Page 8

TABLE 3

BLOWER MOTOR AND CAPACITOR RATINGS

Unit

Blower Motor

Part Number

Power

Volts

Hz

Phase

Capacitor

Part Number

MFD

Volts

O24-70

35K59

1/3 HP

(248.6 KW)

115

60

1

35K57

7.5

370

O24-105/120

35K59

1/3 HP

(248.6 KW)

115

60

1

35K57

7.5

370

O24-140/154

35K62

3/4 HP

(559.5 KW)

115

60

1

35K58

12.5

370

OF24-105/120

OF24-105/120R

35K59

1/3 HP

(248.6 KW)

115

60

1

35K57

7.5

370

OF24-140/154

OF24-140/154R

35K62

3/4 HP

(559.5 KW)

115

60

1

35K58

12.5

370

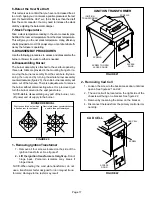

C-Blower Compartment

Blower motor (B3) and capacitor (C4), are located in the

blower compartment. The blower compartment can be ac

cessed by removing the blower access panel.

1-Blower Motor (B3) and Capacitor (C4)

All O24 and OF24 series units use single phase belt drive

blower motors. All motors used are 115V permanent split ca

pacitor motors to ensure maximum efficiency. See table 3

for horsepower and capacitor ratings.

D-Optional Accessories

Optional accessories are available from Lennox for the O24

and OF24 series units. Some accessories are in kit form which

come with instructions.

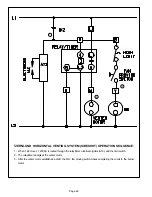

1- Continues Low Speed Blower On - Off

Switch (S68)

The low speed on off switch is a kit (catalog # 67H91) which

permits continuous low speed blower operation. The switch is

a DPDT toggle switch.

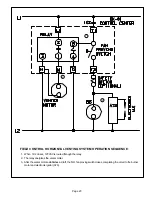

2-Economizer Relay (K43)

The economizer relay (catalog # 65G40) is used to energize

the economizer if used. The relay is a 120V coil, single pole

contact.

II-PLACEMENT AND INSTALLATION

Make sure unit is installed in accordance with installation in

structions and applicable codes.

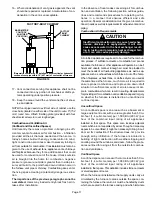

A-Piping

The piping system and it's components (oil filter, safety valves,

shutoff valves, etc.) must be designed to provide clean, air free

fuel to the burner.

An oil filter is required for all models.

Use an oil filter of gener

ous capacity for all installations. Install filter inside the building

between the tank shut-off valve and the burner. Locate filter

close to burner for easy servicing. The GAR-Ber 11BV-R or

equivalent filter (with the below specifications) is recom

mended.

Maximum Firing Rate: 10GPH (38LPH)

Micron Removal: 10

Filtering Area: 500 in.

2

(3225.8 cm

2

)

Working Pressure: 15 PSI (103.4 kPa)

Inlet/Outlet Dimension: 3/8" (9.5 mm) NPT

Flow Rate: 45GPH (171LPH)

Care must be taken to ensure the restriction of the piping sys

tem, plus any lift involved, does not exceed the capabili

ty of the oil pump. Each installation will be different. Use

the following guide lines when determining to use a single or

two stage pump.

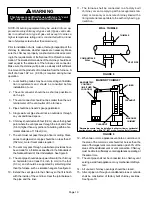

When using a single pipe system with the fuel supply level

with or above the burner (see figure 6) and a vacuum of 6" (152

mm) Hg or below, a single stage fuel unit with a supply line and

no return line should be adequate. Manual bleeding of the fuel

unit is required on initial start up. Failure to bleed air from the

pump could result in an air lock/oil starvation condition.

NOTE-As an extra precaution, cycle heating on and off

ten times after bleeding air from the pump. This will elimi

nate air in the gun assembly.

When using a two pipe system with the fuel supply level

below the level of the burner (see figure 7) a single stage

fuel unit should be used in lift conditions of up to 10 feet

(3 m) and/or a vacuum of 10" (254 mm) Hg or below. A

two stage fuel unit should be used when lift exceeds 10

feet (3 m) and/or a vacuum of 10" (254 mm) Hg to 15" (381

mm) Hg. Both conditions require the use of a return line that

purges the fuel unit of air by returning it to the fuel tank. Use

table 4 when determining the run and lift for piping.