Page 5

TABLE 1

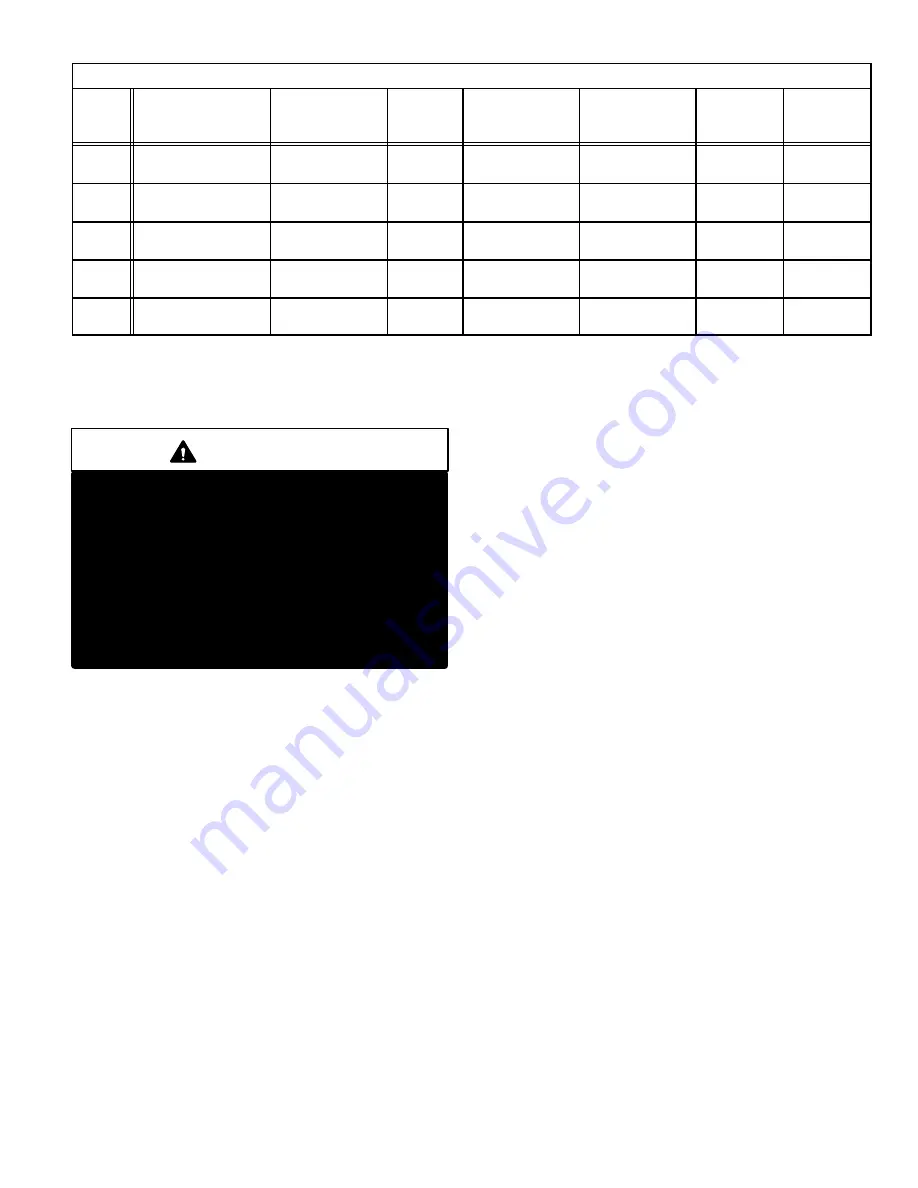

FURNACE / BURNER SPECIFICATIONS

Unit

Lennox Burner

Part Number

Burner

Model

*Initial Air

Dial

Setting

Output

Nozzle Size

(Delevan)

Pump

Pressure

Head

70

35K74

AFII 85

3.0

57,000 BTU

(16.7 kW)

0.50 X 80

A

100 psig

(689.5 kPa)

FB0

105

35K75

AFII 85

4.0

84,000 BTU

(24.6 kW)

0.65 X 80

B

140 psig

965.3 kPa)

FB3

120

35K75

AFII 85

4.5

105,000 BTU

(30.8 kW)

0.75 X 80

B

140 psig

965.3 kPa)

FB3

140

35K76

AFII 150

6.0

112,000 BTU

(32.8 kW)

0.85 X 80

B

140 psig

965.3 kPa)

FB6

154

35K76

AFII 150

6.5

125,000 BTU

(36.6 kW)

1.00 X 80

B

140 psig

965.3 kPa)

FB6

*NOTE: The initial air dial setting is provided to get unit started. The air dial setting

MUST

be adjusted after startup to

achieve proper combustion.

