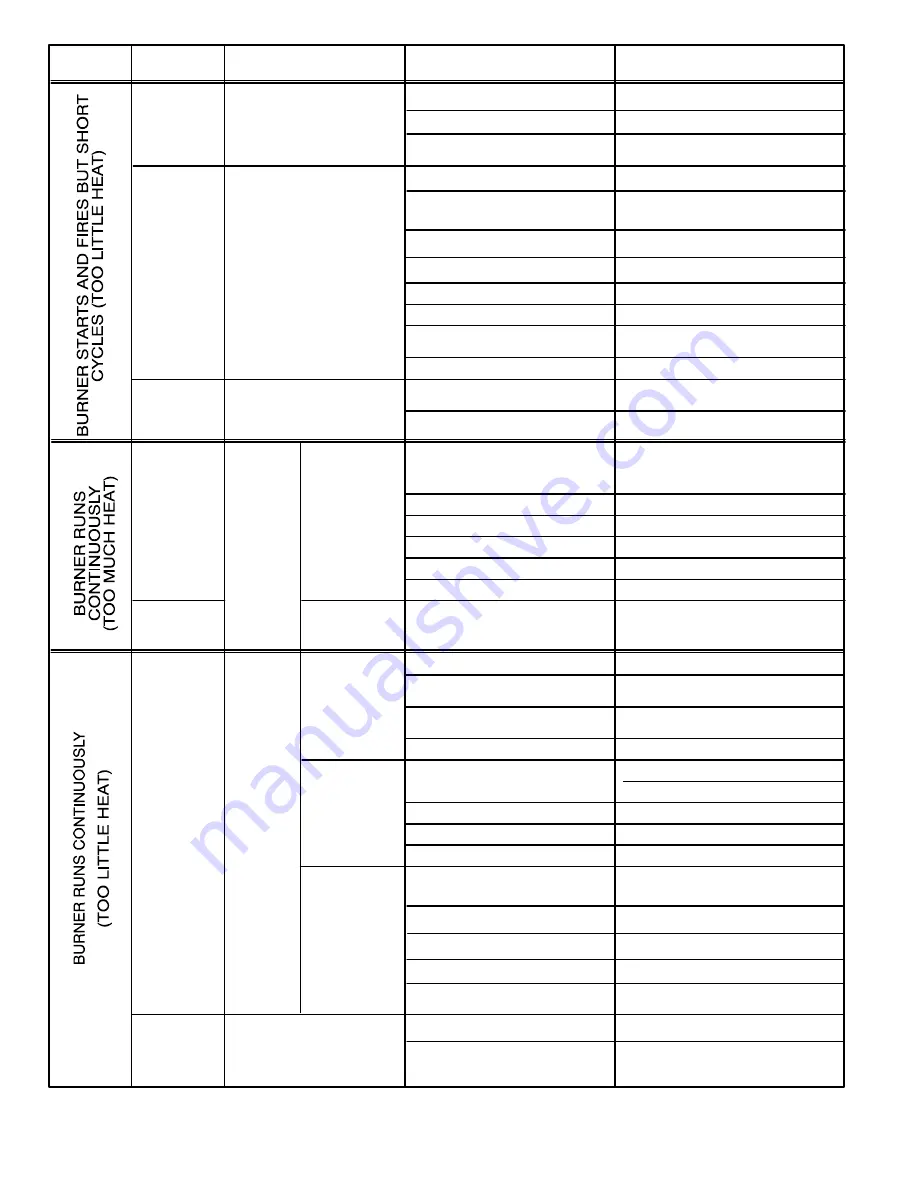

Partially plugged or defective nozzle.

Oil pressure too low, less than

140 (965.3 kPa) psi.

Stuck thermostat bimetal.

Thermostat not level.

Shorted thermostat wires.

Thermostat out of calibration.

Thermostat in cold draft.

Defective primary control.

Too much combustion air.

Excessive draft.

Incorrect burner head adjustment.

Dirty or plugged heat exchanger.

Insufficient draft.

Incorrect burner head adjustment.

Too little combustion air.

Too little blower air.

Dirty or plugged heat exchanger.

Dirty blower wheel.

Dirty furnace air filters.

Restricted or closed registers or

dampers.

Heat anticipator set too low.

Vibration at thermostat.

Replace with properly rotating wheel.

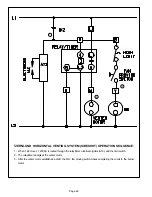

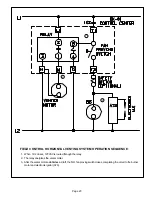

TROUBLE SOURCE

PROCEDURE

CAUSES

CORRECTION

THERMOSTAT

LIMIT

CONTROL

POWER

PRIMARY

CONTROL

THERMOSTAT

COMBUSTION

OIL

PRESSURE

Check thermostat.

Connect voltmeter between

line voltage connections to

primary control (black & white

leads). If burner cycles due to

power interruption, it's cycling

off limit.

If voltage fluctuates, fault is in

the power source. Recheck

voltage at power source.

Disconnect

thermostat

wires at

primary

control.

If burner turns

off, fault is in

thermostat

circuit.

If burner does not

turn off, fault is in

primary control.

Check burner

combustion

for CO

2

,

stack

temperature

& smoke.

Inspect fire and check oil

pressure.

Thermostat in warm air draft.

Dirty furnace air filters.

Blower running too slow.

Blower motor seized or burned out.

Blower wheel in backwards.

Wrong motor rotation.

Restrictions in return or supply air

system.

Adjustable limit control set too low.

Correct heat anticipator setting.

Correct source of vibration.

Shield thermostat from draft or

relocate.

Clean or replace filter.

Increase blower speed to maintain

proper temp. rise.

Replace motor.

Clean blower wheel.

Reverse blower wheel.

Correct cause of restriction.

Blower wheel dirty.

Reset limt to maximum stop setting.

Loose wiring connection.

Low or fluctuating line voltage.

Locate and secure connection.

Call power company.

Shorted or welded thermostat

contacts.

Repair or replace thermostat.

Clear obstruction or replace thermostat.

Level thermostat.

Repair short or replace wires.

Replace thermostat.

Correct draft or relocate thermostat.

Replace defective primary control.

Low CO

2

less

than 10%.

High smoke

reading more

than a trace.

High stack

temperature

more than

550

F (288

C)

Net.

Reduce combustion air.

Air leaks into heat exchanger around

inspection door, etc.

Correct cause of air leak.

Adjust barometeric damper for correct

draft.

Correct burner head setting.

Clean heat exchanger.

Readjust burner.

Increase blower speed to maintain

proper temp. rise.

Increase draft.

Correct burner setting.

Increase combustion air.

Readjust registers or dampers.

Clean or replace filter.

Clean blower wheel.

Clean heat exchanger.

Replace nozzle.

Increase oil pressure to 140 psi

(965.3 kPa).