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during furnace

installation and service to protect the furnace's

electronic controls. Precautions will help to avoid

control exposure to electrostatic discharge by

putting the furnace, the control and the techni

cian at the same electrostatic potential. Neutral

ize electrostatic charge by touching hand and all

tools on an unpainted unit surface, such as the

gas valve or blower deck, before performing any

service procedure.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

I-UNIT COMPONENTS

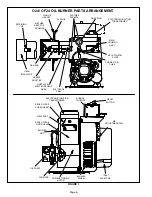

General parts orientation for the O24 and OF24 are shown in

figures 1 and 2 respectively. The O24 and OF24 burner, limit

switch and cleanout ports may be accessed by removing the

front access panel. The blower can be accessed in the O24

and OF24 by removing the blower access panel.

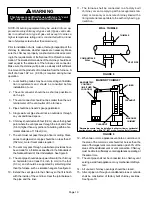

A-Burner (Figure 3)

The O24 and OF24 oil furnaces use the Beckett AFII burner.

The oil burner provides an atomized oil vapor mixed with the

correct proportion of air when it is ignited in the combustion

chamber. Oil burner minimum and maximum ratings are listed

on the unit nameplate. Proper air adjustment for these ratings

is achieved through the air adjustment dial. Set air dial to the

initial air dial setting (see table 1). After start up adjust air dial to

achieve proper combustion. Remember to tighten set screw on

air dial.

The AFII burner is available in five sizes with either a single

or two stage pump. Table 1 identifies the burners used in

Lennox units. Figure 3 shows the typical layout of the burner

assembly.

1-Combustion Air Blower / Pump Motor (B6)

The burner is activated by the primary control. A com

bustion air blower is mounted on the motor shaft. The

motor shaft also connects to the direct drive oil pump

through a coupler. The burner motor turns both the com

bustion air blower and the oil pump. The motor operates

at 3500 RPM.

Burner motors are overload protected. In the event of ex

cess motor temperature or current, the overload opens

to de-energize the motor. The overload automatically re

sets after temperature has returned to normal. Keep mo

tor clean to prevent starting switch from sticking. All AFII

motors are permanently lubricated. No further oiling is required.

2-Combustion Air Blower / Pump Fuse (F22)

(-140 and -154 CSA units only)

In the -140 and -154 Canadian units an in line fuse (F22) is

used between the line voltage from the blower control and

the blower / pump motor. The fuse is rated at 300 volts and

15 amps.

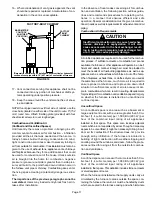

3- Pump

The O24 and OF24 oil furnaces use a single stage, 3450

RPM pump. A two stage pump is available as an option

(catalog # 65A44). The oil burner is shipped from factory

for use in a single line system. To convert the pump to a

two line system, install the bypass plug provided in the at

tached bag according to the accompanying instructions.

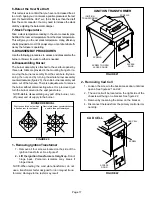

4-Burner Control (A3) & Transformer (T1)

The burner control, along with the matching cad cell, proves

flame and controls the burner. After the cad cell closes a circuit

to the burner control, the burner control de-energizes the safety

switch heater to allow the unit to operate normally. The burner

control allows 45 seconds for the cad cell to close. If the cad cell

remains open after the 45 second time frame, the burner con

trol locks out. The burner control must be manually reset by de

pressing the red reset button on top of the burner control.

Transformer (T1) is part of the burner control. T1 provides

24VAC to the low voltage components in the unit and to the

thermostat.

5-Cad Cell (R26)

Together the cad cell and the burner control prove flame.

The cad cell senses the presence of burner light (less re

sistance) to close a circuit to the burner control.

IMPORTANT-Burner should not be installed so it is ex

posed to direct sunlight or electric bulb light. If the cell

is exposed to light on start up, the burner will not oper

ate.